The petrol cut-off saw stands as an indispensable tool on pretty much every construction site, ready to tackle a diverse range of cutting jobs. From concrete and steel to asphalt and masonry, this ultimate cutting tool is also known by several aliases such as stone saw, disc cutter, concrete saw, wet saw, or colloquially, the Stihl saw (a popular brand name).

When dealing with robust materials like concrete or stone, choosing the right tool is paramount for efficiency. In this guide we delve into the essentials of using petrol cut-off saws, ensuring you’re well-equipped for any cutting task that comes your way.

What is a Petrol Cut Off Saw and What’s it Used for?

The petrol cut-off saw is the professional’s tool of choice on construction sites when any serious cutting jobs arise. Armed with a potent petrol engine and the correct cutting disc, this powerhouse effortlessly slices through an array of materials like concrete, steel, asphalt, steel and cast iron.

Primarily, on construction sites, the cut-off saw is the go-to solution for tasks involving resizing and shaping bricks, blocks, and paving slabs, trimming pipework and RSJ’s and other heavy-duty cutting tasks. While alternatives like the angle grinder exist, their abilities are surpassed when compared to the speed and precision offered by the cut-off saw.

For ambitious DIY projects, such as retaining wall construction, laying a new patio, or even full-blown extensions, opting for an angle grinder might seem plausible. However, the wise move is to consider renting a cut-off saw from your local hire centre. The investment quickly pays off in time savings and enhanced efficiency, making your DIY endeavours smoother and more enjoyable.

Understanding Parts of a Stone Cut-Off Saw

Before using a petrol cut-off saw it is absolutely essential you are familiar with its components. Let’s take a moment to explore the key features that constitute a stone cut-off saw.

The essential components of a petrol cut-off saw

The image above highlights the crucial parts of a cut-off saw, focusing on elements vital for smooth and safe operation. Here’s a detailed breakdown of each component:

- Cutting Blade: Powered by the engine, the cutting blade swiftly rotates to slice through various materials, with different blade types available for different cutting needs.

- Blade Guard: Safeguarding non-cutting areas of the blade during rotation, the guard protects operators and those in proximity from potential injuries.

- Water Surpression System: Attachable for dust suppression, a dust suppression water bottle dispenses water over the cutting blade, minimising dust during the cutting process.

- Carrying Handle and Rest: The rest stabilises the saw during operation and at rest, while the handle facilitates easy transportation and secure operation.

- Throttle and Throttle Lock: The throttle enables the user to rev the engine, adjusting the cutting disc’s rotational speed, with the throttle lock preventing accidental activation.

- Choke: Facilitating easier starts for a cold saw, the choke adjusts the fuel-to-air ratio during the starting process.

- Pull Start: Initiating engine turnover, the operator pulls the pull start to start the cut-off saw.

- Fuel Tank: Housing fuel for the engine, the tank features a screw-on cap to prevent spillage.

- On/Off Switch: Initiates the start and shutdown of the cut-off saw.

- Engine: Powering the cutting disc, the engine is the heart of the cut-off saw.

- Drive Belt Tensioner: Regulating the cutting disc’s rotation, the tensioner adjusts the drive belt’s tightness.

- Anti-vibration Mechanism: Minimising vibrations passed on to the operator during saw operation.

- Decompressor: Eases the starting process by releasing engine compression; once started, it ensures full compression and correct running.

- Air Filter: Positioned at the rear, the filter cleans air entering the engine’s induction system, requiring regular maintenance.

- Fuel Pump/Purging/Bulb Pump: Facilitating easier starts, the pump draws fresh fuel into the carburettor, ensuring smooth operation.

Understanding Cutting Discs for Petrol Cut-Off Saws

Choosing the right cutting disc is crucial for the optimal performance of your petrol cut-off saw and more importantly, the safety of the user. In essence, there are two primary types of cutting discs or wheels designed for cut-off saws: composite/abrasive discs and segmented diamond discs.

