There are a huge number of different types of roof truss in use in construction today and depending on the type of roof that you have on your property will depend on the type of roof truss used to construct it.

In the project below you will learn about the most common types of roof truss including how they fail and how they can then be repaired.

What is a Roof Truss?

Roof trusses are frames made up of timber that is nailed, bolted or pegged together to form structurally interdependent shapes of great strength. Never remove, modify or cut into a roof truss without consulting a Structural Engineer: your roof could fall down!

Roof trusses have to withstand the weight of the roof timbers and coverings (the ‘Dead Load’), plus a factor for your local Wind Load, a factor for your local Snow Load and an additional Safety Factor.

A Structural Engineer would be in charge of calculating these figures and ensuring that the right roof truss is used for the property it’s being installed on and its location.

If you need to modify or repair your roof and trusses you would need to employ the services of a structural engineer and no work of this nature should be done without one!

Roof trusses come in all shapes and sizes to suit almost every single design of roof. If you cannot find the truss you need below you may need to find a good carpenter to build a traditional ‘cut’ roof.

This means that your roof is made up from timbers on site. If your existing roof trusses are damaged in any way it is possible to repair them without taking your roof to pieces.

Types of Roof Trusses Available

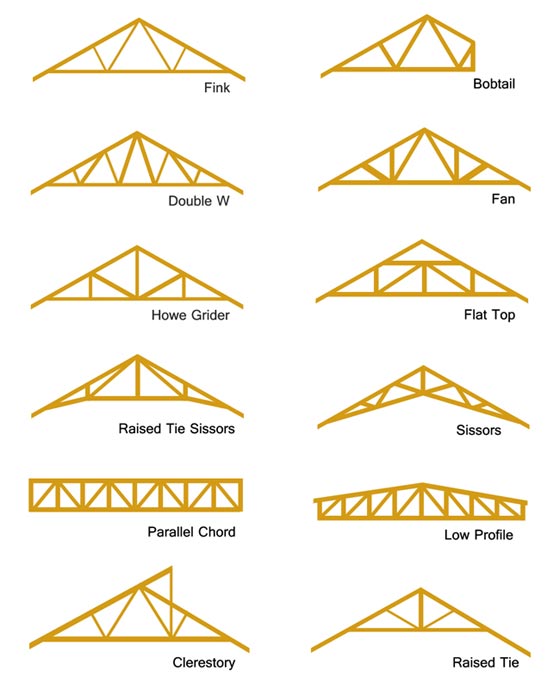

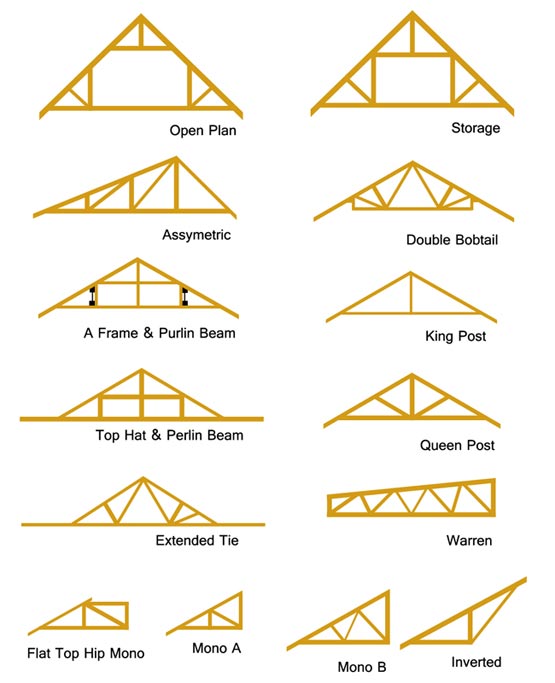

Below you will find a selection of the most common types of roof truss design and what they are called:

Different types of roof truss

Types of Roof Truss

What Makes a Roof Truss Stand up?

