SPEEDFIT® plumbing has been about for sometime. Another name is Quick fit plumbing which does exactly the same job and also sometimes it’s known as Push Fit fittings. The time saved using SPEEDFIT® fittings and pipe is absolutely fantastic.

Many die hard traditional plumbers will not use it but as the technology has improved and all fittings now comply with all British Standards, we are happy to use it. It is not ideal in places where it can be seen because even the best plumber in the world cannot make a run of this type of pipework, complete with fittings, look neat. The pipe does tend to curl and bow a little and the bends etc…. are a little awkward.

The fittings, by necessity, are bulky and unsightly but my goodness when you can complete the plumbing in a bathroom in half the usual time you have saved your customer a fortune.

Installation time is reduced by a massive 40% and the flexibility allows you to get pipework through places where you would not normally be able to access. This can save a lot of unsightly surface work.

It is really important not to over bend the pipe as it can kink which will reduce the water flow. If you have a tight corner to get round, use a fitting rather than try to bend the pipe too much.

SPEEDFIT® pipes are ideal for retro fitting bathroom items such as concealed showers as the pipes can be hidden much more easily than copper.

Note: It should be noted that these types of fittings should not be used with chrome plated pipes. This is due to the fact that the gripping mechanism or ring inside the fitting is not quite strong enough to bite into the chrome plating and secure the joint.

Concealed plumbing for shower using SPEEDFIT® pipes and fittings

Benefits of SPEEDFIT® Fittings

Because the pipes and fittings are plastic there is no scale build up and the elasticity of the pipe greatly reduces the likelihood of pipes bursting in freezing conditions although they should certainly still be lagged. The pipes are metal free and non toxic and being able to use long lengths of pipework reduces the number of fittings required.

SPEEDFIT® should not be used for fuel oil, compressed air or gas installations.

The image above shows some SPEEDFIT® plumbing in place for a shower valve to be fitted when the studs have been plaster boarded and the tiling done.

It’s flexibility allows for easy adjustment and anyone who has ever fitted a mixer valve for a shower will be grateful for this. Note the two stopcocks at the bottom which will be hidden by the bath. Due to teh ease of use with these fittings, there is no point not fitting isolation valves whenever one might be needed.

What Can I Use SPEEDFIT® Fittings For?

The fittings are quite a bit more expensive than copper fittings but again, the labour saving element makes up for that.

SPEEDFIT® is interchangeable with copper so any run that is to be visible can simply be carried on in neat copper plumbing with soldered joints.

The performance specifications are within the guidelines of normal domestic activities and this includes central heating.

They have been passed for mains and indirect cold water systems, vented and unvented hot water systems, vented central heating systems and sealed central heating systems if temperatures and pressures comply with BS 7291 Parts 1, 2 & 3 class S.

Before we go into the project and look at how to use SPEEDFIT®, here are a few things you must not do:

- Never use a hacksaw to cut SPEEDFIT® pipe, always use a pipe cutter shown below. If you push a pipe with a rough end into one of these fitting the burrs may damage the O ring which will lead to a leak

- Do not use damaged or scuff pipes

- Do not push your fingers into any fitting as the teeth may cut you

Use pipe cutters when cutting plastic pipe

Making Connections With Plastic Pipe Fittings

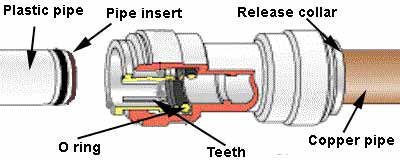

The pipe is not as rigid as copper and when the fittings are connected, especially with hot water, the ends of the pipe can become a little compressive.

For this reason every time we use a pipe fitting, whether it is a straight coupling, a bend, an isolation valve or a stop-cock, we push pipe inserts (as seen in the below image) into the end of the pipe. This keeps the pipe rigid and will not allow the fitting to crush the end.

Insert for pipe ends

Different Types of SPEEDFIT® Fitting

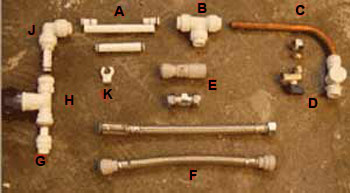

The image below shows a range of the available fittings and just below the image is a description of what the fitting is for and how it should be used.

Different types of fittings available

- A: A short length of pipe showing a pipe insert at each end. Pipe inserts must be used every time a joint is effected. The insert gives additional strength to the end of the pipe as it is clamped between the teeth of the fittings. The image above shows how a pipe insert works (titled: "Insert for pipe ends")

- B: An equal T piece. This can be inserted into a run of pipe allowing the water supply to be tapped into for the fitting of, for example, an outside tap

- C: A length of copper pipe going into an appliance tap

- D: Another type of appliance valve called a ball valve or stop tap. This type of valve is most often used on washing machines where easy operation in the event of a problem is required

- E: These are isolating valves (See isolating valves project) which spedfit make in a chrome plated finish or a plastic finish

- F: The bottom F is a flexible coupling used for connecting two pipe ends where a tight or difficult bend is required. They are also very useful for repairing a burst pipe when the burst has been cut out. The top f is a flexible tap connector with an isolating valve fitted in line

- G: A stop end. Just push onto the end of a pipe and the water is stopped. Must be used in conjunction with a valve of some kind!

- H: A stop tap or stop cock tap can be added to reduce of totally stop the flow of water in a run

- J: A 90 degree bend is used to create a right angle bend in a run of pipework

- K: Pipe clips which should be used every 500mm with speedfit pipe

There are many other types of fittings but these are the ones which are used the most. For every fitting available in copper compression or Yorkshire, there is a SPEEDFIT® equivalent. The table at the foot of the page shows some of the other fittings available.

