We often receive questions about plastic or UPVC conservatories, particularly building them yourself.

To ensure your DIY conservatory project is successful, start by accurately measuring the space where the conservatory will go. Incorrect measurements can lead to fitting issues and may void the 10-year guarantee on most conservatory parts. Additionally, any modifications you make could also invalidate the warranty.

As most DIY conservatories differ slightly in their construction, in the below guide we run through the general principles of how they are built.

Popular DIY Conservatory Designs

After choosing and measuring your installation area, you’ll need to decide on a design for your conservatory. Here are some popular styles:

Edwardian Style Conservatory

Victorian Style Conservatory

Lean-to Style Conservatory

Gable Style Conservatory

Most DIY conservatories are modular, meaning they consist of standard-sized parts that fit together to create a pre-defined shape. Some modular parts, like French doors, can be repositioned within the frame, depending on the manufacturer.

Key Features for Your DIY Conservatory

Choosing the right features for your DIY conservatory depends on its intended use. For daily use, such as a study, opt for energy-efficient glazing and roofing to minimise heat loss. For occasional use, like a dining room, heating efficiency may be less critical.

Regardless of use, ensure your DIY conservatory meets these minimum specifications:

- 28mm Thick Toughened Low-E Glazing – Essential for heat conservation, this glazing reflects heat back into the room, reducing heating costs. Consider brands like SGG Planitherm or Pilkington K.

- 25/35mm Thick Polycarbonate Roofing – Provides good thermal insulation and is cost-effective.

- Glass Roofing – A high-performance alternative to polycarbonate, with self-cleaning options available.

- Opening Fanlights with Shootbolt Locking – Allows ventilation in a well-insulated conservatory, crucial during summer.

- 70mm Internally Beaded Double Glazed Frames – Offers better energy efficiency and security compared to 60 or 65mm frames.

- Complete Fitting Kit and Instructions – Ensure you have all necessary fixings and clear instructions for a successful DIY build.

DIY Conservatory Planning Permission

Before building your DIY conservatory, you may need to apply for planning permission. Navigating these requirements can be tricky, so here are some key guidelines (note that these are for reference only and not legal advice):

- Ensure that no more than 50% of your property’s land is covered by additions.

- If your property faces a highway, the conservatory must not extend beyond the principal or side elevation.

- The conservatory can extend up to 3 meters for semi-detached homes and 4 meters for detached homes.

- For detailed and current regulations on conservatory construction, visit the Conservatories Planning Permission section of the Planning Portal website.

Choosing the Right Base for Your DIY Conservatory

Installing a conservatory is straightforward with basic DIY skills and patience. Most DIY conservatory kits come with clear instructions to guide you. Your first step is to build the base, and you have two main options:

- Opt for a traditional concrete base

- Install a pre-fabricated base system

Concrete Base for a Conservatory

A concrete base is a time-tested method for conservatory installation. You start by laying a level base and then build your conservatory on top. After setting the base, you can choose between two options:

- Build a dwarf wall and then place the conservatory on top of it.

- Directly install the conservatory frames onto the base for a full-height conservatory.

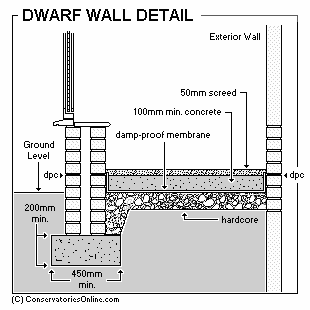

Dwarf Wall Detail

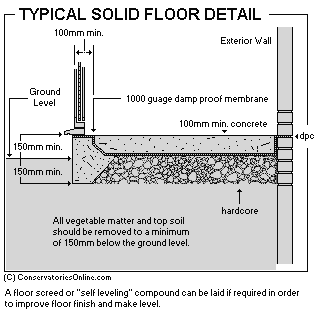

Solid Floor Detail

Each option has its pros and cons:

- Advantages: Pouring concrete and building a wall are manageable DIY tasks, or you can hire a builder. Using matching bricks or blocks for the dwarf wall enhances aesthetics and insulation.

- Disadvantages: The quality and cost of builders can vary, and the process can be disruptive with the need for skips, concrete lorries, and building materials.

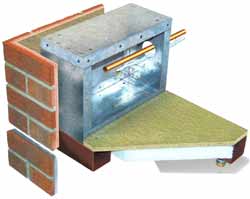

Pre-fabricated Base

Also known as "Steel Bases", pre-fabricated bases are a modern and increasingly popular choice for DIY enthusiasts. This option allows you to complete the installation without a builder’s help.

