You might think that a hammer is just a hammer but in fact there are many different types of hammer out there each with it’s own specific job. You might also think that there are all the same parts of a hammer but again these can differ depending on the type of hammer.

In this guide you will learn all about the different types of hammer and also the different parts of a hammer.

Safety Advice for when Using Hammers

You use a hammer to hit things and therefore hammer safety generally involves making sure that you cleanly hit the thing you intended, and that any fragments from where the strike is made are contained safely, or protected against.

In many cases you will need to protect the object that you are hitting with your hammer so that it is not damaged by the blow.

Here are our tips to make using your hammer safer:

- Wear goggles; especially when you are driving in nails, breaking concrete or other materials that could shatter or fragment on impact.

- Always use the head of the hammer, not the side to strike with. The metal is not hardened here, is much thinner where the handle passes through and can be damaged. The hammer is also unbalanced making it harder to make a clean strike and you will generally find it harder to see what you are striking too.

- You hammer does need some maintenance. If the hammer handle is held in the head of the hammer with wedges these can work loose or the handle can shrink if it wooden. This means that the head can come loose and slip down the handle hurting your hands or even fly off. Tip: Soak the head of hammers with wooden handles to make the wood expand which will secure the head to the handle again. You might need to add new wedges if required.

- The face can become polished with use and can slip off nails when struck; roughen the face with some abrasive paper to prevent this happening.

- Protect delicate work from hammer blow marks by using a piece of scrap wood to adsorb the blow. Place the off-cut onto the surface you wish to hit and then strike this rather than the object directly; it will protect it.

- To protect delicate wood work, use a punch to sink the nails without striking the wood itself.

- Always use the right hammer for the job you are undertaking; It makes the task easier and will help to avoid possible damage to the hammer, yourself and the project that you are working on.

The Parts of a Hammer Explained

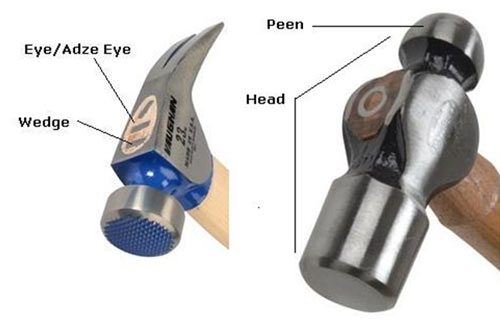

A hammer is made up of the following parts: A handle, a cheek, a claw (sometimes), a neck, a bell or poll and a face. Despite some having slightly different parts, essentially pretty much all feature these core elements.

Although a hammer is essential a very simple tool, as you can see from the above there is some terminology that has developed to describe the various parts.

The different parts of a hammer

Parts of a Hammer

The basic shape and design of a hammer has not change for hundreds of years. Traditionally the handle was made from wood, most commonly ash or hickory. Now this is changing with the introduction of other materials which can absorb the shock from the hammer blow better or are considerably lighter and/or stronger.

In most cases the head of the hammers is made of metal and this is the part of the hammer that shows the greatest variation. Here are some of the common parts of hammer heads:

The different parts of a hammer head

Parts of a Hammer Head

Generally the handle is attached to the head through a hole in the head (the eye). The handle is secured by driving wedges into the wood of the handle to make it expand and fit the hole tightly. This allows the handle to be changed should it become damaged.

Types of Hammer and What they are Used For

There is a considerable range of hammers that can be bought, and the average person will only have 2 or 3 in their tool bag, and this is probably all that they will ever need.

These are the most common types of hammer that people use today, both for DIY and in the trade:

Claw Hammer

Claw Hammers are the most common type of hammer and probably the one that comes to mind when most people think about a hammer. They are very versatile and can be used for a great many jobs so are an absolute must for any tool bag. The most common weights are from 16 to 24 ounces (455-680g).

Claw hammer

The claw is used as a lever; it generally has a notch which is used to lever out nails from timber. The claw is inserted under the head of the nail so that it catches – this can take a little jiggling about. The nail is then levered out by pulling back on the handle and using the curve of the claw as the fulcrum. The claw can be used to lever other things, such as floorboards, but excessive use can put strain on the join between the head and handle, so check this regularly.

Cross and Straight Pein, Warrington or Joiners Hammers

4 oz Cross Pein Pin Hammer

These are different hammers with a variety of uses which are determined largely by the weight and strength of the head. They all have a similar shaped head with a cross or straight pein (also spelled "Peen") on the opposite side of the head to the Bell (or Poll).

Warrington, Joiners and Cross Pein Pin Hammers are all mainly used for wood working. The cross pein is used to start off the tack or nail. If you hold a small nail or tack in you fingers it can be difficult to hit the head of the nail without hitting your fingers.

The cross pein allows you to gentle tap the nail between your fingers without striking a finger or thumb. The pein can be at right angles to the handle (straight pein) or parallel to it (cross pein), but most commonly you will see the cross pein as this is most useful for starting off tacks and small nails.

The heavier cross or straight pein hammers are mostly used for shaping metal.

Ball Pein

These hammers are sometimes called engineers or mechanics hammers. They have a rounded, hence ″ball″, pein which is used for shaping metal, closing rivets and rounding edges off metal pins and fasteners.