The image below shows isolating valves in place with copper feeds at one end and plastic running up to service the taps. Simple connections, done in seconds.

Turn off water easily with plastic isolation valves

As mentioned above, the table below lists so of the other types of fitting available and also features an image to help you identify what each one looks like.

Table of the Most Common SPEEDFIT® Fittings

| Fitting Image | Fitting Description |

|

Brass to plastic tap connector |

|

Straight Coupling |

|

Reducer straight coupling |

|

Equal elbow |

|

Reducing Elbow |

|

Stem elbow |

|

Underground connector |

|

Straight tap connector |

|

Angled tap connector |

|

Equal T piece |

|

Angled tank connector |

|

Branch stem |

|

135 degree stem elbow |

|

Reducing Tee |

|

Stop end |

|

Female Coupler tank connector |

|

Tank connector |

|

Pipe repair kit |

|

Plastic back plate elbow |

|

Two way divider |

|

Conversion connector |

|

Slip connector |

|

Hose connector |

|

Wing back elbow |

|

Brass back plate elbow |

|

Stop valve |

|

Appliance tap |

|

Appliance Tee |

|

Angled stop valve |

|

Double check valve |

|

Plastic service or isolation valve |

|

Brass service or isolation valve |

|

Brass stop valve |

|

Plastic service valve with tap connector |

|

Chrome service valve with tap connector |

|

Brass drain cock |

How do SPEEDFIT® Fittings Work?

How a SPEEDFIT® coupling works

Cross section of a SPEEDFIT® coupling

This images above shows just how advanced the technology is with these fittings.

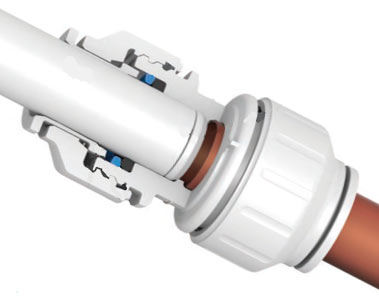

SPEEDFIT® fittings such as the ones shown above have a release collar which can be pushed in to release the pipe. There are also fittings with screw collars which are used to clamp the pipe in place and are simply unscrewed to release.

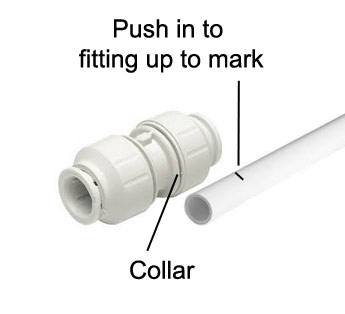

To make a water tight joint using SPEEDFIT® the first job is to cut your plastic pipe to the correct length and ensure the end you will be inserting in to the fitting is square. As stated, don’t be tempted to use a hacksaw, use a pair of plastic pipe cutters (as seen below).

Plastic pipe cutters

Once your pipe is cut to length, push a pipe insert in to the end that will be pushed into the fitting. Before you do so, check both the insert and the pipe itself for any score marks that could cause leaks and also for any burrs or rough edges that could damage the O-ring in the fitting.

Make sure the insert is pushed in firmly and it fits nice and snug. If it is sloppy or can be moved easily it is not the correct one and the chances are that the joint will leak.

Plastic pipe insert

Before you go ahead and push the pipe into the fitting, it’s a good idea to make a mark on the pipe to the depth of the fitting so that you know it has been pushed all the way up to the pipe stop.

Unscrew the locking mechanism slightly so that there is a gap between the screw cap and the collar and hold the end of the pipe so that the tip is level with the collar and then mark the pipe with a pen where it is level with the top of the screw cap. This is how far the pipe needs to be pushed in to create a suitable seal.

Push pipe in to fitting up to depth mark

One thing to be aware of is that the O-rings within these fittings can be easily damaged if you simply ram the pipe in. To reduce teh risk of this happening, as you push the pipe in, twist it. This will also help to get the pipe down until it touches the pipe stop a bit easier.

Ensure the twist lock cap is in its unlock position and gently push the pipe in to the fitting, using the previously mentioned twisting action and once pushed all the way in, screw the cap down until it touches the collar. Don’t overtighten it, it just needs pinching up.

Once your fitting has been assembled, hold the fitting in one hand and pipe in the other and give it a gentle tug as it you were trying to pull it apart. If all is well there should be no movement at all but if there iis, check the fitting and ensure that the locking twist cap is tightened correctly.

You have now completed your first SPEEDFIT® fitting!

As we mentioned earlier in this project page, aside from the Twist and Lock fittings there are standard push-fit fittings. These are pretty much the same except they don’t feature any twist-lock caps. The pipe is simply pushed in to the fitting up to the collar and the gripping mechanism automatically locks on to the pipe and holds it in place.

Standard push-fit fitting

Disconnecting SPEEDFIT® Plumbing Fittings

Disconnecting a fitting is as easy, if not easier, than connecting up. Each of the two types has a slightly different process:

- Standard Fittings: Simply push the collet down squarely until it touches the main body of the fitting. This will release the gripping mechanism and allow you to gently pull the pipe out

- Twist Lock Fittings: Unscrew the cap so that it is loose and then push down on the collet with equal force all the way around to that it depresses squarely until it touches the body of the fitting and then gently pull the pipe out

Collet gripping mechanism release collar

The collet can in some cases be quite tricky to push back down and in these cases, a collet release tool may come in handy.

Collet release tool

SPEEDFIT® has really turned the plumbing world on its head as it has made DIY plumbing much easier for those that have little to no experience of plumbing. The image below shows just how simple even something as complicated as installing a stopcock can be.

Stopcock fitted using Speedfit fittings