Composite/Abrasive Discs for Stone Cut-Off Saws

Composite discs are versatile cutting tools designed for various materials. Unless otherwise specified by the manufacturer, composite discs can effectively cut through the following materials:

- Steel

- Concrete

- Natural stone

- Cast iron pipes

- Asphalt

- Bricks and blocks

Important tip: If you’ve used a composite cutting disc with water, it’s crucial to dispose of the disc after completing the job. Avoid reusing it, as the disc may warp and misshape as it dries out. Reusing a distorted disc can lead to failure and compromise safety in future use.

Composite abrasive cut-off saw blade/wheel

Segmented Diamond-Tipped Discs for Precision Cutting

Segmented diamond-tipped discs are capable of cutting through various materials. In most cases, these discs can effectively cut:

- Clay – including bricks and pipes

- Natural stone

- Concrete and reinforced concrete

- Granite and marble

- Asphalt

- Hard and abrasive materials

Important Note: It’s crucial to understand that not all diamond discs are the same. There are different types based on the methods used to attach diamonds to the segments. These include lower-quality vacuum brazed and sintered attachment blades and higher-quality laser-welded blades.

Generally, lower-quality blades are suitable for cutting softer items like concrete and asphalt. In contrast, higher-quality laser-welded blades excel in cutting tougher and thicker materials at higher speeds.

Diamond cutting disc or wheel for a cut-off saw

Pre-Use Checks for Cutting Discs

Before fitting either composite or diamond-tipped discs into your cut-off saw, it’s crucial to perform a thorough inspection. This ensures the safety and effectiveness of your cutting operation. Here’s what to look for, and if any issues are present, it’s best to replace the disc:

- Worn Disc: If the disc is so worn that the retaining plates (or thrust washers) need to touch the material being cut to perform the task.

- Mounting Hole Damage: Check for any damage to the mounting hole or arbour hole. A misshaped hole can prevent the disc from being securely held in place.

- Flat or Misshapen Areas: Inspect the disc for any flat or misshapen areas. Uneven surfaces can cause irregular cuts and potentially lead to the saw kicking back.

- Segmented Blade Damage: If using a segmented blade, check for any damage to the individual segments. Damaged segments can result in uneven cutting, sticking, or unexpected kicks during operation.

- Discolouration: Discard discs with discoloured edges, a sign of overheating. Overheating can lead to warping, uneven cutting, and an increased risk of the saw kicking back.

- Never Use Dropped Discs: Discard any disc that has been dropped, as it may have unseen damage, warping, or hairline fractures, posing a risk of binding or disintegration during use.

- Intended Use: Use the disc as intended. If it’s a wet cut disc, ensure it’s used with a water suppression system. If you have a dry cut disc, use it without water.

By adhering to these pre-use checks, you ensure a safer and more efficient cutting experience with your cut-off saw.

Proper Steps for Attaching a Cutting Disc to Your Cut-Off Saw

When fitting a cutting blade to your cut-off saw, follow these steps to ensure a secure and effective attachment:

- Place the cutting disc on the drive mounting of the saw, ensuring the centre is fully in place and sitting flat.

- Slide the retaining washer (or thrust washer) onto the disc mount and screw it up finger-tight.

- Once finger-tight, use the provided spanner to tighten the retaining nut according to your saw’s manufacturer specifications.

Quality matters, especially with cutting discs. Invest in the best quality discs within your budget. While the most expensive diamond-tipped discs aren’t always necessary, choose reputable manufacturers that guarantee a certain production standard. Cheap discs may seem like a deal, but the potential risks outweigh the initial savings.

Never use circular saw or wood cutting blades in a cut-off saw. Stick to discs specifically designed for cut-off saw use.

Check the side of the disc for information on the materials it’s designed to cut. Additionally, understand if it’s meant for wet or dry cutting and note the maximum rotational speeds, information often stated on the cutter itself.

Here’s a crucial reminder for diamond discs: If the disc appears unused or practically new but won’t cut, the bond might have covered the diamonds. To address this, perform a “dressing” by cutting abrasive objects like bricks or concrete blocks. This process wears back the bond and exposes a fresh diamond edge.

Considering a Petrol Cut-Off Saw: To Buy or to Hire?

Wondering whether to buy or hire a petrol cut-off saw? This decision essentially boils down to how frequently you plan to use it.

