Traditionally, copper was the material of choice to use for all manner of water supply pipes, whether to supply taps or feed a radiator, most pipework in the home was copper-based.

Although today, most copper pipework has been replaced using plastic (Speedfit and the likes) for it’s speed and ease of use, copper certainly still has its place, so read on to find out about copper compression joints, one of the methods used to join copper pipes together.

What is a Copper Compression Joint?

A compression joint is a type of fitting that is used to join two or more sections of pipework together by compressing an olive, which is a small brass ring that slips over the pipe and down into the fitting, plugging the gap between the pipe and the fitting, that is held in place and compressed down by a screw cap.

When installed correctly, the compression joint can create an air or water tight joint that can be used for a variety of applications, including water pipes and even gas pipes.

In terms of why copper was chosen as a material to use for such pipework applications, the main reason is because it doesn’t corrode or react easily, especially when in contact with water and other liquids, so it doesn’t contaminate or absorb whatever substance is flowing through it.

Another feature of copper that makes it especially good for carrying water is that also features natural antimicrobial properties that can help to neutralise viruses and bacteria.

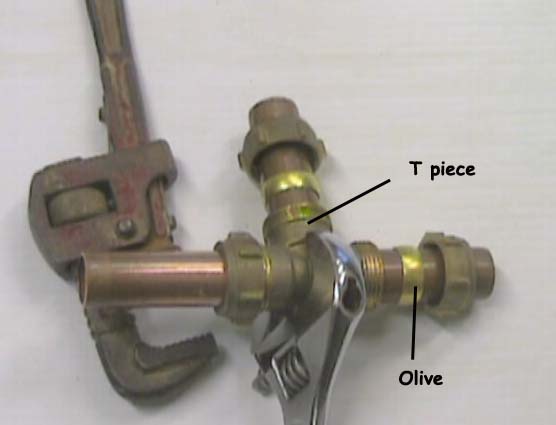

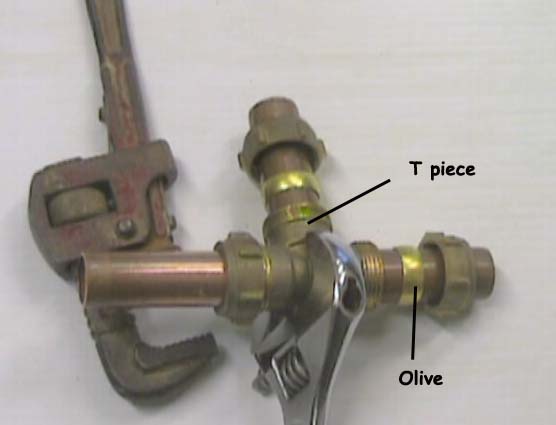

Compression T-Junction

Parts of a Copper Compression Joint

So that you fully understand the tips and guidelines in the information below, the first thing we need to do is take a look at the different parts that make up a copper compression joint:

- Compression Body/Coupling/Valve/Joint: This is the main body of the fitting and can come in a variety of different forms such as an isolation valve, a 90° bend or simply a straight joiner. Will feature a thread on either end for a compression nut.

- Olive or Sleeve: Looks like a small brass ring, this is what creates the seal. The olive is slipped over the pipe that is then insert into the coupling and once the cap is screwed down, fills the void between the pipe and coupling creating a seal.

- Compression Nut: This helps to create the seal in the joint by compressing the olive down so that it fills any gaps between the pipe and the body of the coupling once it’s screwed down tightly.

The parts of a compression joint fitting

Where are Copper Compression Joints Used?

Copper compression joints are very versatile fittings and are commonly used in various plumbing and heating applications.

These joints are particularly favoured in situations where soldering isn’t feasible or where a more flexible solution is needed.

They are also great for DIY’ers to use or those that may not be too familiar with how to solder a joint so that it’s fully sealed. Some popular uses are as follows:

Domestic Plumbing

In domestic plumbing, copper compression joints are commonly used to connect water supply pipes to fixtures such as sinks, toilets, taps and dishwashers. They are ideal for these applications because they provide a reliable, water-tight seal without the need for heat, making them safer and easier to install in confined spaces and for those new to plumbing.

