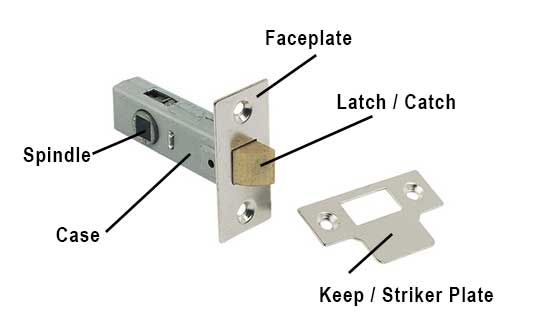

A mortice latch is the most common of door furniture being fitted to internal and external door alike. It is simply a catch that holds the door closed with a handle either side to open and close it.

To hold the door closed, the catch of the mortice lock sits in a keep that is fixed to the door frame. When the door is pushed closed, the catch engages with the keep and holds it closed.

When the handle is then turned, the catch is retracted back into the lock which disengages it from the keep and the door can then be opened.

A mortice latch or lock (or tubular latch as they are also known) is a fairly simple item to fit to door, but does require some basic carpentry knowledge in order to cut the latch and keep into the door and door frame.

Standard mortice latch or tubular latch fitted to an interior door

In most instances, a mortice latch will need to be fitted to a newly hung door. If you require additional help and advice on how to hang a door, see our project here.

What is a Mortice Latch and how Does it Work?

As we have briefly touched on above, the mortice latch or tubular door latch allows someone to shut a door and ensure that it stays shut by means of a latch engaging with a keep that is fixed to a door frame.

When the door is closed, the latch (or catch) extends from the mortice latch casing into the keep on the door frame and holds the door closed by means of a spring that is located behind the catch that applies pressure to rear of the catch, ensuring it remains extended outwards.

Mortice latch or tubular door latch showing the latch casing, the catch and door handle spindle insert

When the door needs to be opened, a door handle or sometimes a knob is turned, which in turn is attached to the latch via a door bar (or door spindle) that runs through the latch.

As the handle is turned, the spindle or bar turns in the latch that pulls the spring and catch back into the case and thus releases the catch from the keep allowing the door to be opened.

When the handle or knob is then release, the catch or latch springs back out.

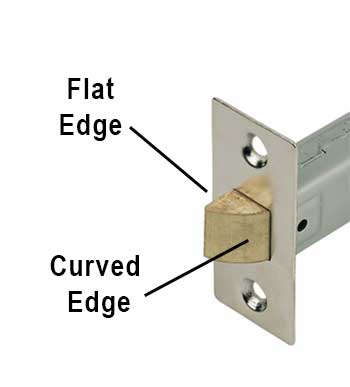

One little note on the catch itself – It’s shaped so that when it’s pushed closed the curved rear of the catch rolls over the keep smoothly allowing the door to close, but once closed the flat edge on the front of the catch prevents the door from being pulled open.

Curved and flat edge of a door latch or catch

What Different Types of Door Latch are There?

Now that we know exactly what a mortice latch or tubular door latch is and how it works, let’s take a quick look at the different types available.

On the whole, when looking at the selection of different latch’s available at your local DIY shed, apart from different sizes (we’ll get to these below) they may all look pretty much the same and you would be right to think this.

The main difference between each type of catch comes with it’s build quality and type of internals:

Budget/Economy Door Latch

As the name suggests, this type of latch is at the bottom of the pile in terms of quality, durability and longevity.

The materials used in construction of this latch are cheap e.g. cheap low grade steel and in some cases (manufacturer-dependent) feature plastic components such as a plastic keep.

At the end of the day, you get what you pay for. If budget is a major concern then this type of latch is the one to go for, but bear in mind, it won’t last!

Budget quality door latch

Middle of the Road or Standard Quality Door Latch

This type of door latch is suitable for pretty much all door closing requirements. Unlike the budget latch, the construction materials used are of a higher quality and due to this should last longer than its budget counterpart.

