It pays to know which Central Heating System you have in your home and also the type of pipework it uses as this information can then help you make more informed decisions on how you heat your home.

In this guide we take a look at the different types of central heating pipework.

What are the Different Sizes of Pipework in Central Heating Systems?

There are quite a few different sizes of pipes that can be used in a central heating system and these range from 8mm all the way up to 35mm diameter pipes.

However, in domestic plumbing systems, the most commonly used sizes tend to be 15mm and 22mm diameter pipes, with 28mm also occasionally making an appearance.

In the majority of systems, 15mm pipes are used to do the bulk of the work, such as carry heated water from the boiler to the radiators.

In larger houses with 10 or more radiators, 22mm pipes are generally used to do the bulk of the water transportation around the system and then 15mm pipes are used for the final few feet and run from the 22mm supply pipe out to the radiator.

In larger systems, using a 22mm larger bore pipe ensures that a consistent flow rates and pressure can be maintained at all times.

What are the Different Types of Boiler Setup?

Along with the types of pipework that your central heating system is using, it’s a great idea to also know what type of boiler the system is using. In the UK, the most common types of boiler setup are as follows:

- Combi Boiler: One of the most common types of boiler found today in the UK, this type of boiler runs both the heating and the hot water.

- Condensing Boiler: Again, another common boiler found in the UK, especially today and probably one of the most efficient boilers today, as above, these boilers handle both the heating and the hot water. Their efficiency comes from the fact that they recycle the hot gases produced when the unit burns fuel.

- Conventional Boiler: The most basic form of boiler available, they simply use a fuel such as gas or oil to burn and create the heat that runs both the heating and/or hot water in a property.

- System Boiler: An older form of boiler, this type only generally runs the heating in a home, however some can also heat a supply of hot water that’s stored in a water tank.

What Materials are Used for Central Heating Pipework?

Choosing the right pipework material is crucial for the efficiency, durability, and ease of installation of a central heating system. The most common materials used for central heating pipework are copper and more recently, plastic (PEX). Each material has its own advantages and is suited for different types of installations.

Copper Pipes

Copper has been the traditional material that’s used in plumbing and heating systems for decades. It’s valued for its durability and resistance to corrosion. Copper pipes can handle high temperatures and pressures, making them ideal for central heating systems.

One of the biggest benefits of copper is that it has natural antibacterial properties, helping to prevent the growth of harmful bacteria in the water supply.

One downside however is that copper is more expensive than some alternatives, and installation often requires professional soldering skills.

Plastic Pipes (PEX)

Plastic or PEX (cross-linked polyethylene) pipework is becoming increasingly popular in modern heating systems. These pipes are flexible, easy to install, and cost-effective.

Unlike copper, plastic pipes can be bent around corners without the need for fittings, reducing potential leak points.

PEX is also highly resistant to corrosion and scale build up. However, it’s not as heat-resistant as copper, so it’s usually insulated and must be installed away from direct heat sources.

Stainless Steel Pipes

Stainless steel is another durable option, often used in systems where extra strength and corrosion resistance are required. Stainless steel pipes can last for many years with minimal maintenance.

One downside is that they are more expensive than both copper and plastic, but their longevity and resistance to damage from rust or extreme conditions make them a worthwhile investment for certain installations.

Different Types of Central Heating Pipework

Now that we have looked at the various different sizes of pipes used in central heating systems and what they’re made from, it’s now time to take a look at the different types of pipe layout.

Single Pipe System

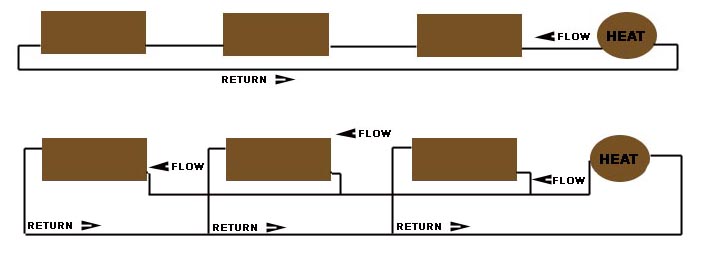

As you may have guessed from the name, this system operates through a single pipe which comes from the boiler, running along at floor level to each radiator in the system.

A pipe is branched off the feed pipe to take hot water to (usually) the top of the radiator where it passes through the radiator, heating it up and then comes out the other side, a little cooler.

It’s then passed back into the supply pipe and is mixed back in with the hot water in the main feed pipe again.

On the whole, the single pipe system is a very inefficient in terms of how it mixes the used cooler water from the radiator back in with the hot water from the boiler.

In most cases, this means that the first radiator is normally very hot, while the last in the system, having mixed with a great deal of cool water, is usually pretty much cold.

Double Pipe or 2 Pipe System

With a double or 2 pipe system, this was developed to solve the major efficiency issues that the more traditional single pipe system suffered with.

To resolve it, the system was developed to feature two separate pipes that run to each radiator.

One pipe would be used to run from the hot water outlet of the boiler to the inlet on each radiator (the flow pipe), supplying them with hot water for heating and the other would run from the outlet of each radiator and be used to pipe the colder water from each radiator back to the boiler to be re-heated for use once more (the return pipe).

By not mixing the 2 together means that the hot water remains hot throughout the whole system and to each radiator, making it much more efficient. It also means that the system can be balanced much better.

In the event that all of the radiators are closed off, to enable the system to circulate correctly a pressure release valve is fitted between the feed and return pipes, which allows the pump to then circulate the water in the system.

The image below shows the pipe layout of both a single and 2-pipe system, single at the top and 2-pipe at the base.

Single and Double pipe systems

Micro Bore System

In a micro bore system, large pipes (up to 28mm) carry hot water from the boiler to a manifold, which splits the flow and return paths.

Radiators are connected via 8mm flexible copper pipes, with a maximum length of 5, which ensures the best levels of efficiency.

A key drawback is that adding new radiators is not an easy job. Unless there’s an unused port on the manifold, you have no choice but to use a new manifold to supply the extension.

As with the 2-pipe system above, if all radiators are turned off, a bypass valve fitted allows the water in the system to keep circulating.

Timers, motorised valves, and pumps direct water where it’s needed, but with many components, issues can and very often do occur.

For more information regarding central heating please see all of our central heating projects especially our project on Radiator Problems.

To ensure that any central heating system operates at its most efficient level, it’s essential that it features 2 pipes, one for a hot feed and one for the cold return. This way the 2 are not mixed and the hot water will remain hot for each and every radiator in the system.