Central Heating Systems

Copper compression joints are also popular in central heating systems. They are used to connect copper pipes to radiators, boilers, and water heaters, where a reliable and long-lasting joint is needed.

The ease of installation and ability to withstand high temperatures and pressures make them suitable for these situations where other solution and materials may quickly fail.

Emergency Repairs

For emergency plumbing repairs, copper compression joints offer a quick and efficient solution.

They can be used to fix leaks or replace sections of damaged pipe without the need for extensive tools or specialised skills. This makes them a practical choice for both professional plumbers and DIY enthusiasts.

With this in mind, it’s a great idea to always carry a few straight compression joiners in your tool kit for just such an occasion.

Commercial Locations

In commercial and industrial settings, copper compression joints are invaluable in a variety of systems such as gas supply lines, medical gas installations, high pressure water supplies and the similar.

This is mainly down to their durability and reliability and the fact that they ensure a long-lasting joint or coupling in these critical systems.

Renovation and Retrofits

During renovation and retrofit projects, copper compression joints offer an invaluable solution when needing to adapt old or ageing plumbing systems to new setups. They allow for easy integration of new fixtures and appliances without extensive reworking of existing pipework.

In some situations, especially period properties, you may not be allow to use newer fittings due to building control or planning regulation requirements and as copper is a traditional material it often offers and ideal solution to this problem.

Other Methods of Joining Copper Pipes

While copper compression joints are popular, there are, as we have touched on above, other effective methods for joining copper and similar pipes together.

Each method has its advantages and is suited to specific applications. Understanding these methods can help you choose the best approach for your plumbing project:

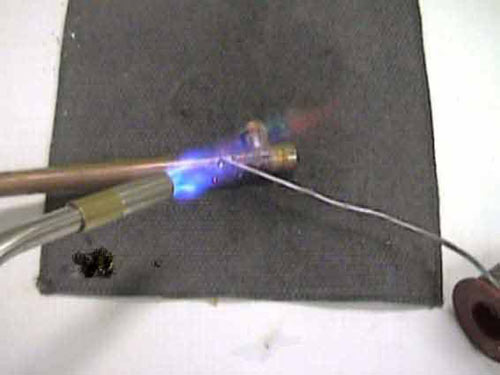

Soldering

Soldering, also known as sweating, is one of the most common methods for joining copper pipes. It involves heating the copper pipe and fitting to a high temperature and then applying solder, which melts down into the joint creating a strong, water and air-tight connection once set.

Although now a more traditional method of plumbing it is still widely used in both residential and commercial applications. However, it requires the use of a torch, flux, and solder, as well as some skill which may not be ideal for all situations or users.

Find out more about it in our how to solder project guide.

Soldering a copper pipe joint

Press Fittings

Press fittings are a modern, quick, and efficient method for joining copper pipes. They work by using a special tool to crimp the fitting onto the pipe, creating a secure and air and watertight joint.

Press fittings are ideal for projects where speed and ease of installation is of critical importance and as they do away with soldering this makes them much safer and more convenient for many situations such as tight spaces or where open flames are a major safety issue.

Copper press fitting

Push-Fit or Speedfit Fittings

Push-fit fittings, also known as Speedfit fittings in the UK (this is a brand name), offer a simple and tool-free way to join both copper and PVC pipes together.

These fittings use a rubber O-ring and metal teeth to grip the pipe securely once it’s inserted into the fitting and clicks into place. The teeth then hold the pipe in the fitting preventing it from being pulled out.

They are incredibly easy to use and are suitable for both DIY enthusiasts and professional plumbers alike. They provide a quick solution for repairs and new installations, and they can be easily disconnected if needed.

However, they are generally more expensive than other fittings and are typically used in situations where convenience is of high importance. Find out more in our Speedfit project here.

JG Speedfit PVC fitting

Brazing

Brazing is similar to soldering but uses a different filler metal than solder which has a much higher melting point.

Although this creates a very strong joint that can handle typically higher pressures and temperatures than standard solder, making it ideal for industrial applications and commercial plumbing systems that use higher pressures or temperatures, this makes it inherently trickier to use.

Due to this, brazing requires more specialized equipment and skills than simple soldering, which may not be ideal in many situations.