If you’re a tradesperson engaged in extensive building projects, from constructing extensions and entire houses to laying patios and handling ground works, the answer is a resounding yes. Investing in a cut-off saw becomes a valuable addition to your toolkit. Despite the initial cost, the tool is likely to pay for itself in a very short time.

On the flip side, if you’re a dedicated DIY enthusiast and your days aren’t spent on construction sites, the expense of buying might not be justified. Opting to hire a cut-off saw as needed could be a more cost-effective choice for occasional use.

Ensuring Safety: Health Precautions for Petrol Cut-Off Saws

Using a petrol cut-off saw entails inherent health risks, given its powerful, high-speed cutting blade. Safety measures must be diligently followed to prevent accidents, injuries, or even fatalities.

When operating a petrol cut-off saw, adhere to the following essential guidelines:

- Undergo comprehensive training before using the tool, whether on-site or when hiring from a shop.

- Prior to use, thoroughly inspect the saw for any damage or defects. Do not use a damaged saw; repair it first.

- Examine the cutting disc for signs of damage, cracks, fractures, damaged segments, or warping. Replace it if there’s any doubt about its condition.

- Always wear the required personal protection equipment (PPE), including eye protection, gloves, sturdy work boots, and more importantly a decent respirating mask (FFP3 at minimum).

- Place the saw on a flat, level surface before operation.

- Avoid speeding up the run-down time of the saw by using your hand to slow the disc.

- Ensure bystanders are at a safe distance and wearing appropriate safety gear.

- If the object you’re cutting creates a lot of dust, make sure of the saws dust suppression system (if it has one).

- Do not attempt to cut objects using the wrong type of cutting disc.

- Be vigilant about kickback; a jammed disc could throw the saw backward.

- Never operate the saw while standing on an unstable surface, such as a ladder.

- Maintain a firm grip on the saw with both hands at all times.

- Have a secure footing and ensure balance is maintained throughout operation.

- Never lean over the saw while it’s running.

- Ensure the object being cut is fully supported to prevent it from pinching the disc.

- Never tilt the saw while in operation to prevent warping or shattering of the disc.

- After completing a job, remove the disc and store it flat.

- If you notice unusual vibrations or sounds, stop the saw immediately, inspect it thoroughly before considering further use.

- Avoid wearing loose-fitting clothing that could get caught in the saw.

- Ensure there are no hidden pipes or utilities in the object you’re cutting.

- Do not cut into objects that are not securely clamped or may be structurally affected by cutting into them.

Additionally, it’s crucial to wear proper safety clothing, including flame-retardant materials, sturdy boots, gloves, eye protection, ear defenders, hard hat, and, importantly, a suitable respirator or face mask for the material being cut.

Another significant health concern arises from the dust and microscopic fragments generated during the cutting process, particularly when working with materials containing crystalline silica.

To mitigate risks, wear a respirator or face mask at all times to protect against inhalation of respirable crystalline silica (RCA) found in the dust, that’s linked to serious health conditions such as lung cancer and silicosis. Additionally, be cautious of potential asbestos content in some materials, especially old concrete pipework, and take necessary precautions to protect against asbestos dust.

Large amount of dust created by cut-off saw

How to use a Petrol Cut-Off Saw

Now that we know exactly what a cut-off saw is, what it looks like and what it does it’s time to look at how to prepare your work area and the object you’re going to be working on, how to get the saw started and then how to use it.

Step 1 – Preparing Your Workspace

Your first task is to find a suitable area for your cutting work. Choose a space that’s clear of obstacles, providing ample room for easy movement without the risk of collisions.

Considering ventilation is crucial, the volumes of dust pose a significant challenge. While modern saws often have dust suppression systems, they might not capture all of it. Opt for a well-ventilated area where any present dust can disperse effectively.

Ensure the ground is flat and level, allowing the item you’re working on to sit securely without rocking or shifting. Your stance matters too, so stand with your feet flat and level, maintaining a steady posture throughout the process.

An outdoor workspace provides ample space and ventilation.

Step 2 – Inspecting Your Saw

Before diving into your cutting tasks, take a moment to thoroughly examine your cut-off saw. Check for any signs of damage or defects that could impact its performance.

