Damp and timber joists do not mix well. In fact damp and any kind of structural timber, be it roof trusses, floor joists, doorframes, window frames and sills make for (largely) one or more of three types of real damage.

We look closely at wet rot and its causes and effects, the lasting damage of dry rot and how insect attack from woodworm and other wood boring beetles can severely compromise the structural (and other) timbers in the home.

Damage to Timber Joists and Floors

There are three main types of timber damage and they are all caused by damp.

Timber will start to decay at above 18% moisture content (in average softwood species, like an ordinary Pine), so elimination of dampness is always going to be the primary job.

18% dampness means nearly one-fifth of the timber is damp and this can happen purely as a result of condensation, leaking roofs, rising damp and other forms of exposure to moisture.

Timber in the home should be inspected periodically to make sure it is not exposed to any of these problems.

Types of Damage to Structural Timber

Wet Rot

When an area, or section is exposed to water, taking it’s moisture content above 18%, fungus or mycelium can start to "feed" off the timber and grow into and from the wood.

There are many types of fungus that make up the wet rot category, they include Coniophora Puteana and Poria Vaillantii with Coniophora being the main culprit. The fungus feeds off the wood making it soft and spongy.

Wet rot is often first noticed when floors, especially ground-floor, floor joists become springy under foot. Possible causes of wet-rot are.

- Unpainted and untreated timber exposed to water from roof

- Condensation water arising from lack of ventilation to roof or floor timbers especially with hollow floors. Condensation can also badly effect window sills, when condensation moisture is allowed to collect on window surfaces and run down and collect on a sills surface

- Water accumulating and being soaked up by timbers from leaking pipes, leaking wastes (bath or sink), hoses from washing machines and dishwashers etc.

- Rising damp making floor slabs and/or walls wet which in turn can affect the backs of skirting boards and door frames where no paint is usually applied

For more information on identification of wet rot, how it is caused and the remedies for it, go to our project page.

Dry Rot

Starting in a wet area of the timber, dry rot or Serpula Lacrymans is another fungus which literally sucks the life out of timber.

Unlike wet rot however, when dry rot has consumed all the moisture from one damp area of timber, it searches out another and travels over all manner of surfaces to get to it.

This way it can destroy whole properties if it’s journey remains undetected.

The causes of the damp which attracts dry rot can be the same as wet rot but the spores of the dry rot fungus germinate and then spread in very fine, almost cob-web like strands.

These strands can travel across wood, plaster, brick and any surface where they can get a hold in their search for new damp patches of timber.

Ways to identify dry rot include:

- Large mushroom type growths on the timber surface

- Large, deep (mostly square shaped) cracks in the timber surface and cubing of timber

- Orange colour spots or spores around the mushrooms or any other growth appearing on the timber

- Strings which look like a very dense cobweb running across surfaces.

For more information on dry rot, go to our information on dry rot identification, causes and remedies.

Insect Attack

Damp can attract woodworm beetles such as the Death Watch Beetle (Xestobium Rufovillosum) and woodboring Weevils (Pentarthrum Huttoni and Euophryum Confine) at the most extreme degree.

In fact, the woodboring weevil will generally be found in timber where fungus has started to take root. The causes of the damp can still be the same but the insect attack will be fairly local. Most wood boring insects prefer timber with a fairly high moisture content.

Damage from woodworm of any kind can originate either in the growing tree, where there is plenty of moisture or in the timber yard where most timber planks are stacked, very close to each other, allowing little or no ventilation and the timber gets damp through both rain and condensation.

Signs of attack from wood boring insects or woodworm are usually the emergence holes (between 1mm and 1.5mm diameter). For more information see our project on woodworm and how to identify it.

Joist damaged by damp – Wet timber invites problems from fungi and insects

Damage to brick caused by dry rot soaking up moisture as it travels across

Methods for Repairing Structural Timbers Safely

The ability to effect repairs on timber joists, beams, rafters, purlins, floorboards and all forms of structural timbers is not limited to today’s techniques.

Carpenters have been splicing timbers with special joints for hundreds of years with many of these repairs still evident today in many old buildings and indeed, ships!

To make the right choice for your repair you may need some help over and above that offered on this page. If so, then visit the PCA (Property Care Association) website here.

Firstly, look for the source of the problem before you deal with the effects.

As good as modern methods are at repair and prevention of attack from water, moisture and wood boring insects, it is tempting fate to just carry on with the repair until you have adequately diagnosed the cause of the problem.

If it is a damp problem, look for (and repair) the source of the damp.

You may need to re-roof or take a look at how your roof tiles are fixed to your roof. It may be that they are not at the correct spacing (gauge) and the rain is blowing up underneath them.

It could also be that your chimney or other flashing’s are not fitted correctly or have slipped out of their joints.

It could be that condensation is the cause and has built up because of lack of ventilation’s. This can be addressed on our pages dealing with the effects of condensation.

If leaking pipes or hoses are at fault you need to repair immediately to stop further damage to the new work you are about to do and if the damp problem has arisen because of a faulty damp proof course then this needs to be addressed urgently.

Repairing Joist Ends

The supported ends of joists can become damp because they rest inside or close to the support walls and easily absorb water from damp soil, humid air or water leaks.

