The main driving purpose of Building Regulations Approved Document N is to cover all aspects pf glazing and the safety implications that are involved with what can potentially be a dangerous material.

The main focus of the document deals with impact, opening and cleaning of glazing and ensuring that safe working practice is used to prevent any accidents.

Building Regulations Approved Document N – Download Document N here

What Does Building Regulations N Cover?

Building Regulations N ensures windows, skylights, and glazed surfaces are safe for occupants and pedestrians. It covers impact resistance, breakage safety, visibility, secure opening, and easy maintenance.

The regulations are divided into four key sections:

- N1: Glazing must:

- Break safely to reduce injury risks

- Resist breakage on impact

- Be protected from accidental contact

- N2: Transparent glass must be clearly visible to prevent accidents.

- N3: Windows, skylights, and vents must open safely.

- N4: Glazed surfaces should allow for safe and easy cleaning.

N1 – Impact Protection

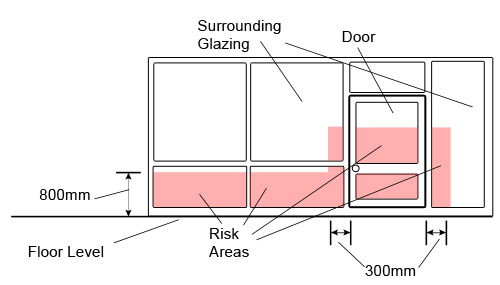

Critical Locations are high-risk areas where glass breakage could cause injury. These include glass in doors, side panels, and lower sections of walls and partitions.

For doors, risk zones are from floor to shoulder height, especially around handles and push plates.

Main risk areas around a door

In a breakage, hands, wrists, and arms are most vulnerable, followed by the body if balance is lost.

For walls and partitions, lower-level glazing poses the greatest risk, particularly to children.

Safety Measures: To reduce injury risk, use impact-resistant glass, apply protective films, or install barriers. Glass should either break into harmless particles or have protected edges, meeting BS 6206:1981 safety standards.

N2 – Glazing Manifestation

Section N2 focuses on making glass surfaces visible to prevent accidental collisions. Unlike N1, which addresses impact safety, this section ensures people can easily identify glass doors, walls, and partitions.

Large glass panels, like patio or bi-fold doors, are common in homes and workplaces. Their transparency can make them hard to spot, increasing the risk of walking into them.

Exceptions: Some glass doors meet regulations without extra markings, including:

- Doors with glass panes under 400mm wide

- Doors with a central glass panel surrounded by a solid frame

- Doors with a horizontal rail (600mm-1500mm from the ground)

- Frameless or thin-framed double doors with large handles or push plates

For clear glass walls and partitions, visibility must be enhanced with markings such as patterns, lines, or logos at eye level.

N3 – Opening and Closing Safely

Section N3 covers windows, skylights, and ventilation points, ensuring they open, close, and adjust safely. Controls for these must meet the following height regulations:

- No obstructions: Controls must be ≤1.9m from the ground.

- With obstructions: Controls must be ≤1.7m high.

- Obstructions 600mm deep: Controls must be ≤900mm high.

- Inaccessible controls: Use manual or electric remote operation.

Additionally, as per Approved Document K, windows above ground level must have restricted openings to prevent falls.

N4 – Safe Cleaning

Windows must be designed for safe cleaning, especially if there’s a risk of falling over 2 metres. The regulations allow for several solutions:

- Inward-opening windows: Must lock securely when reversed for cleaning.

- Ladders: Must be placed on stable ground. Ladders over 6m (up to 9m) should be secured at the top with eye bolts.

- Walkways: At least 400mm wide with 1100mm-high safety barriers or an anchor point for a sliding harness.

- Access equipment: Cradles or ladders must have secure fixing points for harnesses.

- Abseiling safety: Use anchor points for ropes and harnesses.

- Scaffold towers: If other methods aren’t possible, scaffolding must be on stable ground and checked for safety.

As with anything relating to the building regulations, Approved Document N is no exception – you must ensure that you are referring to the most correct and up-to-date document!

With this in mind the above notes should only be used as a guide and you should always refer to the downloadable Approved Document N available from the Planning Portal website on the link at the top of this page for the most relevant building control guidelines.