The truss depends on three main characteristics, which can be given ‘numbers’ so that a Structural Engineer can calculate a safe load;

- The strength of the timbers – modern trusses are very lightweight, so only structural kiln dried timber is used and it is usually pre-treated, to prevent insect and rot attack. You can specify the TRADA Strength Grade when you buy timber – for example, C16 or C24 – if an Engineer supplies the Design information

- The distribution of the load through the parts – the design is critical – if you take one component out, or weaken it (say by cutting notches for pipes) it will be seriously weakened

- The connection of the parts – the bolts, plates, screws, glue or pegs that hold it all together. These must not be cut or changed without professional advice

Timber-Resin Splice Repair Kits for roof trusses available from Property Repair Systems

What Causes Roof Truss Failure?

The biggest enemy of roof structures (apart from the notch cutting or hole drilling by an electrician or plumber) is Water.

- Penetrating damp – water leaks – these lead to rot and insect attack, even in treated timber, which is not always treated all the way through its thickness. Older buildings are most susceptible, especially where the rafters or tie beams sit on, or in the walls. Conditioning using a top quality wood treatment or preservative is essential if dampness has affected the wood to prevent any further damage

- Rot and Insect Attack – usually associated with dampness, but mainly in older, pre-Second World war properties, where solid, non-cavity walls or thick random stone walls support the bearing ends of the rafters and/or tie beams. Traditionally, the ends of the timber were treated with bitumen but today quality wood treatments can be used to stop the rot and insects from destroying the roof’s structural bearings. These potentially damp areas require careful inspection with a torch and prodding with a screwdriver. Drilling with a small diameter Auger is advised, if you have any doubt about the strength of a component.

- Joint Failure – modern roof structures mostly use ‘nail plates’ or plywood plates fixed with nails, screws and glue. Older roof timbers were connected with Mortise and Tenon joints, plus wooden pegs. These tend to be eaten away by woodworm and the roof beams then move, opening up the joints. Resin Repair, with Tie Bars and injected resin, can solve this problem

How to Repair Roof Trusses

If you have found that you have damaged roof trusses, joists or rafters then this can be a big problem and in turn cause knock on effects such as sagging ceilings, sagging roofs, additional load stress on other areas, transference of the cause of the damage into other materials e.g. woodworm can travel from one set of timbers to another or damp and dry rot can affect adjoining timbers etc.

Before any repairs are made it is essential that, firstly, the cause of damage is identified and fixed as you don’t want to go to the hassle and cost of repairing the damage just for it to come back in the future because the root cause was not sorted.

Check all areas around the damaged area e.g. roof tiles, brickwork, mortar joints and pointing, chimney stack, water storage tanks, timber and woodwork (woodworm or infestation), plumbing/heating system and pipework and anything else that may be unique to your property until you establish the cause.

Once this has been cured you can then look at getting the damaged timber(s) sorted. In most cases you have three options:

- Removal and replacement of entire truss if it is beyond repair

- Repair using timber resin splice

- Repair using joist end repair plates

Replacing an Entire Roof Truss

This is obviously in the worst case scenario if the timbers are so badly damaged that there is no chance of repairing them and the only choice left is to remove all damaged trusses and replace with new ones.

The costs and in turn the hassle involved can be massive as most of if not all of the roof will have to come off so that suitable access can be gained for removal and replacement to take place. In most cases a crane or suitable lifting equipment will be needed to hoist the new truss in.

In some instances it is possible to remove the truss internally from within the loft space and then rebuilt but this depends on the type of truss and also the type of roof construction.

Badly rotten timbers

Timber Resin Repairs for Roof Trusses

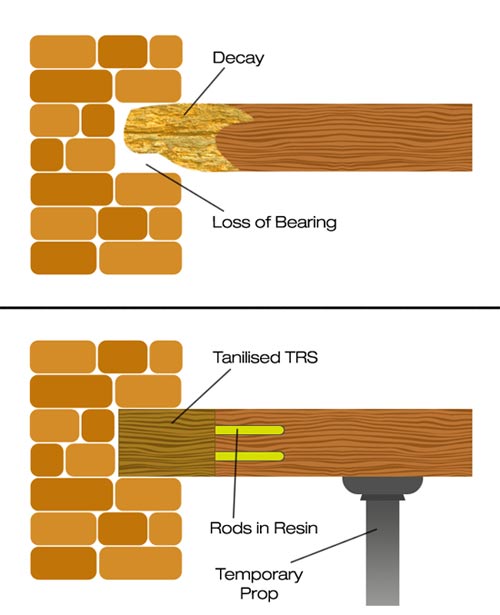

There is always the possibility in older properties that your rafters, joists or trusses may have dropped at one end because over time the timber has become rotten and compressed due to long term exposure to damp.