This scrutiny extends to the cutting disc as well. If there’s even a slight suspicion of damage, do not proceed! Replace it with a brand-new disc, ensuring optimal functionality.

Refer to the “Health Implications” section above for a comprehensive list of areas that require inspection.

Thoroughly check your saw, including the cutting disc or wheel.

Step 3 – Fuel Mixing Made Easy

If you’re new to petrol-powered tools, especially if you’re under 30, you might not be familiar with the 2-stroke petrol engine.

Unlike most engines that have a sump filled with oil to lubricate the engine, the 2-stroke engine requires a mix of special 2-stroke oil in with the petrol. As the engine burns the petrol, the leftover 2-stroke oil provides the necessary lubrication.

It’s crucial to get the right mix of 2-stroke oil and petrol for optimal performance. Consult your saw’s user manual for the exact ratio. If not specified, contact the manufacturer for guidance.

Typically, the ratio is around 1:25, meaning 1 part oil to every 25 parts petrol (approximately 40ml of 2-stroke oil per litre of petrol). Ensure your ratios are accurate for efficient operation.

A handy tool for this task is the 2-stroke mixing bottle, as shown in the image below. The markings on the bottle guide you to the precise points for both substances, making the mixing process a breeze. These bottles are affordable and a wise investment!

2-stroke fuel mixing bottle for precise measurement of oil and fuel

Step 4 – Starting Your Petrol Cut-Off Saw

In this example, we’ll guide you through starting a Stihl TS410 cut-off saw. While these steps are specific to this tool, most other saws on the market follow a similar process (though symbols may differ slightly). Keep these guidelines in mind for a smooth start.

Before diving into the steps, take note of a few key points:

- Throttle Lock: Many saws have a throttle lock to prevent accidental throttle pressing. Squeeze the throttle lock to enable throttle movement

- Choke Usage: Only use the choke when starting the engine from a cold state

- Decompression Valve: Press the decompression valve button before attempting to start the engine

Cold Starting a Cut-Off Saw

- With one hand, press the throttle lock down and then squeeze the throttle in. With the other hand, slide the control slide switch down to START and hold it there with your thumb. Still holding in the “START” position, release the throttle and the throttle lock. The slide control should remain in the START position

- Move the choke lever to the cold start position

- Press in the decompression valve button once

- Press the manual fuel pump bulb around 5 or 6 times to pump fuel into the carburetor. This needs to be done even if there is fuel already present in the bulb

- Ensure the saw is placed firmly on the ground on its stand. Apply a little pressure to the rear of the saw where the air box is to keep the cutting disc up off of the ground. This can be done by resting your knee very gently on top of the rear handle.

- Make sure you have a solid footing on the ground

- Hold the top handle with your left hand grip the handle of the starter pull cord with your right hand

- Genetly pull the starter pull cord until you feel a little resistance and then give it a good strong tug. Don’t just let go of the pull cord as this can damage it. Guide it back into the housing using your hand

- The cut-off saw should now start, but if not, repeat the above steps 5 – 8 until it does

- Once the engine is running, it’s a good idea to let it warm up. Give the throttle trigger a little squeeze to rev it slightly. You should see the control slide switch jump to the I position. This is the normal running position

- After running for a few seconds, move the choke lever to the normal running position

- Once the engine has warmed up the saw should then be ready to use

Slide control switch moved into the START position ready to start cut-off saw

Choke moved into cold start position

Press in the decompressor button once

Pump the fuel bulb several times to draw fuel into the carburetor

Hold the cut-off saw firmly using the front handle and resting your knee gently on the rear handle

Hold the front handle of the saw firmly with your left hand and grip the pull start with your right hand

Pull the pull cord until you feel it engage

After revving the engine slightly, the slide control will jump to the I position

Choke moved to the normal running position

Warm Starting a Cut-Off Saw

If the engine of your saw has been turned off for around 5 minutes or more, follow the steps below

- Squeeze both the throttle lock and throttle in and slide the control slide switch to the START position and hold it in place. Release the throttle and throttle lock and then move your thumb from the slide switch. It should remain in the START position