This can include water traveling over the top of the brickwork through loose or broken tiles and blocked gutters. Wall plates can be affected also.

If there is little or no ventilation in the damp area, the moisture will not have the chance to evaporate and the timber will develop fungus as explained above therefore any repair or treatment must include attention to the Air Bricks or other ventilation (See our project covering air bricks and vents).

There are a number of ways to repair structural timber. The easiest way to repair joist ends is to fit joist repair plates.

These come as a pair of ″L″ shaped, metal plates complete with screws and instructions.

They have the advantage that joists are extended back into or onto the original bearing.

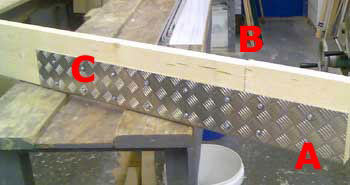

A pair of joist repair plates

Joist repair plates are bolted to the sides of damaged joists

Joist repair plates fixed to timbers

How to Position, Fix and Align Joist Plates

The best way to repair the end of a joist is to remove the damp or affected end after the floor or ceiling has been propped up as one would if removing or forming an opening through a load-bearing wall, with Acrow Props.

A new piece of timber is cut (A) to replace the damaged piece and the joists plates are positioned ether side of the joists with the end of the joist plate right up against the edge of the timber so it is the joist plate that sits on the bearer (A).

The joist plate is bolted to the timber making the joint (B) as strong as the original joist. The length of the joist plate on the original side of the joist (C) is usually at least twice that of the piece that replaces the damaged section (A).

Treating Joist Ends

As well as a joist plate, the end grain cut (A) and the support area should be thoroughly treated using good quality timber treatment and a piece of damp proofing material, such as DPC plastic should then be placed underneath, to prevent damp from finding its way from the wall into your new timber. Use pre-treated timber if possible.

Providing Enough Air Flow to Prevent Damp

Most properties will feature air bricks – these allow the flow of air either in roof spaces or under suspended floors and prevent the build-up damp and moisture.

When it comes to air bricks on the outside wall of your property you should ensure that there is at least one brick per 2.25 meters of outside wall length.

You will also have to ensure that any outside ground is significantly below any air bricks as if not, this may restrict air flow and damp issues may result.

To these ends, ensure that air bricks are clear from soil build-up, pathways or tarmac and other obstructions.

Repairing Carrier Beams and Support Beams

Carrier or support beams are normally larger timbers than joists and in respect to this, it might not be possible to use the joist repair plate system previously mentioned.

Carrier and support beams are usually (these days) installed as steel RSJ’s but in older properties or barn conversions these may well be existing timbers or indeed new, very large timbers, to maintain the integrity of the building and also to maintain it’s traditional aesthetic look.

There may also be certain conservation rules that stipulate that any repairs should maintain an existing look.

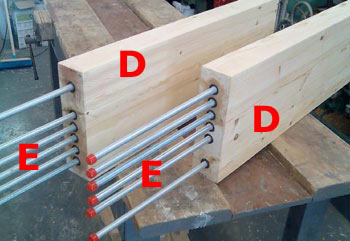

If timbers are larger than 10 x 2 inches (or 250mm x 50mm) then the most suitable repair will be to use a Timber-Resin Splice.

This system normally comes in the form of a kit for easy use and provides a new piece of timber (D), with zinc plated high tensile metal bars or rods (E).

Using resin bonded bars to repair joists and rafters

These high tensile bars will be pre-bonded into one end of the timber beam, ready for you to fit using the resins provided in the kit.

The basis of this repair method involves firstly supporting the timber so that the load weight is taken off the supporting point and the weight from the above floor or roof is stable and then the damaged section of timber is cut off far enough along the length of the timber so that only undamaged timber is left.

Obviously now your timber is going to be too short to reach the original support.

To resolve this, in the length of timber that is left you will now need to cut a slot in the top of it that is slightly longer than the protruding high tensile bars in the replacement timber splice you have.

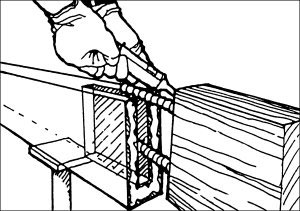

Now you can place your timber splice up to the existing timber with the high tensile bars resting in the slot that you have just cut.

Slot cut in existing timber to take steel rods in timber splice

Finally, the resin supplied with the kit is poured into the slot, bonding the high tensile bars into the existing timber. Once the resin has cured and set, the supports can be removed and the new splice section will then rest on the original supporting point creating your newly repaired timber.

Treating Carrier Beams and Wall Plates

As both wall plate timbers and carrier beams can sit on or in bricks, blocks and other similar items there is the possibility that moisture and even some fungal growth can spread from these up into the timbers causing rot, decay and even inviting wood boring insects in.

To ensure this doesn’t happen it’s essential that any such timbers are fully treated using a good quality wood treatment of preserver such as Cuprinol 5 Star Wood Treatment, Everbuild Lumberjack wood treatment or a similar quality product.

All timbers should be treated fully according to the manufacturers instructions.

When adding new timbers you should also ensure that they are pre-treated and it certainly doesn’t hurt to apply a few coats of your own wood preserver or timber treatment.