The combi or combination boiler is a staple in many UK homes that have gas central heating, being able to quickly and efficiently heat water on demand, for both the heating and hot water supply.

If you are unfamiliar with what a combi boiler actually is and what function it fulfils, then find out all you need to know below.

Understanding Combination Boilers

Combination boilers are advanced systems that integrate the functions of a central heating boiler and an instantaneous multi-point water heater. They primarily prioritise supplying domestic hot water (DHW).

Contained within a single casing, the combination boiler houses all its operational components and is typically optimised for use within sealed central heating setups. By directly drawing cold water from the mains supply, a combination, or combi-boiler, eliminates the need for separate water tanks. It heats the hot water instantly, negating the necessity to store hot water unless specifically desired.

There are primarily two types of combination boilers: gas-fired and oil-fired. Gas boilers are more prevalent due to easy access via the nationwide gas distribution network (GDN). However, despite the slight inconvenience of storage, oil-fired boilers are considered even more efficient than gas alternatives.

Understanding How a Combination Boiler Works

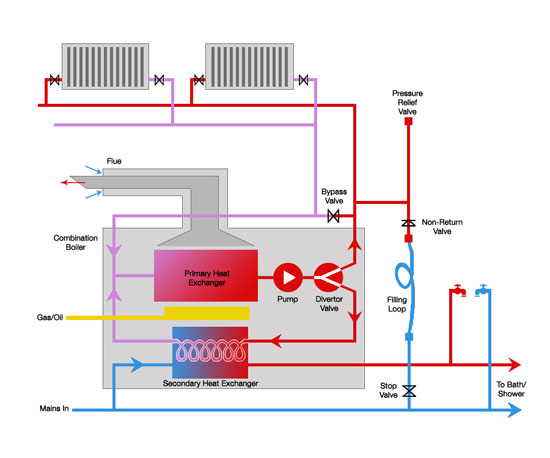

Simply put, a combination boiler operates by directing the fuel supply, typically gas or occasionally oil, into the boiler where it reaches the burners.

Activation of these burners is triggered by signals from the valves within both the central heating and hot water systems in your home. When a tap or valve is turned on to request hot water, the open tap allows water to flow.

The flowing water within the boiler passes over a paddle switch, which activates the burners in the specific section of the boiler responsible for heating water for taps, known as the Domestic Hot Water System.

Any excess heat generated is stored in a heat exchanger, a small compartment within the boiler. Therefore, when, for instance, the central heating system is operating, surplus heat in the heat exchanger is utilised to heat the hot water for taps or the domestic hot water system.

Both the domestic hot water pipes and the central heating pipes pass through the heat exchanger, allowing each system to heat the other simultaneously. This enables both systems to operate with hot water concurrently.

Diagram illustrating the operation of a combination boiler

If central heating is required but no hot water is being used, the burners will heat the pipe directly to provide hot water to the central heating system in a more efficient manner. Similarly, if hot water is needed but there is no central heating demand, the burners will operate on the pipe accordingly.

In many scenarios, turning on either the central heating or the domestic hot water activates a small portion of water within the heat exchanger. Both the central heating pipes and the domestic hot water pipes pass through the heat exchanger, where the water inside the exchanger heats the water in the pipes (indirect heating). Therefore, regardless of which water supply is requested, they are both heated through the heat exchanger in the same manner.

Components of a combination boiler – left-hand view

Construction of a combination boiler – right-hand side

Can Central Heating and Tap Water Mix?

No, they should never ever mix! The central heating system and the domestic hot water system are entirely separate pipelines, and the water in them never mixes. Thinking logically, with all the chemicals and cleaning agents used in central heating systems, mixing them would pose a significant health risk. Therefore, they are kept completely separate at all times.

Can a Combination Boiler Help Cut Costs and Save Money?

Money Saving Expert offers insights into various myths about saving money on heating, making it worth checking out for a comprehensive view.

Whether a combi boiler will save you money compared to a conventional boiler largely depends on your lifestyle. If you have a large family that frequently uses showers and baths, a combi boiler might end up costing more to run. However, if your water usage is low, a combi boiler could be more economical. However, this does change when the boiler in question is a condensing boiler.

What is a Condensing Boiler

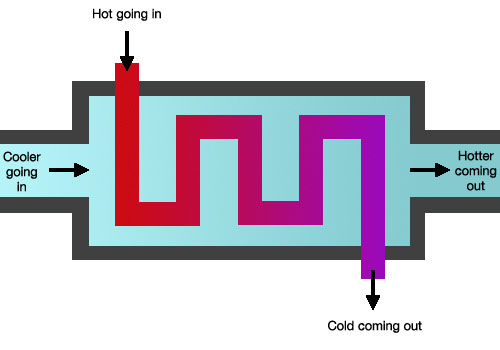

When fuel burns to warm water in the boiler, it releases hot exhaust gases. Typically, this heat promptly escapes straight out of the flue, wasting energy. However, a condensing boiler works differently. It captures the water vapour from these hot exhaust gases, condenses it into hot water, and channels it into a heat exchanger (as shown above). This recovered heat can then be utilised to further heat the water for both hot water and central heating systems.

This method is highly efficient for water heating and is now a mandatory requirement in building regulations when replacing domestic boilers.

What is a Heat Exchanger

A heat exchanger is a device that transfers heat from one medium, such as gas, liquid, or fluid, to another medium, allowing the heat from one to warm the other. Essentially, it’s a place where heat is swapped between two substances.

In a combination boiler, the heat exchanger utilises the heat from the central heating water to warm the water for the domestic hot water system, and vice versa.

An illustration showing how a heat exchanger transfers heat between two sources

Installation Tips and Requirements for Combination Boiler

Installing a combination boiler is simplified by including an expansion vessel, removing the need for a feed and expansion cistern in the roof space. Similar to a standard boiler, it consists of a gas-fired burner and a heat exchanger, both make up part of the central heating system.

