If you’ve done any DIY, you’ve likely done some painting, whether it’s walls, woodwork, or furniture.

The success of these projects depends heavily on proper surface preparation, and this is especially true for painting metal surfaces.

Preparation and painting methods vary depending on the metal object. For instance, painting a car wing requires removing all rust, applying multiple undercoats, smoothing them, and then adding the topcoat.

In contrast, painting a garden bench might just involve cleaning off rust and old paint before applying the topcoat.

If you’re painting a metal garage door, check out our guide on painting a metal garage door.

Types of Metal Paint

Like traditional paints, metal paints come in various types and from many manufacturers. The ingredients, brand, and cost can affect the paint’s quality. Generally, budget paints might be lower quality than those from reputable brands, but you can still achieve a good finish with proper preparation.

Here are some common types of metal paint:

General Purpose Spray Paint for Metal

General-purpose spray paints for metal are widely used due to their versatility. They are available in a variety of colours and types, including:

- Primer – Typically white, grey, red oxide, or high build (for filling small blemishes). Primers create a solid base for the topcoat.

- Matte and Gloss Finish – These topcoat paints provide either a dull matte finish or a shiny gloss finish.

- Metallic Finish – Produces a metallic effect using pigments and aluminium flakes of varying sizes.

- Textured Finish – Used mainly for decorative purposes. This paint has texture when touched, achieved by mixing base paint with adhesive and fine particles like sand.

- Heat Resistant Paint – Formulated to withstand high temperatures where standard paint would melt and lose adhesion.

- Acrylic and Latex – Made with an acrylic or latex base, these paints provide a strong, hardwearing finish.

General purpose spray paint can

Cellulose Paint

Cellulose-based paints, also known as Nitro Cellulose, have been around for a long time and are primarily used in the automotive industry for painting and spraying cars.

This paint consists of a clear resin base, binder, pigment, and cellulose thinners. When sprayed, the cellulose evaporates, leaving behind the coloured resin and pigment, creating the final finish.

Today, cellulose paint is rarely used except in industrial settings and classic car restoration. Its use outside these contexts is illegal due to its toxicity, as are non-compliant solvent-based paints.

As an “aggressive paint”, cellulose paint can react with other paint types, causing bubbling and blistering. If this occurs, you have two options:

- Strip all old paint back to bare metal and start anew.

- Use an isolator or sealer to seal the base surface.

Classic car cellulose car paint and paint thinners – Image courtesy of clostermann.co.uk

Two-Pack or 2K Paints

2K paints are the modern alternative to cellulose paint, offering a different application process. Made from acrylic and melamine resins, 2K paints require a second resin to trigger a chemical reaction, causing the paint to harden.

Unlike cellulose paint, which is polished for a high shine, 2K paint is flattened with fine grit sandpaper and then coated with lacquer to achieve a glossy finish.

Once cured, 2K paint is extremely durable, resisting oxidation, sunlight, petrol, and acid rain.

Note that 2K paint is for professional use only due to its toxicity. It contains isocyanate, a highly toxic substance, and must be applied in a controlled environment like a spray booth. Proper safety equipment, including air-fed breathing apparatus, is required. Learn more about safety guidelines here.

2K or Two-Pack paint with activator and 2K thinners – Image courtesy of clostermann.co.uk

Hammered Finish Paints and Hammerite

Hammered finish paints, such as Hammerite, are popular for their durability and attractive finish. These paints are excellent for protecting surfaces, repelling water, and providing a unique, textured look.

Ideal for metal fences, railings, garden benches, and some plastic and timber items, hammered finish paints can be applied directly to rusty surfaces. However, it’s best to remove loose debris first. No priming is needed, just paint and let it dry!

While traditionally applied with a brush, these paints are now also available in spray cans.

Hammered finish paints are versatile, easy to use, and durable, suitable for various items like furniture, radiators, and bikes, providing a distinctive finish with depth and texture.

Hammered finish paint

Enamel Paint

Enamel paint, traditionally known for its hard and glossy finish, now generally refers to any paint that cures to a hard surface. This makes it perfect for outdoor use and areas exposed to heavy wear, temperature extremes, and moisture.

