Water underfloor heating, also known as underfloor hot water heating, is versatile and suitable for all property types, both domestic and commercial. It can connect to any heat source, including solar, geothermal heating systems, or existing or new central heating systems.

Underfloor heating offers numerous benefits over traditional radiators and is suitable for any property type. It can efficiently heat small areas like conservatories, kitchens, or bathrooms, and can also be used to heat an entire house.

Many companies supply and install underfloor heating systems, providing all the necessary components and qualified fitters if needed. Additionally, some companies offer DIY kits for self-installation.

How Water Underfloor Heating Works

Water underfloor heating uses radiant heat to provide a comfortable, even temperature across the entire room. Unlike conventional radiators that use convection heating, underfloor heating ensures you feel warm even at lower air temperatures.

This system involves laying a series of piping loops under your floor (e.g., tiles, laminate flooring), effectively turning your floor into a large radiator. The pipes are connected to your existing heating system via a manifold, which is usually placed in an accessible location for easy maintenance.

Underfloor heating operates with lower temperature water (around 50°C) compared to radiators. This is because the larger surface area of the floor doesn’t need as much heat per square meter to achieve the desired temperature. This makes your boiler more efficient, cheaper to run, and environmentally friendly.

An additional benefit is the absence of visible radiators, leaving only the room thermostat on display. This allows for more design freedom in your home without worrying about placing furniture in front of radiators. It’s also ideal for spaces with high ceilings.

The Different Water Underfloor Heating Setup’s

When considering underfloor heating, it’s important to choose the right setup for your needs. Below, we outline some of the most common configurations.

Single Zone Underfloor Heating System

In a single zone underfloor heating (UFH) system, warm water circulates from the boiler to an electrically operated zone valve, treating all connected rooms (e.g., living room, kitchen, dining room) as one zone.

If you have a combination boiler, you’ll need to zone your radiators for optimal performance. For systems with a boiler that heats a hot water cylinder, zoning should already be in place (one zone for hot water, one for radiators). You’ll only need to add the UFH manifold with a zone valve, creating a three-zone system.

When the heating is activated, either manually or by a programmable thermostat, water flows through the system to heat the specified floor area.

Multi-Zone Underfloor Heating System

A multi-zone underfloor heating system operates similarly to a single-zone system but doesn’t require a zone valve for the UFH. Instead, you’ll need to zone your hot water cylinder and radiators.

Instead of a zone valve, a wiring centre is used to independently control the underfloor system separate from the radiators and hot water system. Your programmable thermostat or time clock will activate all underfloor heating thermostats, allowing each room to be controlled via a programmable room thermostat.

This setup lets you control the temperature and heating schedule of each room individually. When a thermostat is activated, an electronic valve on the manifold opens, activating the pump and boiler. Each loop on the manifold, typically one per room (depending on room size), allows for independent control.

Mixing Manifold

The mixing manifold blends hot water from your boiler with cooler water from the underfloor heating pipes. The process starts with hot water passing through an actuator valve into the manifold. The manifold mixes this hot water with the cooler return water from the underfloor system.

This mixed water is then pumped and monitored by a temperature sensor. If the water temperature exceeds the sensor’s set point (typically between 20 and 65 degrees), the zone valve closes, and the boiler shuts off to prevent overheating.

Installing Water Underfloor Heating

Domestic water underfloor heating systems are designed for ease of installation, making them ideal for DIY projects. These systems are generally compatible with existing heating setups, including boilers, radiators, and most flooring types. Always check compatibility with your specific flooring and heating systems before purchase, just to make sure though.

Each system includes detailed installation and commissioning instructions. If you’re confident in your skills, you can lay the pipework yourself and connect it to the manifold using standard fittings. If unsure about connecting to your heating system, a plumber can complete this task in a few hours.

After the plumber connects the pipework, you can fill, bleed, and balance the system yourself, or have the plumber handle it. Next, connect the electrical components, such as thermostats and programmable controllers, to the manifold controller. These connections, which use standard 3-core and earth cables, link the underfloor system to your boiler and any zone valves.

The key to these systems is their simplicity and compatibility, with all necessary parts typically available from local plumbing suppliers.

Typical Water Underfloor Heating Manifold

Suitable Flooring Types for Water Underfloor Heating

Water underfloor heating can be installed on various flooring types commonly found in homes. Below is a list of typical surfaces and brief descriptions of the installation process:

Solid Screeded Floor

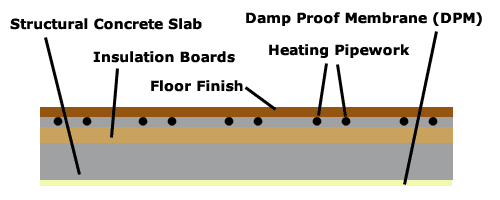

Laying water underfloor heating on a solid screeded floor is straightforward. The process involves layering heating, insulation, and screed on top of your structural concrete slab.

First, lay down a Damp Proof Membrane (DPM). Once the DPM is in place, pour a layer of concrete to create your structural slab, ensuring it is level and flat.

