What is a Countersink or Countersunk Hole?

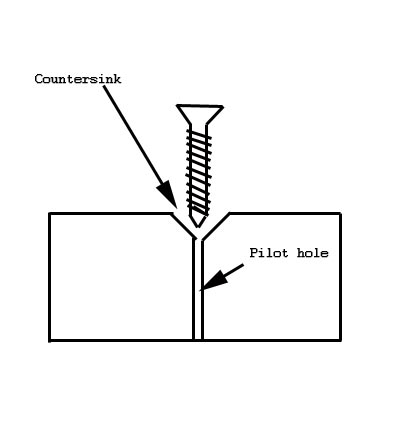

Countersinking is to enlarge and/or bevel the side of a hole to allow any given fixing to be sunk below the surface of that countersunk hole.

When the fixing has been put in, the countersunk hole can then be filled and sanded to allow the surface to be completely flat with no visible signs of fixing.

What is a Pilot Hole?

A pilot hole is a preparatory hole drilled to allow easier passage of a larger object. In this case a pilot hole is drilled to allow a screw to be driven in making its passage through the timber easier.

Because the pilot hole has a diameter of less than the screw itself, the thread of the screw can still bite into the surrounding timber making a perfectly secure fixing.

Some timbers, especially when cut into narrow or thin strips, are prone to splitting when nailed or screwed. Drilling a pilot hole and countersinking prevents this happening.

If the fixing, even a nail, does not have so much timber to displace as you force it through the timber, it is much less likely to split.

Because of the countersink hole, it can slip down below the surface of the timber, there is little chance of it splitting as the conical shape of the underside of the screw head touches the top of the timber.

Counter Sinking a Pilot Hole

How to Drill a Pilot Hole and Countersink a Screw Head

Measure the diameter of the screw, for example a number 8 screw has a diameter of 3mm, from outside of thread to outside of thread.

Drilling a Pilot Hole

A sensible size for the pilot hole is therefore 1 or 1.5mm. This will still allow the thread to cut its way through the timber without splitting it, while getting great grip on the timber. A bradawl or gimlet can be used to mark the point to place your small drill bit.

Insert the drill bit into a drill or cordless drill driver and position the tip of the bit on to the mark you have just made.

In terms of depth – it really depends on what material you are drilling (tip: to know how far you are drilling down, mark the point to stop on the drill bit with some insulation tape):

- Soft Wood: Drill down to about 1/2 to 3/4 of the total length of the screw or fixing to be inserted

- Hard Wood: Drill down to the length of the screw or just beyond

- Concrete: Again, as with hard wood, drill down a little deeper, around 1/4 to 1/2 an inch more than the length of the screw or fixing

- Stated Depth Screws and Fixings: This is really a "as it says on the tin" thing. The screw or fixing in question will have the depth of the hole needed to take it stated by the manufacturer on the packaging

Pilot holes are used almost all the time through metal as it is impossible for most screws, even run-of-the-mill self tapping screws, to force their way through. Countersinking is used also to get the head of the screw flush with, or below, the surface.

It is an excellent idea, when fixing to a concrete lintel for example, to drill a series of pilot holes, one through the other and getting slightly larger every time, until the required hole size is met.

Trying to drill a very large hole through both concrete, hard masonry and metal, will quickly blunt the drill as cutting (drilling) with a large surface area is very much harder than with a small one.

Drill bit set

Drilling a Countersink or Countersunk Hole

Countersink bits are available for this job. As mentioned above, the idea of countersinking is to sink the head of a screw or fixing below the surface of the material you are fixing to.

This really has two purposes, the first is so that the head of the screw does not catch or bind on anything e.g. in the case of screwing shelves in a cupboard down, you don’t want the screw heads at the front to bind and catch the door of the cupboard when pushed closed.

The second is if you want to hide a screw head, the countersunk hole will allow the head of the screw to sink below the material it is inserted into and can then be filled over and painted.

To drill a countersink, place the countersink bit in your drill and push down lightly on the pilot hole. For those who prefer a hands on approach, a hand held countersink tool is also available.

Drill down a little at a time until your desired depth. It’s a bit hard to give exact depths as this will depend on the size of the screw head and the size of your countersink bit.

The essence here is really to widen the mouth of the hole so that screw head sinks down. In most situations as you screw the screw or fixing down, the biting action of the threads of the screw will pull the head down below the surface anyway.

13mm countersink drill bit