Brazing 2 pieces of metal together

Advantages and Disadvantages of Copper Compression Joints

As with all things, there are certain advantages and disadvantages to copper compression fittings, and ultimately whether you choose to use them or not will depend on whether the upsides out-weight any down-sides.

The most common advantages are as follows:

- Easy to install: You don’t need any special tools or particular skills, anyone can use them

- Versatile: Can be used in many different plumbing applications, for both copper and plastic pipes

- Reusable: They are easy to disassemble and can be used again and again

- No heat needed: You don’t need to solder, braze or heat in any way so are safe to use where heat and naked flames pose a significant risk

- Reliable: The compression joint is a time-tested plumbing joint, used for many, many years

As with all things there are some downsides and disadvantages, these are as follows:

- Over-tightening: If the joint is over-tightened it can kink the pipe, causing leaks

- Size limitations: Only really suitable for standard-sized domestic plumbing and not for very large or small pipes

- Appearance: Compression joints can be unsightly as they are quite bulky and less visually appealing than soldered joints

How to Use Copper Compression Joints

How that we have looked at all the different aspects of copper compression joints, what parts they are made up of, their various advantages and disadvantages etc., it’s now time to see how they fit together to form a water and air-tight joint.

Step 1: Clean and Prepare Pipe

Te first job is to clean the end of the pipe you are fitting the fitting to so that it is nice and clean and smooth with no defections. Use some wire wool or fine (600 grit) sandpaper.

Also, if there are any defects in the pipe such as dents, nicks, gauges and the likes you will need to remove these by cutting the section of pipe off, as once they are fitted into the compression joint they won’t create a good seal and you’ll get leaks

Clean and prepare the pipe you are using

Step 2: Add Compression Screw Cap

The next job is to add the screw cap on to the pipe. Simply slip it on to pipe ensuring that it is the right way around so that it can be screwed down on to the body of the joint when needed.

It should slip easily on, however if it doesn’t, then this may be a sign that there is a kink or the pipe has become misshapen somehow. If so then this will need to be rectified as you will likely get leaks.

Add the compression screw cap on to the pipe

Step 3: Add Compression Olive

Now, as you did with the screw cap, simply slip the compression olive on to the pipe before the screw cap.

Again, it should slide easily on and if it doesn’t then there is a good chance that the pipe is kinked or damaged!

Slip compression olive on to pipe

Step 4: Fit Joint Body

As with the previous 2 steps, next slip the body of the compression unit on to the end of the pipe, ensuring that it fits as it should without issue.

Again, if this is not the case, check the pipe for defects and resolve them before proceeding any further.

Fit the compression joint body on to the pipe

Step 5: Add PTFE Tape or Thread Seal

Whenever possible, wrap PTFE tape around the thread of the compression fitting. This tape will be compressed into the thread when the compression nut is tightened, sealing any large gaps within the union.

To use it, simply wrap 2 or 3 complete turns around the threads in the direction that the nut screws up.

Ideally, the water should be stopped at the olive in this type of joint and it shouldn’t need tape, but even a small leak through the threads can cause significant damage if unnoticed.

In a similar vein, various paste joint sealers are available that can also seal threads. For joints in hard-to-reach areas (like behind washing machines), plumbers often use both tape and sealer for extra assurance. If you choose to use it, use your fingers to push the paste into the threads. There are many different types available, simply visit your local DIY store or check online.

Wrap PTFE tape around the threads for additional sealing

Step 6: Screw up Compression Cap

The last job now is to screw the compression cap down on to the joint body and compress the olive up, creating a good and full water and air tight seal.

Firstly, hold the joint together, ensuring the pipe is fully inserted down into the body and then screw the cap down finger tight before finally doing it up pinch-tight using an adjustable spanner and then you’re done, good work!

Screw up compression screw cap on to body

One very important point to note is that compression joints should never be over tightened as the pipe can kink making it impossible to seal.

When tightening or loosening a compression joint, securely hold the fitting while moving the nuts using an additional adjustable spanner, this is of high importance! Twisting the pipe can cause kinks and leaks!

Holding compression joint body while tightening screw cap

If you are new to the world of plumbing, then using compression joints is a great way to get started as they are straight forward and easy to use and create a sturdy, water and air tight joint in a variety of situations.