When it comes to lighting solutions for a room, downlights or recessed downlights as they are also known are always a fantastic choice as they are so versatile and also they suit pretty much any style from modern to traditional.

Having spot lights recessed into your ceiling is a fantastic way to light a room, especially where it is not practical to have other types of lighting, such as a pendant lights and the similar as due to their directional nature, pendant lights are not as effective, particularly in bathrooms or kitchens.

In this DIY guide we take a look at all aspects of downlights including how they are installed.

Rules and Regulations for Downlights and Electrics

As with any building or construction related task there are a list of rules and regulations governing how a particular job should be done and, more importantly, exactly who can do it. Due to the dangers associated with electricity, the regulations are extremely strict and rightly so.

When it comes to electrics and the regulations, the relevant documents to adhere are the BS7671 Wiring Regulations and Part P of the Building Regulations.

As a very rough outline, if you aren’t a registered Part P electrician then there is in fact very few jobs you can actually do, other than changing the odd existing socket or switch face plate or existing light fitting.

When it comes to installing downlights, effectively if you are changing 1 existing light fitting for 1 single downlight then technically you are allowed to do this, but in reality no one is going to use just 1 downlight so would likely be installing more and as this means changing the earth path then this is notifiable works and can only be done by a qualified electrician that can then sign it off.

Additionally, as downlights are mostly installed in kitchens and bathrooms then these are regarded as “special locations” and the electrics in areas such as these can only be worked on by, again, a Part P registered electrician.

However, despite this, if you are simply changing an existing downlight for a new one of the exact same type then as this was originally checked and signed off and you’re not changing the actual earth path or circuit you are able to do this.

Downlights can transform a room – Image courtesy of Lighting Matters

Now we’ve got the important safety information out the way, let’s get on with the rest of the information.

Types of Downlights

Before anything actually gets installed it’s important to know about the different types of downlights and where they should be used, especially if you are buying your own lights to be later fitted by an electrician.

You don’t want him or her turning up and stating that you have the wrong type for the area they are to be fitted in.

IP20 Downlights

These are the most basic and cheapest type of downlight and represent the most versatile type as they can be used in a variety of locations and rooms, except really for any of the special locations e.g. bathrooms and the likes where they would require an IP rating to prevent any water ingress.

As they are fixed they only project light straight downwards but as long as they are sensibly spaced across a ceiling then they will project more than enough light to prevent any shadows or shaded areas.

Despite the fact that they are fixed it is possible to also get adjustable versions that can be angled to project light over adjacent areas.

IP44 Downlights

These types of downlights are moderately sealed to help prevent moisture and dust ingress and due to this can be used outdoors, most commonly fixed into soffits and the similar to provide external lighting.

As the built in seals only protect from slight indirect splashing and not any from of direct pressurised water or moisture they should be sited somewhere fairly protected.

Additionally when selecting your lights, make sure that the actual construction materials are suitable for placing outdoors e.g. they are plastic, stainless steel etc. to ensure they don’t rust or degrade too badly.

IP65 Downlights

The IP65 downlight is mainly exclusively used for installations in bathrooms as they feature a built-in seal that prevents pretty much any and all water, moisture and dust ingress, even pressurised!

Like their IP20 counterparts they are also available as adjustable meaning that you can change the angle of the light to project elsewhere, however there aren’t that many manufacturers that produce these.

Square Downlights – Single to Quadruple

Square downlights are a relatively recent thing and are quite modern and contemporary in appearance. Although they are called square it’s really only the actual housing that’s square, not the actual bulb, this is still the standard type GU10 or MR16 round bulb, however if you are looking for something a little different then they certainly stand out.

Aside form the typical single downlight, square downlights are also available in double, triple and quadruple variants, with 2, 3 or 4 bulbs in the same unit. Again some manufacturers also make adjustable versions.

Plaster-in Downlights

As the name suggests, these types of downlights are actually plastered into the ceiling to create a much more contemporary and minimal look and feel. Despite the fact that they are essentially permanently fitted into the ceiling, bulbs can still be easily changed in the unlikely (with modern LED bulbs) event they fail.

As they are actually integrated into the ceiling they don’t feature the typical chunky bezel that all other variants have.

LED Spot Downlights

Although when thinking of downlights you may automatically think of the recessed type we have mentioned above, it’s also common to categorise the surface mounted spotlight cluster as a form of downlight as, although they are mounted in an external unit fixed to the ceiling, they still actually use downlights as their lighting source.

As with all of the other variants above, LED spot downlights come in a range of types from fixed to adjustable and also up to IP65.

As mentioned above, downlights are avaialble in a range of different bulb fitments including GU10, MR16, MR11 and all the other types. For a full description of each, see our LED lighting project here.

It’s also worth mentioning that, traditionally for special locations, you would need to use low voltage downlights. These feature a step down transformer that coverts the 230/240 volt electric down to 12v, which, in the event of an issue, poses much less of a risk than full voltage.

The downside of this is that the transformer generates a lot of heat which in turn then becomes a fire risk and when placed around the insulation often found in a ceiling, this risk is pretty large so need to be used with fire hoods and the like. However, LED bulbs generate substantially less heat so are a much safer choice.

Should you use 12 Volt or 230 Volt lights?

It used to be popular to use 12 Volt lights in kitchens and bathrooms because they offered a better light and also had the benefit of being lower voltage, however they need a transformer to step the voltage down which will get hot so needs to be ventilated.

With the advent of LED lights, there is no need to go for 12 volt lights as LEDs come in all the different light intensities and colours you could want and have dimmable versions, so there is no real benefit to using 12 Volt anymore. It is less complicated to simply stick with 230 Volt and use LED bulbs.

Which is Best for Downlights – LED or Halogen?