In earlier models, hot water from the heat exchanger was directed to a diverter valve, which then channels it to either the domestic hot water calorifier or to the central heating circuit.

The domestic hot water system contains a compact calorifier packed with small copper tubes. When hot water is drawn, secondary water flows through these tubes, absorbing heat from the primary water in the calorifier.

For safety, where the central heating system is pressurise, it is equipped with a relief valve to prevent pressure buildup. A pressure gauge on the appliance shows the operating pressure, while a bypass valve connected across the primary flow and return maintains adequate water flow.

Combination boilers may have various flue arrangements, including open, room sealed, fan assisted, or miniature flue/condensing types.

Prior to use, the primary heating circuit of a combination boiler should always be pre-commissioned, cleansed, and treated with a corrosion protector like any other heating system.

In regions with hard water, it’s advisable to treat the secondary domestic hot water with an in-line scale reducer or water softener to prevent limescale buildup, which can reduce flow rate and water temperature.

Direct combination boilers heat secondary water in one of two ways: either by passing it through pipes alongside the primary pipes in the heat exchanger, or through a separate heat exchanger mounted atop the main one. Direct combination boilers do not require a diverter valve or secondary calorifier.

What is a Dead Leg in Plumbing Terms?

When upgrading to a new hot water system, particularly when switching from a storage cylinder or conventional boiler to a condensing combi boiler, it’s crucial to eliminate what plumbers call “dead legs”.

Dead legs are essentially unused sections of piping that were previously active but have since been capped off. Despite being inactive, they still retain water, which can lead to problems. These stagnant sections can trap air in the system, hampering the efficient transfer of heat. In severe cases, they can cause air locks, which can disrupt the entire system, prompting the boiler to shut off.

To maintain optimal efficiency and prevent potential issues, it’s essential to remove any redundant pipework, ensuring smooth water flow throughout the system.

For a comprehensive guide on dealing with airlocks in your plumbing system, check out our step-by-step tutorial on resolving airlocks.

Using Mixer Showers with Combi Boilers: What You Need to Know

Yes, mixer showers can be compatible with combi boilers, but there are some things to consider. Combi boilers supply mains water directly to the hot water system, making them a good match for mixer showers, especially thermostatic ones, as long as your water pressure is ok in the first place.

If you’re unsure about your water pressure, or know that it is too high, you can install a pressure reducing valve. Check out our detailed guide on how pressure reducing valves work for assistance with installation.

However, it’s important to note that relying on a single combi boiler for multiple mixer showers can put a huge strain on the system. The shower requires consistent mains water pressure to function efficiently. Trying to run two mixer showers off one combi boiler can often overload the boiler, leading to reduced flow and often temperature also.

If you’re considering adding a second shower to your combi boiler setup, many homeowners opt for a powerful electric shower instead.

Understanding the Filling Loop in Combi Boilers: What You Need to Know

In a central heating system with radiators, it’s crucial for water to circulate efficiently to keep your heating system working well. However, if air finds its way into the system, it can reduce the effectiveness of the pump, heating, and boiler. Additionally, if the pressure drops too low due to leaks or rusty connections, the boiler can shut down due to a fault.

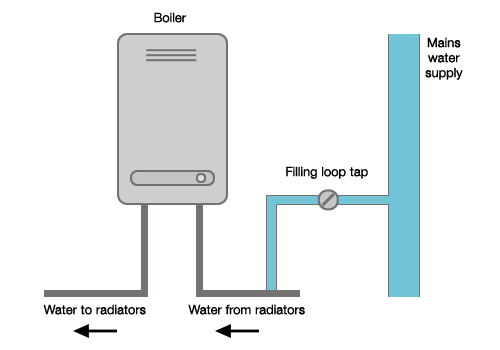

When the boiler’s pressure falls below a certain level, it’s essential to restore the pressure, and this is where the filling loop comes in. Although not technically part of the boiler, the filling loop is often located nearby for easy access.

The filling loop connects the mains water supply to the central heating return pipe of the system, which leads to the boiler. This arrangement is typically the most convenient, but the loop can be installed wherever these pipes are close to each other.

Essentially, the filling loop allows you to add more water from the mains into the central heating system, increasing the pressure and enabling the boiler to function efficiently once again.

Illustration of how a filling loop is used to top up a boiler

Your boiler will feature a pressure gauge that indicates the current operating pressure. Typically, the pressure should not drop below 1 bar, but there’s usually a green segment on the gauge indicating the range within which your boiler operates most efficiently.

Ensure your boiler pressure stays within the green range for optimal performance

When you’re ready to make a filling loop, it’s a straightforward process. Essentially, a filling loop is just a piece of pipe, typically flexible, with a pipe connector and isolation valve at each end. While you can purchase filling loops pre-assembled, making your own is completely acceptable.

One crucial detail to remember is that one of the isolation valves must be a non-return valve. This ensures that none of the pressurized water from the radiator return pipe can flow back into the mains water supply.

A non-return valve should be fitted to a filling loop

Can I Service My Own Combination Boiler?

No, it’s not allowed under any circumstances! When it comes to any work on gas or oil boilers, it’s essential to be part of the relevant competent workers scheme. For gas boilers, this means being registered with the Gas Safe Register. For oil-fired appliances, you need to be associated with OFTEC.

For your safety, always leave boiler servicing to the experts!

Combi boilers are today an essential feature in almost all homes in the UK that have a gas central heating system and for the most part, they are one of the most efficient forms of heating, however, with the huge advances in renewable technology and the push to do away with fossil fuels, they may soon be a thing of the past, but for the mean time, their the go-to hot water source for may homes.