This section is all about mechanical fixings such as screws, nails and nuts and bolts. They are sometimes called fasteners. We aim to make sure that you understand which type of fixing is appropriate for whichever job that you are doing. There are a huge range of screw and nail types, which we cover in detail in the projects above.

You will have all the information you need to select and use the right fixing, but crucially you will understand why as we explain how each type of fixing works.

This section is all about mechanical fixings. We have a whole section that is about Glues Adhesives and Chemical Fixings which will help you understand when you can (and should) use a chemical fixing. Often you will uses chemical and mechanical fixing in conjunction with each other.

When it comes to fixing to particular materials, we have a section which approaches this whole topic from that angle. So if you are working on a particular material and want to make a fixing to it but don’t know what to use or how to use it, please see our section on Fixing to Types of Material.

For the tools that are needed to apply these fixings or fasteners we have specific projects such as the different types of hammer and different types of screw drivers that are available. These projects show the different types of tools, how and when to use them.

What are Fixings Fastenings or Anchors?

There can be confusion between the definition for fixings and fastenings or anchors. This is largely because the word “fixing” is a gerund, which means that it can be used as a noun or a verb.

Austin Williams the Architect, project manager, author and Director of the Future Cities Project, defines fixing as:

Fixing is the act of holding and securing an object in place (sometimes called the fixing method)

While:

An Anchor or “Fastener” is for holding down and securing connectors used for fixing (sometimes called the fixing device)

Ultimately this is all semantics, and so long as you ensure that whoever you’re talking to understands what you mean, it doesn’t really matter if you fix and object with a fixing, a fastener on an anchor. In most cases you will “fix” something to a base material, and this material will determine to a significant degree which anchor should be used.

The definition by the concrete society is a good one, although they (understandably) limit it to concrete:

Fixings are for the connection of items to the concrete [or other materials] once it has hardened, such as supporting brackets

It is worth noting that these definitions apply equally well to chemical fixings as they do to the mechanical fixing that we are referring to in this section.

How Fixings, Fasteners and Anchors Fixing Work – The Forces that Fixings Resist

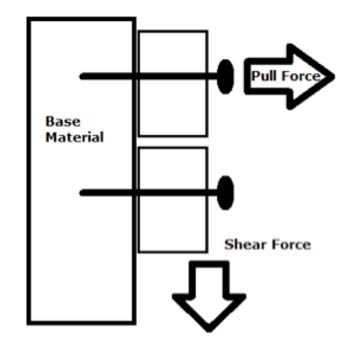

There are two main forces that anchors or fixings need to resist:

- Pull Forces: These are forces that pull in the same direction as the fastener if fitted. The force pulls along it’s axis.

- Shear Forces: These are forces that act against the side of the anchor. The force is exerted at right angles to the axis of the anchor.

Some anchors will be better at resisting different forces than other. For example, nails are good at resisting shear forces but less effecting at pull forces.

For more information about how these forces work, we have a complete project with clear animations about how all these forces work.

The Pros and Cons of the Different Types of Mechanical and Chemical Fasteners

As we have already mentioned there are mechanical and chemical anchors, however there are two types of mechanical fastener, or more accurately, there are two ways in which mechanical fasteners work:

- Expansion Anchors – these fasteners are anchored into the base material because they expand in it creating friction which holds them fast. They include wall plugs (rawl plugs), through-bolts and sleeve anchors

- Under cutting Anchors – these anchor the fastener into the base material by undercutting or screwing into it. The undercut bites against the base material and holds the fixing fast, as the thread of a self-tapping screw holds the screw in place when pulled

Chemical fasteners are usually resins that are injected into the base material which then bond with it to hold the fixing in place.

The pros and cons of the different types of fastener are:

- Damage to the Base Material – Mechanical fasteners will apply stresses to the base material and this can damage it particularly if it is fragile or brittle

- Cost – Mechanical anchors are usually cheaper both to buy and install than chemical anchors

- Ease of Installation – Chemical anchors tend to be more difficult to install than mechanical ones. The margin of error for say drilling a hole to fit a mechanical anchor is bigger making them a less skilled job

- Time – Chemical anchors need to set and bond which take some, typically up to 24hrs, before they can be loaded. Mechanical anchors can be loaded immediately

- Spacing – Because of the lack of stresses that they cause, chemical anchors can be fixed much closer together if required

- Loading – All the different types of anchors come with different loading ratings so it is very difficult to generalise. Chemical fasteners will bond better with some base material so it is worth reading the specific guidelines for the product you intend to use