There are two types of fitting to make a soldered pipe joint, one which comes with a ring of solder already inside each end of the fitting, called a Yorkshire fitting, and the other, an end feed fitting.

Copper end feed tap connectors

These connectors simply screw up to the tap after the pipes have been soldered into them

Copper Yorkshire fitting showing solder rings

Soldered joints make a neat, tidy job but require a little practice and total cleanliness to "make" properly. If in doubt, compression joints, although bulkier, are easier to manage for the DIY’er.

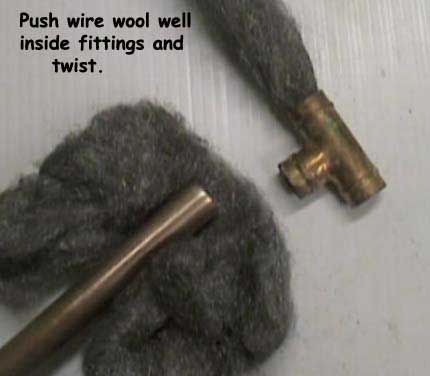

Cleaning all fittings well using wire wool

First clean both the pipe and the fitting, inside and out, with wire wool until it is bright and shiny.

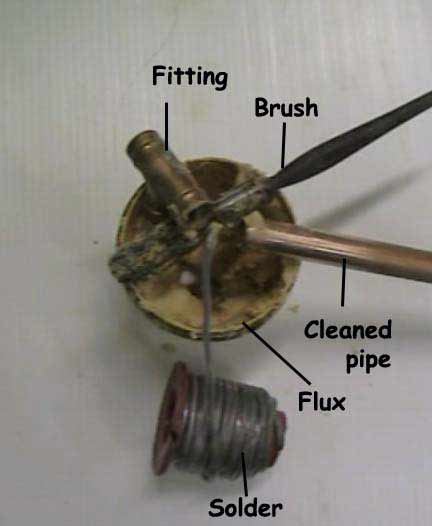

Applying flux to both sections of copper pipe to remove oxide

You will then need to apply a liberal amount of flux to both the pipe and the fitting.

Flux is a paste, which when activated by heat, removes oxides from the surface of the metal promoting fusion between the surfaces.

Use a small, clean brush to apply the flux.

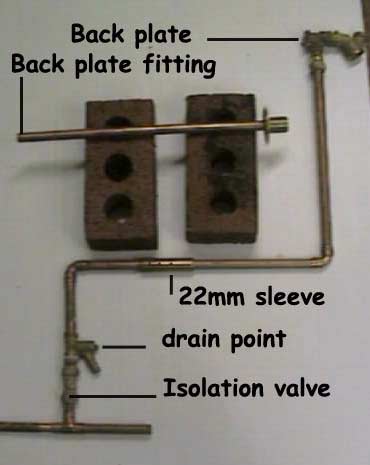

Dry fit all copper pipework together in it’s completed state

Then "dry fit" as much of the pipework together as you can, place all the pieces together where you want them and remember, with Yorkshire fittings you cannot just heat one end of the joint.

The heat will travel to the other end and melt the solder ring. This will make it impossible to connect to later on.

The picture below is of a plumbers heat mat that can be placed below or around fittings so that they can be heated (as explained below)

Plumbers soldering mat

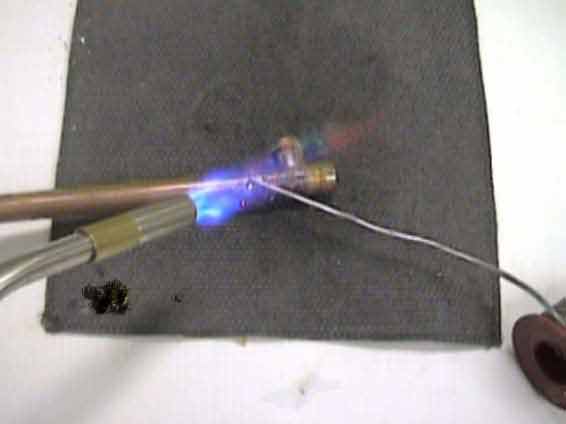

Heating the fittings and pipework using a blow torch

Using a lead free wire solder and a protection mat heat the joint with a blow lamp until, with a Yorkshire fitting, you can see bright ring of solder appearing between the fitting and the pipe.

With an end feed fitting, touch the solder stick to the joint until it melts on contact. Then run the wire round the joint for as much of it as you can get to.

The solder will melt at approximately 180°C, so it gets pretty hot!

Remove the heat when the solder starts to melt.

The application of solder is still a good idea with Yorkshire fittings to be absolutely sure of a good joint.

Make sure you have a damp rag handy, and after a few seconds, to allow the solder to set, carefully wipe the joint round. This will cool it and clean it.