Having a decent level of light in the kitchen is an absolute necessity to enable anyone to comfortably work preparing meals and other kitchen activities.

Most kitchens only feature a single strip light or set of down lights somewhere around the centre of the ceiling which, if you also have wall units, when you’re working with your body between the light source and the object you’re preparing, creates shadows which can make it hard to see what you’re doing.

In this project we look at how you can install under unit lighting that illuminates these shadowy areas.

Regulations for Kitchen Unit Lights

As I’m sure you know, due to the dangers that electricity poses, there are very tight controls on what you can and cannot do to the electrical systems in your home.

Essentially, if something needs to be wired and installed from scratch, then this should only be done by someone with the necessary skills and knowledge to do it correctly and also test it all afterwards.

However, if the object being installed can be plugged into an existing socket or are battery powered, such as some of the options listed below, then you are fine to go ahead and fit this yourself.

Despite this, if you want to opt for something a little more integrated and permanent, such as a hard wired lighting setup, then as said, this will need to be installed by a qualified Part P registered electrician who can then issue you with a minor works certificate. Failure to do this properly can invalidate your home insurance, so beware!

For a full understanding of what your electrician will be doing when fitting lights to kitchen units, it is a good idea to read our project on light circuits to see what’s actually involved. This can also give you an indication of how much work it will be, especially if you have to do things like pull out units and work surfaces.

For further information on what you need to know to stay safe when working around electricity, see our electrical safety project here.

What are Kitchen Unit Lights?

Kitchen unit lights are small strip lights or spot lights that sit underneath your kitchen wall units and when turned on, project light downwards onto your work surface, fully illuminating the work area and eliminating any shadow and shade that can make cutting and preparing food difficult.

As we’ve stated above, quite often in kitchens with only a ceiling light, when your body is between the light source and the object you’re working on it can create shadows which can make working with objects such as knives and the like quite dangerous.

By installing under unit lighting, once turned on, they fully light these otherwise shadowy areas, allowing you to have full vision over the task you’re performing.

Under unit kitchen lighting

Types of Kitchen Unit Lighting

Lighting which is "built in" to kitchen units, either under them or inside them, can largely be separated into two types, either down lights/spot lights or strip lights. Each type comes in a variety of different formats such as hard wired, mains socket or battery powered and mostly uses LED’s, but can use other types of bulb also.

Traditionally, under unit lighting would have been supplied by a 12V low voltage system, that uses a transformer to step down 240V mains power to 12V. This made it much safer to use.

Other options would also have been to use mini fluorescent strip lights fixed under each unit or a series of spot lights fixed through the bottom of the unit that projects light downwards. In most cases these were either again low voltage 12V, hard wired mains powered or featured a plug that could be plugged into a mains socket.

However today, low voltage lighting and fluorescent tubes are pretty “old hat” technology and have now been replaced by the much more modern, efficient and longer lasting LED bulbs, tubes and strips.

One of the easiest methods now of adding under unit lighting is to buy a mains plug powered LED strip that can be cut to the required length and then stuck up underneath any units, plugged in and then turned on and off via the mains plug.

Another bonus is that they are also generally low voltage so are supplied with their own transformer and due to this use hardly any electricity.

Low voltage LED strip light that can be cut to a required length

Another easy and cost effective solution can be battery powered strip lights. These again tend to use LED strip lights so use very little power and can last a long time. However as they use batteries, this does incur an extra cost and slight bit of hassle having to change them.

Easy-install battery powered LED strip light

The final route that some take is the hard wired approach. This is where the lighting is hard wired to a mains lighting circuit and either turned on and off by their own switch, by the switch for the main ceiling lights, or sometimes a combination of the 2 so each light can be independently controlled.

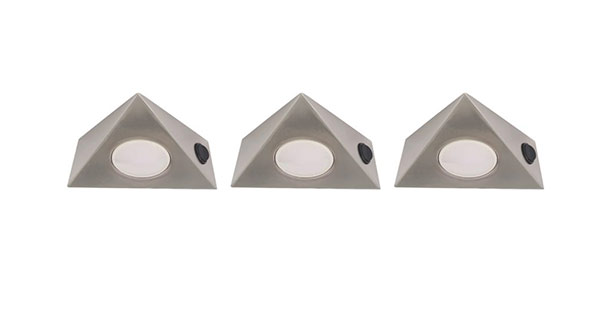

Hard wired triangular under unit lighting setup

On the whole, the strip lights tend to be much easier to install as they simply sit under each unit, where as down lights or spot lights generally need to be drilled in and installed in the base of the unit.

This isn’t so bad if the lights are being installed with a new kitchen, but if you’re retro-fitting then you’ll have to clear units out and often take them off the wall which can be tricky.

Ultimately, hard wired systems tend to be much neater as all of the wiring, transformers etc. can be hidden in behind or under the units, where as with the more DIY installs, as well as you hidden them, inevitably some will still be visible.

Should I use Warm or Cool White Under Cabinets?

If you’re using LED’s then you will need to decide what colour to use, either warm white or cool white. Generally, warm white light is best used inside the home and cool white light is best used outdoors.