Although it’s a better choice than the budget option it may still lack in terms of operational smoothness and overall longevity.

Middle of the road or standard quality door latch

Dual Spring (Double Sprung) Door Latch

Now we’re getting there! The double-sprung or dual spring latch is of a much higher quality in terms of materials and also build than both the standard and budget versions and this can really be felt in its operation.

The dual sprung latch feels much smoother to use when both turning the handle to open and also when pushed closed.

The “dual spring (or double sprung)” reference refers to the fact that latch has a separate spring for the latch that allows for a very smooth closing action.

The spindle also benefits from having a much stronger spring. This helps to make sure that handles and knobs are always returned to the centre and are not left drooping if the handle spring is a little weak.

Dual spring or double sprung door latch

Top Quality Heavy Spring Door Latch

This is about as good as it gets! The heavy sprung door latch is the daddy of the latch world and features pretty much all of the top quality materials and construction techniques used in the dual spring latch (sometimes even better) but also benefits from having an even stronger return spring.

The improved return spring has several benefits in terms of an even smoother closing action plus the fact that it’s “pushing” strength ensures that both handles and knobs are always returned to a central, horizontal position, even those handles that do not themselves feature a return spring.

Top quality heavy spring door latch

What Sizes of Door Latches are There?

If you are new to the world of fitting door latches then knowing what size latches are available and when to use them is fairly essential.

In the Uk there are really only two main sizes to be aware of:

- 63mm or 2 1/2 inches

- 76mm or 3 inches

As with most things there are other size variations available such as 102mm, 127mm and 152mm but these tend to only be used in certain, less common situations.

If you are simply replacing a broken door latch with a new one then it’s best to replace on a like-for-like basis e.g. replace the old one with a new one of the same size. In the majority of cases you will probably have a 63mm door latch.

As these are slightly cheaper than the 76mm versions they are the preferred choice of tradesmen and larger construction companies where budgets are a strong consideration.

If however you are starting from scratch then it’s a good idea to use the 76mm version as this tends to result in a slightly better finish due to the fact the door handle sits in from the edge of the door a little further and is a little more centrally aligned on the door stile.

If you are going to use door knobs instead of handles then the 76mm door latch is pretty much the minimum you should use (ideally you should go for the 102mm). This is to ensure that the knob sits back far enough on the door to avoid anyone catching their knuckles on the door frame when they turn the knob.

Door knob fitted using 76mm latch to ensure knob located further in from the edge of the door

One point to note is that the measurements stated above (63mm, 76mm etc) are the measurements of the case size of the latch and are taken from the faceplate to the end of the case – more on this below.

To some degree the size of the lock block within your door may dictate the size of latch that you can use due to how far it extends into the door, but in the majority of cases there shouldn’t be any issues regardless of the size of latch you go for.

How to Measure a Latch

Now that we have looked at the different sizes of door latch available it’s time to look at how these measurements are actually calculated.

If you are replacing a door latch the simplest and best method to determine what size of latch you should purchase is to remove the existing one and measure it. Once you know the size you can then purchase and exact replacement.

Once the existing lock has been removed, measure from the back of the faceplate to the opposing edge of the case

Measuring from the faceplate to the edge of the case to determine the size of an existing door latch

With your measurement now taken, pop down to your local DIY shed and purchase an exact replacement. To ensure it’s the right one, check on the packaging and it should state the “case size”.

One other very important measurement to be aware of is the backset size. This measurement refers to the distance from the rear of the faceplate to the centre of the spindle hole in the latch (the hole the handle spindle goes through).

If replacing an existing door latch with new make sure your new latch has the exact same backset as your new latch as you don’t want to have to start drilling new spindle holes in your door as you could run the risk of your old hole becoming visible if the casing of the handle doesn’t cover it fully.