Ideal applications include flooring, BBQs, car engines, and braking systems. Enamel paint is also great for treating timber surfaces, enhancing their resistance to rot.

Oil-based enamel paint

Paint Reactions

Paint reactions can be a significant issue, especially with professional-level paints like cellulose and two-pack. Problems arise when different paint types are applied over each other. Common issues include:

- Blisters: Raised bubbles on the surface, usually caused by reactions with existing paint or contaminants like grease or dirt.

- Wrinkles: Resembling wrinkled skin, often due to overly thick paint layers or hard edges beneath the surface.

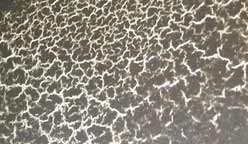

- Crazing or Cracking: Similar to dried, cracked mud, typically resulting from chemical reactions between old and new paint layers.

Cracking or crazing caused by a paint reaction

Most reactions occur due to the incompatibility of old and new paints. With standard domestic spray paint, hammered finish, or enamel-based paints, such issues are rare but possible.

If a reaction occurs, let the paint dry, then clean it off thoroughly. Ideally, strip back to bare metal. If that’s impractical, smooth the surface down to the original layer.

To prevent future reactions, apply a sealer or isolator over the old paint, following the manufacturer’s instructions (usually two coats). Once dry, sand if necessary, then proceed with priming or top coating.

Paint sealer or isolator for cellulose paint

Preparing Metal Surfaces for Painting

Preparation is crucial for a successful paint job. The method you use depends on the type of metal surface you’re working with:

Fences, Railings, Garden Furniture, etc.

For most outdoor metal items, you aim to protect and refresh them, not necessarily achieve a perfectly smooth, glossy finish. If you need a flawless finish, please skip to the next section.

Start by removing as much rust and loose debris as possible with a wire brush or coarse sandpaper. Using a power drill with a wire brush attachment can speed up the process. Always wear safety gear like gloves and eye protection.

Power drill with wire brush attachment

Though many direct-to-rust paints can be applied without thorough prep, it’s best to clean the surface well. Brush off any remaining dust and debris.

If available, wipe the surface with acetone or mineral spirits to remove any grease.

After cleaning, proceed with undercoating if needed, or apply a direct-to-metal topcoat.

Car Body Parts and Objects Needing a High-Quality, Smooth Finish

Achieving a glossy, smooth finish requires detailed preparation. Here’s how to get it right:

Remove all rust thoroughly using an angle grinder or coarse sandpaper. For larger areas, a power drill with a wire brush attachment can speed up the process. Ensure you clean down to bare metal.

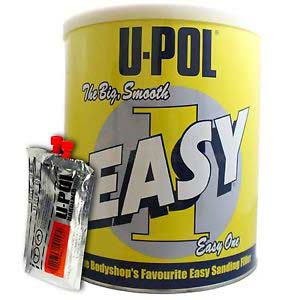

If the grinding or sanding leaves scratches, repair them with car body filler. Apply the filler after sanding down the surface.

Car body filler and hardener

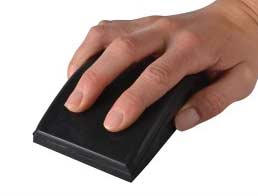

Sand the entire surface with 240 or 320 grit sandpaper. For flat or slightly curved surfaces, use a sanding block to maintain a smooth finish. For objects with intricate details, sand by hand to reach tight areas.

Rubber sanding block

Ensure no hard lines or ridges remain around bare metal areas. These can cause imperfections in the final coat. Use 400 grit wet and dry paper on a sanding block to blend the old paint with the bare metal smoothly. Follow up with finer grits (800 and 1200) to perfect the surface.

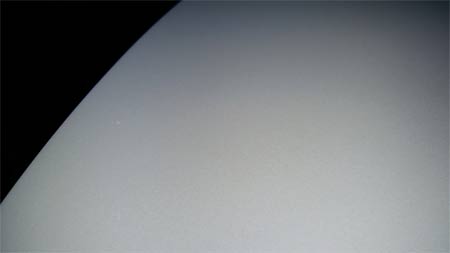

Once all imperfections are addressed, finish with 1200 grit paper to create a smooth, key-ready surface for undercoat or topcoat.