Warm white light with its yellower tones tends to be a lot softer and easier to cope with in more confined spaces and doesn’t tire your eyes as much. Warmer light tends to operate between 2700K and 3000K on the lighting spectrum.

Cool white light however tends to mimic daylight much more as it’s higher up the spectrum. This tends to be around the 4000K mark. Due to this it’s generally more suited to outdoor use or in areas that benefit from a brighter light.

Switching Options for Kitchen Unit Lights

As we have commented above, when installing under unit lighting in the kitchen you will also have to decide how you want to turn them on and off. To some degree this will depend on what type of lights you are using.

For the more DIY install setups, the easiest and most straight forward solution is to simply turn them on and off using the switch on the socket they’re plugged into.

If you’re using battery-powered lighting then you really only have one choice, to use the switch built-in to the unit itself. However, in most cases you can’t see it under the unit so it can be tricky trying to find it when needed.

If you opt to go down the more integrated route and hard wire your unit lights then you will also have to install a separate 1 or possibly 2 way switch to turn them on and off.

One option is to connect them into your main ceiling light switch so everything comes on at the same time.

It is also possible to have both scenarios whereby a wall switch turns all lights on and individual unit switches turn each light off/on separately.

When going down the hard-wired route, installation normally means pulling a lot of the kitchen out to run wires and connections etc.

Sometimes there is a recess at the back of a wall unit where the connections can be made between the wiring from the wall to the wires from the light fitting and/or switch. This hides it all nicely away.

Tools and Products Needed for Installing Under Unit Lighting

To install under unit kitchen lighting you will need the following tools and materials:

- Suitable under unit lighting kit – As a full kit or lights, power cable, transformer and any other items needed

- Slim-width self adhesive trunking

- Hacksaw to cut trunking to length

- Spirit level

- Self adhesive LED strip light clips

- Self adhesive sticky pads

- Cable ties

How to Fit Kitchen Unit Lights

For the purposes of this example we are going to be installing under unit lighting using the easy to install LED reel lights.

These offer the best all round solution in that they are easy to retrofit with the minimum of fuss, produce a great level of light, are available in both cool and warm light versions and, most importantly, are very cheap to run.

Step 1 – Decide Where to Run the Wiring

The first job to do is to decide where you are going to run all of the wires that will take the power from the plug and out to each light. This will also involve deciding where to install the transformer.

The most straight forward route is to run from the socket that you’re going to power your lights from and then trace a route to each unit.

The easiest and cleanest route to take will in most cases be straight up from the plug and if there is a unit directly above, around the underside to where the light will go and then on to the next unit. This way you may have a lot of initial cable to hide.

Another route if there is no unit above is to run some trunking up from the socket to the ceiling and then over to the first unit and then down the appliance gap at the back to the base and to the light and then on to any other units.

If there are gaps between units then generally the neatest route is to run up and down the appliance gap and then run the wire in trunking between each unit, either across the wall or up to the ceiling and over.

In some cases, some wall cupboards don’t have an appliance gap and if this is the case then you won’t be able to go down this route and will have to go around the base.

It’s entirely up to you which route you take and as long as you tuck the wire up under each unit, there’s no reason not to use this route. Generally as the base of each unit is well below eye level you’ll never see it anyway.

For the purposes of this example we are going to run straight up from the plug, around the underside of the first unit and then onto the next in the same manner.

Underside of kitchen wall unit where unit lights and cable can run

Step 2 – Run Wiring to Install Positions

Once you have settled on the correct route, plug the 3-pin plug into the socket and then start to roughly trail the wire out to each unit.

Using sticky pads, apply 4 to the transformer and then stick this up under the first unit. Try to position it at the back of the unit but if you can’t, where ever it sits out of sight and has plenty of ventilation around it.

Next run a length of trunking up from the socket to the underside of the unit. The easiest to use is the self-adhesive type as you can stick it straight to the wall. Before sticking, ensure it’s vertically level using a spirit level.

Run the power cord from the plug up the trunking and then clip the cap in place.

Using a cable tie, neatly gather up any excess power cord and then stick it up under the unit near to the transformer.

There should also be a length of power cable running from the transformer to the LED strip. You may need to unravel some of this but if not ensure it’s neatly tied up with a cable tie and then stick it up out the way.

Step 3 – Fix Lighting in Place

Next, using self adhesive light strip mounting clips (such as those below), clip up the LED strip under the unit ensuring each LED diode if facing downwards onto the work surface.

Generally it’s best to position them behind the lip at the front of the unit so that it illuminates the entire work surface and not just out from the back.

Once the first unit is dealt with, run the strip to the second unit and fix it in place using the same technique.

Ensure that the strip is flush with the base of the unit and not drooping down where it can be seen.

LED reel light self adhesive cable clips

Step 4 – Plug in and Test

Once all of the LED strip has been run out to each unit and fixed in place the final job now is to turn it on and test it.

If the plug isn’t still plugged in, plug it in, otherwise flick the socket switch on and any other power switches there may be and if all is well, your work surfaces should be beautifully illuminated, good work!

Well lit work surface due to under unit LED lighting

Installing under unit kitchen lighting can be a very straight forward DIY job and one that can be done for very little money and additional cost.