Measuring backset size of door latch

How to Fit a Mortice Latch to a Door

Now that we have looked at all the different sizes and types of door latch and how to correctly measure a door latch, it’s time to look at how to actually fit a door latch to a door.

Mark Position of Door Latch and Spindle Hole on Door

The first job is to mark the position of where the latch is going to sit on the door, but before you start marking away, make sure that you are marking the correct edge of the door.

If you are fitting a brand new door (see the link at the top of this page for how to hang a door if you need help with this) then you need to be aware that one side is meant for the hinges and the opposing side for the latch and handles.

To identify which side of the door this is at one side of the top of the door it should be stamped with “Lock Block”. This states the side of the door that the latch should be fitted to.

Lock block stamp on door to signify side that door latch should be fitted to

Now that we know the correct side of the door that the latch should be fitted to, we can now start marking up.

Position the door latch on the edge of the door so that the faceplate sits around 1mm in from the front edge. This is to compensate for the fact that the latch will be cut in or recessed into the edge of the door so that the outer side of the faceplate sits flush with the doors edge.

Additionally, ensure that the latch is as central to the doors lock rail as possible (the horizontal mid section of the door).

With the latch in position, mark the top and bottom edges of the faceplate on the door using a pencil and then mark the centre of the spindle hole on the door, again using a pencil.

Once marked up, remove the latch and draw a level line across the edge of the door to signify the area that needs to be chiseled away for the latch to recess in nicely.

Top and bottom edges of latch marked along with the spindle hole

Next, position the faceplate with the top edge flat on the face of the edge of the door in the centre of the edge. In the majority of cases, the faceplate will be the full with of the timber that makes up the edge of the door, but this will ultimately depend on the type of door.

As you can see in the image below this was indeed the case (bar a mm) so we were okay to cut the latch in the full width of the timber without it looking untidy or gappy.

If this is not the case for your door, you will need to measure and mark the size of the face plate in the centre of the timber so that the latch fits precisely without any gaps.

Chisel out Recess for Latch

With everything marked out, it’s now time to chisel away roughly 1mm of timber so that the faceplate can sit nicely down into the edge of the door and avoid fouling on the door frame when it’s closed.

Using a decent sharp chisel and hammer, lightly tap the chisel so that it bites down into the timber.

Hold the chisel so that the angled/beveled face is flat with the edge of the door when chiseling. work your way down leaving roughly a 5mm gap between chisel marks until you reach the bottom mark.

Now use the chisel to remove the timber, pushing gently or tapping with the heel of your hand. It’s advisable not to use the hammer for this as you can easily chop down too far into the timber.

Once the bulk of the timber has been removed, use the chisel to remove any raised sections until you are left with a nice flat and level base.

Chiselling out recess for latch faceplate to fit into

Drill out Hole for Door Latch Case

With the faceplate recess now cut, the next job is to drill out the hole for the latch case to sit in. It is possible to do this before chopping out the recess but can make cutting the recess a little trickier.

Before any drilling you will need to mark out the position of the latch case hole.

Measure the full height of the latch faceplate and then divide this number by 2. This should then give you the centre of the faceplate and the case should (in most cases) by located at the centre of the face plate.

To check, hold the latch side-on and measure down the measurement you arrived at above from the top of the faceplate. If all is well this should be pretty much bang on the centre of the case.

However, if not, with the latch held side-on, measure down from the top of the faceplate to the centre of the case and this is the measurement you will need to use.

Moving back to the door, measure down from the top of the recess the above measurement and mark this position. Next, measure the width of the door and then adjust the mark so that it is at the correct distance from the top of the recess but also dead centre. This is where you latch case hole is going to be drilled.

To drill out a door latch case hole, the best tools to use are cordless drill/driver and a suitable sized flat drill bit or auger drill bit.

To select the correct sized bit, measure the width and height of the latch casing (should be roughly square and around 20-25mm per side) and select a bit that’s slightly larger e.g. if the casing measures 25mm x 25mm use a 28-30mm bit.