Body filler, a clay-like substance mixed with a hardener, is excellent for filling dents and minor damage. It hardens rock solid and can be sanded to shape. Note that body filler is only suitable for non-structural repairs, as it’s not as strong as the original metal.

Car bonnet with undercoat applied and smoothed

Applying Undercoat

If you’re using direct-to-rust or hammered finish paints, an undercoat may not be necessary, but applying one can still improve the top coat’s finish. Check the paint’s manufacturer guidelines first, as some paints are designed to bond directly to rust and should not be applied over an undercoat.

Before starting, mask off areas you don’t want painted with masking tape and old newspaper. Avoid placing the tape too close to the area to prevent hard lines from paint buildup.

If you’re working on a large panel but only need to paint a small section, mask off the surrounding areas rather than the section itself. Direct the paint carefully to the target area when using a spray gun.

Any overspray can be polished off with T-Cut or a similar product once dry.

Ensure good ventilation in your workspace and use appropriate safety gear, such as a filter mask, goggles, and gloves, especially when spray painting.

You will typically apply the undercoat by:

- Brushing it on

- Spray painting with a can or using a paint gun and compressor

Brushing on Undercoat

For an even finish, use a high-quality brush. Apply the undercoat in thin layers, allowing each coat to dry for at least 12 hours or as directed by the manufacturer. After the second coat dries, inspect the surface for imperfections.

If you notice dust or debris, gently sand these areas with fine sandpaper to smooth the surface before applying the top coat.

Spraying on Undercoat

Spraying undercoat with a can or spray gun requires precision. Hold the spray can or gun 25-30 centimetres from the surface. Sweep from side to side to apply an even coat. Practice to master the right distance and speed for optimal coverage.

Note that spray guns, powered by compressors, offer more control and pressure compared to spray cans, so practice with the gun to get comfortable with its settings.

After spraying, let the coat dry for about 12 hours. To achieve a smooth finish, lightly sand the dried coat with 400-grit wet-and-dry sandpaper, clean off dust, and apply the second coat. Repeat the sanding process before adding a third coat if needed.

Once satisfied with the smoothness and coverage, proceed to apply your top coat.

Applying the Top Coat or Finished Coat of Paint

The last coat to be applied is the finishing coat or top coat as it’s most commonly known. Again, there are methods of application, these are as follows:

Brushing on Top Coat

Brushing on the top coat is similar to applying the undercoat. Use a high-quality brush for a smooth finish. Apply the first coat, let it dry completely, then add a second coat. The longer the paint dries, the more durable it will be.

If desired, you can sand the first coat before applying the second for an even smoother finish, but this is optional if you don’t mind some brush strokes.

For direct-to-rust or hammered finish paints, apply at least two coats, allowing each to dry thoroughly before adding the next. No sanding of the first coat is needed.

After the final coat, let the paint cure for 24 hours before moving or placing the item.

Spraying on Top Coat

Spraying on the top coat follows the same steps as applying the undercoat. Apply at least two coats, letting each dry for 24 hours. To achieve a smooth finish, flatten the first coat before applying the second using a fine grit sand paper.

Allow the paint to cure naturally in a warm area. Rushing the drying process can lead to poor results.

For the final touch, polish the dried surface with T-Cut or a similar product for extra shine. If you encounter dust, runs, or other imperfections, these can often be fixed with polishing or a rubbing compound like G3. Practice with rubbing compounds carefully to avoid damaging the finish.

Remember, spraying paint requires practice. Drying times can vary based on temperature; warmer conditions speed up drying. In colder or damp weather, paint can mix with moisture, causing a milky haze called “blooming”. To avoid blooming, work in a dry environment. If blooming occurs, it may be polished out if not too severe.

However if it is, then worse case scenario, you will need to sand it all back and redo it.

Painting metal surfaces can be challenging, but with careful preparation and patience, you can achieve a stunning finish. Whether you’re brushing, spraying, or using hammered finish paint, a well-prepared surface will ensure excellent results you can be proud of.