Peening, a metal fabrication process, is little used these days, and involved hardening a metal surface with repeated impact. This was mostly done by the flat face of the hammer, in fact.

16 oz Ball Pein Hammer

Ball pein hammers range from 4 oz – 2 lb. (55 – 1100g), although the majority are in the region of 8 – 12oz (110 – 165g). The handles are traditionally wood, usually Ash or Hickory, although modern materials are now used as they suppress the vibration well.

Club or Lump Hammer

This is used for hitting cold chisels to break masonry or simply to bash things up like a tiny sledge hammer.

3 lb Club hammer

They are usually double faced and have a wood or resin handle. 2-3 lb is the typical weight, although they can weight as much as 4 1/2 lbs. These are a vital tool for a builder and will be used throughout a building site.

Sledge Hammer

3 lb Sledge Hammer

These are similar hammers to a club hammer, except they have a longer handle and tend to be a little heavier (3-14 lbs).

They are used for breaking up masonry, stones and concrete. They are also useful for driving in stakes. Real force can be delivered by swinging the hammer like an axe; the longer handle will provide huge momentum and hitting power when combined with the weight of the head.

A variation is a Deadblow Hammer. This is another hammer for minimising damage to the surface while designed to deliver the maximum power on impact. They generally work by having an internal cavity filled with steel or lead shot. This evens out the power of the impact in the blow, enabling a more powerful blow to be delivered without risk of damaging the target as reduces rebound when strike is made; the head of the hammer stays on the surface begin hit.

Remember your hammer safety!

Mallet

A mallet is a wooden block on a handle. It is used to hit and drive a chisel, knock in dowels or to tap wooden joints together. This is an essential tool for a joiner or carpenter.

Carpenter Mallet

They are typically made of beech (a hardwood) and are used where a metal hammer might do damage to the piece or project being worked on or the other tools, such as the chisel.

Generally the head will be slightly tapered to ensure correct contact with the piece being worked on.

Even More different Types of Hammers

So far we have covered the most commonly used type of hammers, but there are a range of less frequently used hammers and hammers that are used for specialist jobs. Here is a selection:

Aluminum Hammers

These are soft faced hammers that are used for molding metal without damaging the surface being molded.

Aluminium Hammer

Blocking Hammers

Used for shaping metal on a block or anvil.

Blocking hammer

Copper and Hide Hammers

This hammer’s head has copper at one end and rawhide at the other. It is used for shaping metal when you do not want hammer marks on it, such as on car bodywork.

Copper and Hide Hammer

Geologist Pick Hammers

This is a small, spiked pick axe for knocking fragments of rock. On the other end of the head is a flat face for breaking up small rocks. Other than geologists looking for fossils, brick layers sometimes these hammers to pick out old brickwork joints.

Geologist’s pick hammer

Lath Hammers

Hammer with a small axe on one end for cutting and nailing laths for plaster.

Lath Hammer

Planishing Hammer

This is a metal working hammer, used to smooth out hammered metal which still has the hammer marks on it from forming the shape.

Planishing hammer

Roofers & Slaters Hammers

This hammer is used by roofers. It has a spike at one end for putting nail holes in slates. At the other end is a hammer to knock in the nails which hold the slates to the roofing battens. In the middle it typically has a claw for pulling (removing) nails.

Roofers and Slaters Hammer

Scaling Hammers

These hammers are used for removing scale and build up from boilers and huge pipes.

Scaling Hammer

Scutch Hammers

A scutch hammer is used for scutching (knocking) off old mortar from bricks and paving.

Scutch Hammer

Tack & Upholstery Hammers

These hammers typically have one magnetised or slotted head for starting off upholstery tacks, and then you can change round to normal head to finish the nail off. Both faces on the head are small and delicate.

Tack Hammer for Upholstery work

Brick & Mortar Hammers

These hammers used by builders sometimes have a chisel (pein) on both ends, or sometimes they can have a hammer one end and chisel the other. Typically they are used for breaking bricks neatly.

Brick and Mortar Hammer

Drywall Hammers

A dry wall hammer will have a small axe on one end of the head and a hammer face on other. Axe is used for cutting plasterboard for pipes and making other holes or opening in the plasterboard. Sometimes they have a magnetic head for finding studs with screws/nails in, which can be very useful. Traditionally a lath hammer would have been used but now plasterboard is used there is no need to a lath hammer except in older buildings.

Drywall Hammer

Rubber and Soft Hammers

These are hammers that are used like mallets and are designed not to damage the surface which you are bashing, albeit walls, timber, chisels etc. The can have interchangeable, shaped faces which are useful for woodwork, easing tight doors / windows trim fitting including chrome and rubber surrounds or for light assembly work – knocking things into place.

Rubber hammers with a variety of shaped faces

Sprig and Framing Hammer

A framing hammer used for nailing the framework of timber buildings, longer and heavier than a standard claw hammer, usually with a straight claw. This is not to be confused with a Sprig Hammer which is used by picture frame makers.

Framing Hammer

Power Hammers – Nail Guns

These are power tools that drive in nails, tacks and staples, and are often called Nail Guns. They can be electric or powered pneumatically or by gas. They are designed to reduce the hard work where there are a lot of nails to be hit home, such as when fitting floor boards.

DeWalt Heavy duty nail gun

Form more information about using nail guns safely, please look at our project on using a nail gun.