After the slab cures, lay rigid insulating boards on top (check with local building control for specific insulation requirements).

Next, lay and fix the underfloor heating pipework on the insulation using clips.

Finally, pour and level the screed over the pipework. Once the screed cures, you can install your chosen flooring on top.

Underfloor Water Heating Pipework Laid in Screed Floor

Solid Concrete Floor

This method is similar to the solid screeded floor, with the key difference being that the underfloor heating pipes are laid within the concrete slab itself.

First, lay a Damp Proof Membrane (DPM) on the base, followed by insulation boards (check local building control for specific insulation requirements). Then, lay and fix the underfloor heating pipes on top of the insulation boards.

Next, pour and level the concrete slab over the insulation and pipework, creating a solid concrete floor.

The primary difference from the screeded method is that this approach uses a single layer of concrete instead of separate layers for the slab and screed.

Already Insulated Concrete Floor

If your concrete slab already has insulation, installing underfloor heating becomes easier.

Start by laying 25mm timber battens over the concrete surface, spaced 400mm apart. Next, lay the heating pipes between the battens and secure them to the concrete with clips.

Finally, screed over the pipes up to the top of the battens. Once the screed cures, you can lay chipboard on top.

How to Install Flooring on an Un-Insulated Concrete Base

Follow these simple steps to install flooring on an un-insulated concrete base:

- Lay 76mm x 50mm (3” x 2”) timber joists across the concrete at 400mm (16”) centers.

- Fit insulation boards between the joists, making sure there are no gaps. (Check local building codes for insulation requirements.)

- Install underfloor heating pipes on top of the insulation boards.

- Pour screed over the pipes, leveling it to the top of the joists.

- After the screed cures, lay chipboard flooring on top, then add your choice of final flooring, such as laminate.

These steps ensure a well-insulated floor ready for your final flooring option.

How to Install Pipework in Screed on a Concrete Floor

If your base already has insulation and a concrete slab, follow these steps to lay underfloor heating pipework:

- Lay the Pipework: Position the pipework directly on top of the concrete base.

- Pour the Screed: Apply a 75mm screed over the pipework to secure it in place.

- Install Flooring: After the screed cures, you can install your preferred flooring on top.

How to Install Underfloor Heating on a Timber Floor with Screed

If you prefer using screed instead of metal plates for underfloor heating, follow these steps to create a sub-floor:

- Install Timber Battens: Nail timber battens between your existing flooring joists. Measure the depth of the insulation plus an additional 25mm to ensure the heating pipes and screed are flush with the top of the joists.

- Add Insulation: Cut and place rigid insulation boards (e.g., Kingspan, Celotex) into the gaps between the joists. Make sure there are no gaps between the edges of the insulation and the joists, this is essential!

- Lay Heating Pipework: Place the heating pipes on top of the insulation boards and secure them with insulation clips.

- Pour Screed: Spread a screed layer over the pipes, making sure it’s level and flush with the top of the joists. Allow the screed to fully cure before proceeding.

- Install Flooring: Once the screed is dry, you can lay your chosen flooring. Typically, you will start with chipboard followed by laminate or tiles. IMPORTANT: Ensure the screed is completely cured before adding natural wood flooring.

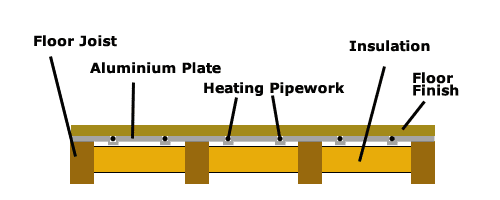

How to Install Heating Pipes Between Timber Joists with Metal or Aluminium Plates

Follow these steps to install underfloor heating pipes between timber joists using metal or aluminium plates:

- Insulate Between Joists: Start by adding insulation between all the joists. You can use either quilt insulation or insulation boards for this step.

- Choose Your Plates: Decide whether you will use metal or aluminium plates. Fix the chosen plates to the joists using nails. Important: Leave a 200mm gap at each end of the pipe run to allow the pipes to turn 180 degrees.

- Install the Pipework: Place the heating pipes in the aluminium plates. When the system is activated, the plates will heat up and evenly distribute warmth across the floor.

Water Underfloor Heating Pipework Laid in Timber Floor

How to Install Heating on an Existing Timber Floor with Metal or Aluminium Plates

Follow these steps to install underfloor heating on top of an existing timber floor using metal or aluminium plates:

- Insulate the Joists: Begin by adding insulation between the timber joists. Use either quilt insulation or insulation boards for this step.

- Lay Timber Battens: Place 20mm timber battens on top of the joists, ensuring they are spaced 400mm apart.

- Choose and Fix Plates: Decide between metal or aluminium plates for your heating system. Fix the chosen plates to the battens.

- Install Heating Pipes: Lay the heating pipes onto the plates. The pipes will heat the plates, which in turn will distribute heat evenly across the floor surface.

Underfloor Water Heating Aluminium Floor Plate

Installing under floor heating is a great idea and due to its compatibility with pretty much all existing heating systems, one that’s also fairly straight forward, even on a DIY basis.