As the hole you are drilling is going to be circular, but the casing is square (can in some cases also be circular – if so, allow 1-2mm either side) you will need a little wiggle room to allow the casing to fit.

As we have stated, go a little larger but not too big! You don’t want to remove too much of the lock edge of the door to compromise any strength or even cut the actual sides of the door away so check your chosen width bit against the width of the door edge.

One final point is to measure the depth of the latch casing (in this case 63mm) and add on 3mm or so and then measure this from the point of the drill bit back up this shaft and then wrap some tape around this point.

This will signify the depth that you can then drill into the door before needing to stop.

To drill the hole, position the centre of the bit directly on the point you marked earlier and drill down into the door. Make sure that you hold the drill both horizontally and vertically level at all times so that your hole is straight and level.

Once you reach the required depth, stop and retract the drill and then clean out the hole using a vacuum to remove any dust and shavings.

With the hole drilled now do a test fit of the latch.

You may find that it’s either very tight or won’t go into the hole at all. If so, you will need to use a small chisel to chisel out the sides of the hole to square it up slightly.

Squaring up circular hole to fit square door latch

This is a bit of a trial and error job so work slowly and test fit the latch regularly until it can be pushed in and pulled out easily.

Latch recess and case hole drilled and chiseled in edge of door ready for fitting

Drill Hole Through Door for Spindle

With the latch hole drilled out, the next job is to drill out the spindle hole.

As with the latch, measure the sides of the spindle (should be around 7-8mm) and then select a drill bit that’s a few mm bigger e.g. if spindle is 8mm per side, select a 13mm flat drill bit.

This is allow enough room for the spindle to turn in the hole when the handle is turned and prevent it binding on the door that will then in turn cause it to stick.

Position the centre of the drill bit on the point that you previously marked and start drilling.

As before, hold the drill both horizontally and vertically dead level to ensure not only that your first hole is level, but when the bit passes through the first door panel and starts drilling into the second on the opposite side of the door, that both holes then line up.

On this point, as soon as the drill bit starts on the opposing door panel, stop drilling as soon as the centre point starts to break through.

Once it does, move around to the opposite side and drill in from this side.

If you kept on drilling from the opposing side, when the flat part of the drill bit breaks through, in most cases this will cause break out or burst out e.g. the edges of the hole burst outwards and this can cause a fair amount of damage!

Door handle spindle drilled through door

Once the spindle holes have been drilled, insert the latch to make sure the holes line up nicely

Door latch and spindle holes lining up nicely

Countersink Latch Screw Holes and fit Latch

In order for the latch to fit snugly in the recess it’s necessary to drill out some countersink holes in the edge of the door so that the screw countersinks in the latch can be sunk, resulting in the latch sitting in flush with the doors edge.

Position the latch back into the door and push it in so that’s it’s flat to the door beneath it. Using a pencil, mark each screw hole on the timber below and then remove the latch.

Using a suitable size pilot drill, drill out a pilot hole for each screw and then swap the drill bit for a countersink bit and drill out a countersink for each screw hole (for help and advice on pilot holes and countersinking, see our project here).

Once done, pop the latch back in to make sure that it pushes down in and fits flush to the face of the door. If not, remove it and drill out the countersink holes a little more until it does.

Once fitting nicely, screw in a screw to each hole on the face of the latch to secure it in place.

Door latch screwed up firmly on to door

Fit Door Handles

With the latch securely fitted to the door, it’s now time to get the handles fitted.

Pick one side of the door to start on – either side is fine.

Pop the spindle/door bar through the spindle holes so that it is roughly centrally aligned and then push a handle over it. Make sure that you select the right handle as each one is specific to each side of the door e.g. when pushed downwards it should pull the latch in.

With the handle fitted in place, hold a spirit level along one edge and turn the handle until it is both horizontally and vertically level.