Thanks to some incredible, yet simple technology aka the timber-resin splice kit it is now possible to replace sections of joists and rafters, in-situ. Take a look at the images below to see how this works.

Repairing joists in-situ with timber resin splice kit

As mentioned, traditionally in this situation it would be necessary to try and remove the entire damaged truss, joist or rafter and replace it with a new one.

As you can imagine this is certainly not a small job and can involve considerable cost and hassle especially if you have several damaged joists.

In extreme situations, previously it may have been necessary and easier to remove the entire roof to replace these timbers.

With the introduction and development of systems such as the timber resin splice kit much of this hassle and stress can be removed and a repair can be implemented much more easily. The basis of the repair process is as follows:

- Damaged timbers are identified and assessed and a decision is made as to whether they are repairable

- Joist, rafter or truss is examined in more detail to determine the extent of the damage and the point along the length of the timber is identified where it is stable enough for the splice to be applied

- Suitable props are put in place along the timber to support it during the repair and to take the load of the floor above and/or weight of the roof

- The top side of the joist or truss will need to be accessed so loft boarding or floor boards will need to be removed

- Damaged section of timber is cut and removed leaving only healthy timber

- New timber section is prepared by first accurately measuring what’s needed and then cutting a suitable length. Next drill the required number of holes into the front face end of the timber along it’s length and high tensile threaded steel bars are inserted and bonded in

- The existing timber section will now need to be prepped to take the new section. To do this you will need to cut a slot into the existing truss, rafter or joist in a "U" shape to the required length of the threaded steel bars in the new section of timber

- The new section of timber is now put in place with the threaded steel bars sitting in the slot. If all faces meet flat then they are bonded together

- Now mix the resin as directed on the packaging by the manufacturer until it is smooth

- Pour the resin into the slot in the existing timber until you have filled the space to the very top. In most cases the resin will self level itself

- Leave the resin to harden as directed by the manufacturer

- Once set you can then remove the supporting props and replace any floor boards or loft boards etc.

- If you have several timbers that need repairing, each repair should be carried out one at a time.

New joist or truss section with threaded steel bars inserted and bonded

Slot cut out in existing timber

Pouring resin into slot in timber

Hardened resin in slots in timber

Joist End Repair Plates for Roof Trusses

This method is not too dissimilar to using the method above. It involves cutting away the damaged end and replacing with a new piece but this time the two sections are joined using galvanised steel plates.

The basics of the process are as follows:

- Inspect and assess the damaged section of timber and determine where it needs to be cut to

- Prop the timber along it’s length using suitably sturdy props such as acro props

- Once supported, cut off the damaged end leaving only solid un-damaged timber

- Now, measure and cut a replacement piece of timber. This has to be the same size in width and depth as the old e.g. if the old timber is 8 x 4 inches then that is what you will need to use

- Next, sit the new timber into the repair plate(s). Depending on the manufacturer will depend on the types of plates you have. Some will be a "U" shape and some will be two "L" shape sections. Ensure that the timber is pushed flat against the base of the plate unit or plate sections and then screw into place using coach screws

- Position the new timber with fixed repair plates into place with the non-plate end sitting in or on top of the wall depending on how the original was and ensure that the plate end sits over the original timber and that they are butted together firmly

- Before screwing the plate to the existing timber it might be a good idea to get another prop and position it under the plate and push it firmly against the base of the original timber

- With both timbers joined securely in position you can now slowly release and remove the props

- NOTE: Make sure that you check you have the correct end plates by following the manufacturers guidelines. It is essential the plates themselves are capable of supporting the weight they will be carrying!

Joist end plate fixed to new timber section

As with any repairs to structural supports or structurally integral items in your home we certainly advise that you seek advice from a qualified builder/expert in this area or structural engineer before you attempt any fixes or repairs yourself.