If you are planning on a patio, paving or driveway project, unless every aspect of your design or the space you are working in is totally square and true and the slabs or pavers you are using are exactly the right size to fit, chances are you are going to have to cut some items to size.

Cutting solid concrete paving or patio slabs and also brick pavers can seem like a tricky job if you have never done it before but fortunately there are several different ways this can be done, read on below for all you need to know.

Is There a Right Or Wrong Method for Cutting Slabs and Pavers?

Each different method of cutting patio slabs, pavers etc. can be more suited to a particular type than, volume, shape etc. but there is certainly no right or wrong choice in terms of what method you choose.

For example, using a stone saw or angle grinder will give you nice straight cuts at speed but if you are going for a rustic and authentic looking pathway or patio using Indian sandstone, large slate or similar then arrow-straight edges and corners may spoil the look.

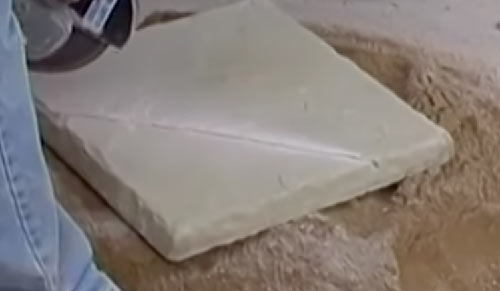

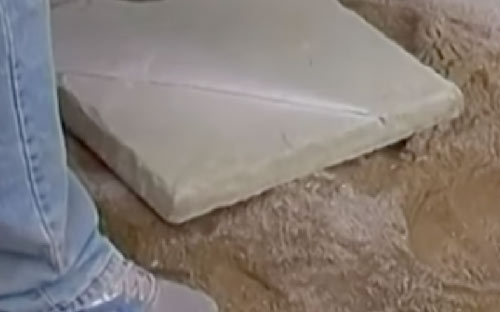

Straight cut made in patio slab using stone saw

In the case of the above, to get an authentic and rustic look you would probably be best off making your cuts using a hammer and bolster chisel, but using tis technique can be very time consuming and also take a fair amount of practice to master.

However buying or hiring a block and slab splitter can again allow you to make a large amount of cuts in a short time once you have mastered the technique of using the machine, but unless you are going to be using it every day, it won’t make any economic sense to purchase one.

Large block or slab splitter

In general the best route to take when cutting any form of slab is what’s best for your situation and wallet. If you have loads of accurate cuts to make, hire a stone saw or splitter, but if you only have a few cuts to make and you’ve already got an angle grinder in the garage buy or hire a decent diamond cutting disc.

Diamond cutting disc for use with an angle grinder

Health Considerations When Cutting Brick, Stone and Concrete

Breathing in large amounts of dust, especially silica dust is extremely hazardous to your health and using any type of saw to cut solid materials such as stone and concrete creates a huge amount of dust so in order to help reduce health risks when undertaking activities such as these the Health and Safety Executive introduced a set of guidelines that must be followed.

Where possible methods other than cutting should be used e.g. using a splitter as opposed to a saw but when a saw is the only practical solution a dust suppression system must be used.

In the case of a stone saw this is a water distribution system that is built into all stone saws. On the side of the saw you will notice a standard hose pipe attachment where a hose can be connected or the pipe from a portable suppression tank.

As the saw runs, water jets spray water over the cutting disc which waters down the dust preventing it from spreading.

Water suppression system on a stone cutting saw

However water and electricity don’t mix so you cannot use such systems with electric stone saws or angle grinders.

For these the LEV (local exhaust ventilation) method is used. This is where the tools blade guard acts as a collecting device and prevents the dust from spreading and in turn the guard is also connected to a dust extractor which connects to a large industrial vacuum that sucks it all away.

Employing these protective measures is the law and these guidelines should be followed at all times.

Finally cutting using a high speed disc can cause fragments and splinters of concrete, stone etc. to fly off in all directions and in a similar way so can hammering and chiseling.

With this in mind, full PPE (personal protective equipment) should be worn at all times including gloves, goggles, hard hat, suitable footwear etc. and even a suitable FFP3 mask or respirator.

Additionally you should also ensure that you don’t perform any cutting around glass surfaces (windows, doors, patio doors) or when any passers by or spectators by get pelted with said flying debris.