- Move the choke to the warm start position

- Press in the decompression valve

- Pump the fuel bulb 2-3 times to pump in some fuel

- Place the saw down on a solid flat surface on its stand

- Ensuring you have a solid footing, rest your knee gently down on the air box to lift the cutting disc away from the floor

- Hold the top handle with your left hand and grip the pull cord handle with your right hand and pull gently until the starter mechanism engages and then give it a firm tug to start the engine

- If it doesn’t start first time, repeat the above until it does

- Allow the engine to run for a good few seconds and then flick the choke lever to the standard running position

Choke moved to warm start position

Choke moved to normal running position

Note: If your saw’s engine has been turned off for 5 minutes or less , to start it, ensure that the choke is in the standard running position.

Step 5 – Using a Cut-Off Saw to Cut Concrete, Masonry, Steel, and More

Now that you’ve mastered starting the saw, let’s dive into the exciting part—using it for precise cuts. Remember, safety first!

Before diving into your cutting task, ensure your workpiece is securely clamped or placed on a stable surface. This prevents unexpected movements that can lead to injuries or damage to the cutting disc.

It’s crucial to prevent the item you’re cutting from closing in on the cutting disc, as this can damage the disc and cause the saw to “kick”, moving unpredictably. This is a significant safety risk!

If you’re cutting an item spanning a gap, add proper support on each side of the cut to maintain stability.

In our example, we’ll demonstrate cutting a concrete block in half for a wall construction project.

To ensure precise cuts, mark the cutting line on the item using a cold chisel or bolster.

Using a brick bolster to score a cutting line onto a concrete block

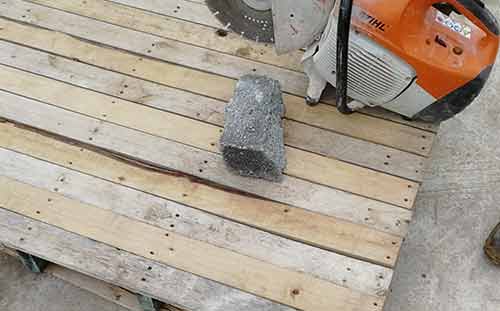

- Place your workpiece on a solid surface; here, an old pallet provides a stable base to prevent the saw from cutting into existing surfaces.

- Start the saw (following the tips above) and let it warm up.

- After warming up, rev the saw for a few seconds to ensure everything is in proper working order.

- With all systems go, grip the saw firmly and position yourself in front of the item, ensuring a solid footing.

- Press the throttle lock, squeeze the throttle almost fully to reach full revs.

- Lower the cutting blade slowly until it engages with the surface, feeling it “snatch” and pull you forwards or upwards if working vertically.

- Keep a firm grasp, ensuring full control. Cut along your marked line, applying steady pressure. Let the saw do the work—avoid forcing it downward to prevent unnecessary strain.

- Avoid cutting through the item in one go; cut in stages, e.g., through the top half from front to back, then down through any remaining material.

- After finishing the cut, release the throttle and allow the disc to run down before withdrawing it from your workpiece.

Concrete block placed on solid wooden pallet for cutting

With the saw up to speed, the cutting wheel was lowered down to the concrete block

Cutting concrete block in stages

Step 6 – Safely Wrapping Up Your Stone Cut-Off Saw Session

Now that your cutting tasks are completed, it’s crucial to follow these steps for a safe shutdown:

- Allow the cutting disc to naturally come to a stop before withdrawing it. Place the saw down on a stable surface, ensuring it rests securely on its stand.

- Never attempt to slow or stop the disc manually or by making contact with another surface!

- Move the control slide switch to the OFF/STOP position to cut the engine.

- Never leave a running cut-off saw unattended, always turn it off, even if you plan to step away for just a few seconds!

- Once turned off, remove the cutting disc and store it flat in a secure location. Then, carefully pack away your saw.

- Before storing, if the saw is particularly dusty or wet, give it a quick brush and cleanup to ensure it’s ready for future use.

Slide switch turned to off position on saw

Petrol cut-off saws are very dangerous tools and if not treated with care and respect can cause serious injury, but when used correctly they are indispensible when it comes to cutting concrete and masonry, steel, asphalt and many other materials and surfaces.