A Planer Thicknesser is a workshop machine used in wood working which allows the planing and smoothing of large sections of timber to the exact size needed for a project.

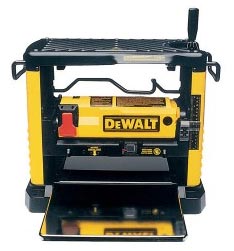

Planer Thicknesser

There are normally three parts to the Planer Thicknesser:

- Drum cutting blade

- Feed in feed out rollers

- Adjustable level table / platform to hold the timber at the correct distance from the drum blade for trimming to the required thickness.

On DIY level Planer Thicknessers, smaller models will have the table / platform as the fixed constant and the drum blade will be the adjustable part of the machine for creating the required thickness and also not even having feeding drums, this will have to be done manually by the machine operator.

A Drum blade is a metal cylinder holding (usually 2) blades which rotate at huge speeds to plane the wood. You can also find this type of blade in a power plane.

When changing the thickness of a long section of timber, rolling supports can be placed before and after the planer to support the timber plank on its entry and departure from the machine making this process safer.

Roller support stand

When planning a length of timber it is advised not to try and cut the required thickness in one go as this could make the planer jump, tear and give a bumpy, rippled finish. Plane off in small amounts until you achieve the finished thickness.

Also to achieve a flat, smooth and constant plane on one side of the timber, the other side (which slides over the work table) needs to be flat in itself.

Thicknesser

If the machine you are using does not have a self feeding action, make sure you have that little piece of wood to hand to finish pushing the timber length through so that your hands are not exposed to cutting blades.

As always with machinery that creates dust, debris and has sharp components DIY Doctor always recommends the use of gloves, dust masks and eye protection.

When using machines that can cope with long lengths of timber being machined it is always advisable to have two people operating this machine, you know it makes sense.