Pre-Fabricated Conservatory Base

Pre-fabricated bases consist of galvanised steel sections for the base and walls, which are covered with "brick effect tiles" bonded to the steel. This design prevents rust and corrosion.

- Advantages: Quick and easy to install with minimal disruption, making them ideal for areas with limited access. Many include built-in service channels for cables and utilities.

- Disadvantages: Limited to standard brick designs, which may not match all property styles. Also, they generally offer less insulation compared to traditional brick walls and bases.

Conservatory Installation

Building your conservatory yourself is the most cost-effective option. With a DIY conservatory kit that includes detailed instructions, and if you have the right skills, you’ll find the process straightforward.

Many companies let you design your conservatory and then build it to your specifications. Be sure to keep a copy of the design drawings for your reference.

While your kit will come with comprehensive instructions, here’s a brief overview of the basic installation steps:

Step 1 – Check Area Fully

Ensure the area for your conservatory is free of debris and tree roots, which could later crack the floor slab or damage your base.

If you’re hiring a builder, having them clear the site and lay the base or dwarf wall will save you both time and money.

Step 2 – Lay Base

Once you’ve chosen your base type (concrete or pre-fabricated), the next step is to lay it.

The size and type of conservatory will influence the base you need. Always check with your DIY Conservatory kit manufacturer for specific requirements.

Ensure that each corner of your base is perfectly square and don’t forget to install a damp proof course if needed.

For a concrete base, a damp proof membrane should be placed below it. For dwarf walls, install a damp proof course above ground level (see images above).

For pre-fabricated bases, follow the manufacturer’s guidelines for damp proof course and membrane specifications and where they need to be installed.

Step 3 – Building Dwarf Walls (if needed)

After your base has dried, you can start constructing the dwarf walls, if they are part of your plan.

Refer to our DIY guide on laying bricks for detailed instructions.

If you need to install electrical sockets, ceiling fans, or phone lines, consider these during the construction of your dwarf walls.

Consult a qualified electrician to get advice on when and how to install these elements. They can guide you on the best stage for installation.

Step 4 – Check the Kit Over

Once you have layed your base and received your conservatory kit in full, use the drawings to check you have all the elements required.

Next, layout all the frames in the positions in which they are to be fixed to make sure you have all the items you need and also that will all fit together.

Also, very carefully check over all the components and ensure there is no damage. If there is then contact the manufacturer and they should provide replacements.

Step 5 – Start Construction

Once you have ensured that everything fits together as it should, all the components are there and that there is no damage, you can now begin construction.

All the fixings required should come included with the kit. These will in most cases be types of bolt or frame fixings. As above, check the number of fixings you have with what should be provided to ensure everything is there.

Check each opening is correct as you build e.g. check both the opening width and the height and also measure from corner to corner to ensure it’s square.

Base layed, dwarf walls constructed and side panel modules joined together

Complete side panel placed on wall and fixed in place on to dwarf wall. Front module added and fixed to dwarf wall and side module to give it some ridgidity

Front section modules added and fixed to dwarf wall and conjoining modules. Door opening frame added and fixed to base and conjoining modules

Roofing bars fixed into position

Step 6 – Fit Glass

Once you have successfully constructed all of the frame work of the conservatory, ensured everything is secured as it should be, all openings are square etc., you can then start to fit the window glass and beads as stated in the instructions.

For full details on how to do this, see our double glazing how to project.

Glazing added to side modules and roofing fixed into roof area

Step 7 – Seal Joints

The next job is to now seal any and all joints as directed by the manufacturers instructions.

This is absolutely essential and integral, as it will prevent any water and moisture ingress into the conservatory interior.

For help with how to use a sealant gun see our using a sealant gun page.

Step 8 – Time to Finish

With your DIY Conservatory now constructed in full you can decorate to your requirements.

How you decide to finish your particular build is very much up to you, but generally this stage will involve plastering dwarf walls (if you have them), or possibly painting instead, decorating any other bare walls and also adding a covering to the floor.

One other job may also be fitting blinds to allow you to both control light levels and also provide some privacy.

As the majority of the conservatory is plastic frame, there is in most cases, generally very little to actually decorate.

Building your very own DIY conservatory may seem like a huge job, way out of the abilities of most, however if you have a bit of DIY experience, some common sense and aren’t afraid of hard work, then it’s certainly more than achievable.