Using a spirit level to level up the door handle

Once leveled, use a pencil to mark through each screw fixing hole onto the door beneath and then remove the handle and put it to one side.

Marking screw fixing holes for door handle

Uisng the correct size pilot drill, drill out each screw hole and then pop the handle back in place and insert each screw one at a time until the handle is fully secured to the door.

With the first handle completed, repeat the above for the other handle.

One thing to be aware of in terms of the spindle is that if it’s a brand new one, you may need to cut it to length as when bought new they are of a standard size to fit any type of door. To cut them, you can simply use a hacksaw.

Once the other handle is firmly fixed into position give it a couple of turns to make sure that all operates as it should and that it pulls the latch/catch in fully.

Fit Latch Keep/Striker Plate on Door Frame

With the latch and handles now fixed in place on the door, the final job is to fit the keep or striker plate on the door frame so that when the door is closed it is held shut.

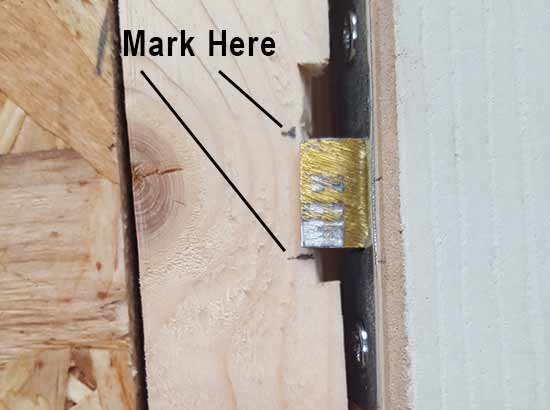

The first job is to push the door closed until the catch touches the frame. Don’t close the door fully.

With the catch touching the frame, put a pencil mark above and below it on the frame. This is to identify the exact point on the frame that the keep needs to go.

Door pushed closed so that latch position can be marked on door frame

Next, we need to work out how far back into the frame the keep needs to be located to ensure that the door closes flush with the frame and is held tight against the door stop without any rattling.

Using a ruler or tape measure, hold the end of the tape or rule against the flat edge of the catch and measure the distance from the catch to the edge of the door.

Measuring the distance of the latch from the edge of the door so that measurement can be transferred to door frame

At the point that you made the catch location marks on the door frame previously, measure in from the edge of the frame towards is centre at both mark points the measurement taken above and then draw a vertical line between these two marks.

This line will now dictate where the catch section of the keep needs to go to ensure that the door closes flush.

Pencil line to set the location of the keep on the door frame

How that we have our catch location and depth marked on the frame, take the keep and position it on the frame so that the catch hole in its centre is aligned with the catch marks on the frame.

Once positioned, move the keep until the catch edge is aligned with the vertical line you drew above.

When everything is lined up correctly, use a pencil to draw around the edge of the keep.

Marking the edge of the lock keep on the door frame

Using your chisel as you did above to chop out the faceplate recess, now chop out the keep recess, chopping out about 1mm depth.

Once done, put the keep back on the frame to test fit. If all is well and good, use the chisel to tidy up the recess, making sure you have a nice flat base.

Test fitting the keep on the door frame

When all is tidy, put the keep back in place and mark around the centre catch area and also mark the two screw fixing holes.

Using a suitable pilot drill, drill out the fixing hole sand then counter sink them.

Finally, use the correct size flat bit or auger drill bit to drill out the catch area, drilling down to roughly 10-15mm. You can then use a small chisel to square up the hole.

Pop the keep back in place and then screw in the two screws to hold the keep firm to the frame.

Now that the latch is fixed to the door and the keep is fixed to the frame, the final job is to make sure everything closes as it should, so shut the door and ensure the catch engages fully and when you turn the handle to open the door there’s no binding with the catch on the keep.

Door closed and latch successfully engaged with keep fixed to door frame

Congratulations, you have now successfully fitted a door latch or mortice latch and keep to a door.