How to Cut Paving and Patio Slabs and Block Pavers

Now we have looked at some of the reasons governing what particular method you may opt to use to cut your slabs or pavers it’s time to see how each is done.

Using a Hammer and Bolster/Chisel to Cut Patio Slabs and Pavers

Cutting blocks, pavers, stone and other hard materials was traditionally performed using a hammer and chisel (or bolster). With todays more modern saws becoming the preferred method due to their speed and ease of use, the humble hammer and bolster has now taken more of a back seat.

Despite this they are by far the cheapest method and with a little practice once you have the technique you can create amazingly clean cuts, however this does take a lot of practice and in reality if you don’t do it on a daily basis then your cuts are likely to be fairly rough, so it’s probably best if you use one of the below methods if you need a nice clean cut.

In terms of the tools to use there are a vast array of different types of hammer and chisel available today but in general a decent lump hammer around the 1kg mark, a 75mm bolster chisel for making the cut and also a 20mm cold chisel for trimming and fine tuning will do the job.

Lump hammer, 60mm bolster and cold chisel used for cutting and shaping patio slabs, pavers and other stone items

- Firstly, measure the exact dimensions of the gap you need to fill and note these measurements down

- Next, mark the measurements on the slab that needs cutting using a piece of chalk or decent marker pen and straight edge such as a spirit level. As chalks and markers tend to be quite thick ensure you note which side of the marked line you need to cut

- With your slab fully marked place it on a solid flat and level surface and ensure there is no debris between the slab and the surface it’s on as these can cause the slab to crack as you’re cutting it. To absorb some of the shock and vibration that can cause the slab to crack place it on an old folded towel

- To cut the slab, take your 60mm bolster chisel and place it on the cutting line at the very start. Ensuring you are holding it dead upright, strike it with the lump hammer firmly but not too hard.

- Repeat the above again, moving the chisel along the line as you go until you have created a channel running the length of the cut. With the first pass done move back to the start and do it again and repeat until you have a channel 4-5mm deep

- In a lot of cases even a slight weakening in the surface of such an item can be enough to allow it to split easily so using a rubber mallet give it a few good taps along the length of the cutting line if it splits, great, if not go back and cut the channel a little deeper and repeat until it does

Slab positioned on solid cutting surface

Cutting channel created along cutting line in slab

Paving slab cut in half using a hammer and bolster

Using an Angle Grinder to Cut Slabs and Pavers

As mentioned above you will need to ensure that your particular tool has a vacuum attachment on the guard and also that you are using the correct type of cutting disc. For tips on how to use an angle grinder see our project here.

If you only have a very few small cuts to make then using an angle grinder and correct disc is probably the best way to go, however if you have a fair few cuts to make then the best tool to go for is the stone saw of cut-off saw mentioned below.

- Measure the exact size of the cut you need to make using a tape measure and then mark these dimensions on the paver, block or slab to be cut using chalk, a decent marking pen or a thick pencil

- Place the item to be cut on a flat and level surface on a bed of sand. The sand is important as during cutting, the vibrations created by the saw can easily crack slabs and similar items. The bed of sand helps to absorb these vibrations and reduce the risks of damage

- Cutting a straight line with a saw or grinder can be a tricky job as the disc is constantly biting and catching and can easily run off course. To keep it straight and true it’s best to use a straight edge guide such as a piece of angle steel or a spirit level. Using some shallow clamps, clamp the straight edge in place along the cutting line ensuring that the ends of the clamps are sat nicely on the sand bedding. In this instance as we have done this many times we are able to cut a straight line without using a straight edge

- Connect a decent vacuum hose to the connector on the cutting guard and turn the vacuum on

- Place the cutting disc over the cutting line and start the grinder up. Lower the cutting disc down until it touches the slab and starts to cut. Keep a strong hold of it as it will bite as it catches. Cut along the cutting line a cut 5mm or so deep to create a score

- Move back to the start and this time cut deeper into the slab. As you cut angle the cutting disc around 15° out so that the disc cuts into the slab creating a slight overhang. This is to prevent any jagged edges causing issues and tight spots when fitting

- Continue with your passes until you have cut through the depth of the slab and the waste piece falls away

Slab to be cut marked out

Slab placed on bed of sand to reduce risks of vibration damage

Cutting line scored on slab

Slab cut using an angle grinder

In some cases it may not be necessary to cut all the way through the slab. As we mentioned above creating a shallow weakness can be just enough to allow the slab to break when given a few good taps with a rubber mallet so it’s well worth stopping and testing

Using a Stone Saw or Hand-Held Cut-off Saw to Cut Slabs and Pavers

The steps used to cut a slab using a stone saw, petrol cut-off saw or hand-held cut-off saw as they are known are pretty similar to those mentioned above however in this case a water-based dust suppression system is used.

If you have never used a tool like this before then check out our project here that details everything you need to know about how to use a cut-off saw.

- Firstly measure out the size of gap that needs filling and then use a piece of chalk, pencil or decent marker to mark the dimensions on your slab

- Locate a flat and level surface and then lay a bed of sand roughly 2-3 inches thick. Flatten it out to create a nice surface for your slab to lay on. Laying it on a bed of sand whilst cutting will reduce the vibrations from the saw that will be transferred through it that can easily break it

- If you have never used a petrol cut-off saw before the best route to take is to add a straight edge along side your cutting line so that you have am edge to follow and ensure your cut is straight and true. Using some shallow clamps, clamp a spirit level or better still a piece of angle steel along your cutting line and lay the slab back down flat and level on the bed of sand

- Position the saw near to the cutting site. Fill up your dust suppression water bottle and connect the hose end to the water suppression system point on the side of the saw. Once connected pump the handle on top the bottle to build up some pressure. Once up to pressure you should then start to see water pouring from the spray points above the cutting disc

- Once the water is pouring start up the saw. Position the cutting blade above your cutting line and then rev the saw up to speed and lower the disc down on to the line. Run the saw along your cut line to create a first pass cut and guide to follow

- Once the first cut has been made, move back to the beginning and then repeat the cut again, this time cutting down through the slab. As you cut, cut down at a slight angle of around 15° back into the slab to create a slight overhang. This will ensure no rough edges are left that can affect the fit. Once cut all the way through the waste section will fall away

Slab marked out for cutting

Slab to be cut laying on bed of sand

Water suppression system connected to cut-off saw and pumped up to pressure

First pass cut made to slab

Slab cut to required size using a petrol cut-off saw and laid in place

As you are cutting keep an eye on the flow of water from the surpression system and ensure that it is damping down any dust that is created. If it starts to reduce in flow rate, pump the handle on the bottle to build the pressure back up.

Using a Block or Slab Splitter

If you have a large amount of block pavers or slabs to cut that need cutting accurately or are working in an area where the possibility of creating any dust is an absolute no no then the tool to use for your slab and paver cutting needs is the block and slab splitter

Available in two different types; manual and hydraulic, the manual slab splitter utilises a handle that drives a cutting blade down to split the brick, block or slab and hydraulic that utilises a hydraulic ram to do the cutting.

In general, manual splitters are good for most standard sizes of block or slab but as hydraulic splitters can except huge amounts of pressure down they are more suited to larger, thicker and denser blocks and slabs.

On the majority of models the cutting blades can be widened or closed up depending on the size of object being cut by turning a screw mechanism.

- Firstly measure and mark your exact cutting point on the brick, block or slab to be cut. Use a piece of chalk, marker or decent pencil to make your mark

- Lift the handle of the splitter all the way up to open the jaws fully. The handle should come to a natural rest point at its peak that will hold the jaws fully open. Also ensure the splitters handle is fully extended to give full leverage and cutting force

- Take you brick, block or slab and position it on the cutting bed of the splitter and then wind the jaws down so that they just hover above the object but don’t touch it. This will also give you the maximum amount of down force for cutting

- Align the cutting line on your object with the cutting blade of the splitter ensuring that the object is directly below the blade. Again this will help focus all the cutting force down on the correct point. Also if its slightly off this can often result in a failed cut

- Once positioned, pull the lever down so that the blade drops onto the cutting line and apply consistent pressure to the handle driving the blade down through the brick or slab being cut. Don’t jerk it, just keep a constant down force on it until it splits through

- Once cut its common for each piece to fly apart with some force but make sure the section you actually want to use doesn’t fall on a hard surface and crack with can happen. Top prevent issues such as these place some old sheets or mats below the cutter to catch any escapees

Whether you are cutting bricks, block, paving slabs or large flagstones each of the above tools and methods can be used to great effect but the tool or method that’s best for you e.g. using a angle grinder, cut-off saw, splitter or a good old hammer and bolster will ultimately depend on the finish you need, where you are working to and also the speed that any cuts need to be made at.