Halogen lights were a huge technological leap forward in their day, however they are only about 30% more efficient than old fashioned incandescent bulbs and will only last about 2 years (based on 3 hours usage everyday). They also get hot so consideration needs to be given to ventilation.

LED lights offer the same light quality, are 90% more energy efficient than old fashioned bulbs, and will last of 25 years when used 3 hours a day. They are a little more expensive, but well worth the extra cost. For us it is LEDs every time.

Should the Downlights be Fire Rated?

The ceiling is an important fire barrier to slow the spread of a fire to upper floors. Peppering this with holes will not help, so you should fill these holes with fire rated lights and in many cases the regulations will ensure you have to – see more information in the Building Regulations Approved Document B all about fire safety.

What Other Ratings for Downlighters do you Need to Consider?

You must consider the safety zones in bathroom where the lights are going to be fitted (which you can find all about here) as you will need to use IP rated lights in these zones. You need to ensure that you are using the right IP rated light in the zone you are planning to have the lights fitted.

There are acoustic rated downlights which you can consider using if there is a problem with noise from the floor above.

Are Integrated Downlights Better or Worse Than Standard Downlights?

Integrated downlights are lights where the blub is fitted inside them and cannot be removed, hence the name integrated. Because LED bulbs have such a long life it is considered that they will outlast the life of the light itself, or at least provide sufficient life.

With standard downlighters you can change the bulb as normal. Which offer more flexibility should you need to, or if you want to change to a different tone light.

The big danger is that if one light fails and you cannot get a matching replacement, if the model has been discontinued for example (which might well happen in the long life of these lights), then you have to replace the whole lot if you want them to match.

Tools and Products Needed for Fitting Downlights

When installing spot lights in a ceiling, the following tools and products are required:

- Drill/driver

- Set of hole saws

- Small flat blade screwdriver

- Philips screwdriver

- Required quantity of downlights to replace existing lights

- Tape measure

- Spirit level

- Pen/pencil

- Stud and cable detector

- Utility knife

- Electrical side cutters

- Wire strippers

- Laser level

Fitting Downlights

There are really only 5 steps to fitting downlights or ceiling spots:

- Mark downlight positions on ceiling

- Cut holes for downlights

- Wire up downlights

- Inserting downlights into your ceiling

- Test Installation

If you are simply replacing your spots with something a little more modern or are up grading to LED lighting then you can jump straight to the 3 stage, as stage 1 and 2 will have already been done.

Step 1 – Positioning Downlights for Installation

The very first job before anything else is to isolate the circuit that’s being worked on. This is done by either removing the fuse, if the supply is from an old style fuse box or by switching off the MCB if it’s a consumer unit.

The next job is to confirm that, by fitting downlights, this isn’t going to compromise fire safety or the Building Regulations. This is really only a consideration for old style downlights or low voltage lighting that uses a transformer. If fitting modern LED’s, they produce hardly any heat so should be fine.

Another factor is that by drilling lots of holes in the ceiling, this can also affect how fire spreads in the event of a fire; the ceiling will slow the spread of a fire but it will not be as effective if it is peppered with holes for downlights. There are fire rated downlights which should be use in these situations, and we suggest should always be used for safety’s sake.

Positioning your spotlights is something that needs some careful consideration. In a kitchen they should be positioned over the worktop so that they don’t cast a shadow when you’re preparing food; typical kitchen units will be 600mm wide so you should keep within this distance from the wall ideally.

Position the down-lights to cast light on work surfaces – Image courtesy of Ablelectrics

The number of lights needed will depend on the brightness of the lamp or bulb and what you are going to use the space for. In a kitchen you’ll need brighter lighting than in a living room and a good measure for the brightness can be approximated by using Watts or “equivalent Watts” if you are planning to use LED bulbs.

It is typical to have the spots spaced at between 1.2 m (4ft) and 1.5 m (5ft) as this gives a more than suitable level of light, but this is entirely up to you, and people tend to suggest it is better to have more rather than less, as you can zone the lighting with switches or have a dimmer switch to tone it down if necessary.

A handy way to approximate how many downlights you will need is using this method:

- Calculate the room area (length X width) in feet – e.g., 8ft X 15ft = 120 ft2

- Multiply by a lighting factor – 1.5 for a living room or 2.5 for an area which needs more light like a kitchen for example – e.g. 120 ft2 X 1.5 = 180 Watts

- Divide the Watts needed to light the room you have calculated by equivalent Wattage of the bulbs that you’ll be using to give the number of bulbs you will need – e.g. 180 Watts ÷ 35 Watts = 5.1. Therefore you will need between 5 & 6 recessed lights

But, of course, it is entirely up to you how many you have!

The big thing to watch out for is where the joist or any other obstructions might be. If you cannot get access from above, either from the loft or by lifting the floor boards, use a stud detector to do this and also to see if there are any pipes or cables that are going to cause you problems.

Joists will be (should be!) evenly spaced so once you know the spacing you can predict where they will be, meaning that you can avoid putting your holes for the downlighters within around 6 inches of a joist, ideally.

Mark the ceiling at the centre of each spot. Keeping everything level and inline is a real task, especially on a ceiling, so for this the best tool to use is a laser level so that you have a perfect straight line to work along. Once the first set of markings are done then it’s easy to work out from this.

If you don’t have a laser level you can easily hire one. If not then you will need to measure and mark out from each wall and use a spirit level. Get an extra pair of hands for this, you’ll need them!

When you are happy with the positioning and your markings you are ready for the next step.

Step 2 – Cutting the Holes for Downlights

Once you know where each downlighter will be fitted, then you should drill a small pilot hole at the centre of each light position.

Once drilled, go above the ceiling to confirm that each one will be clear to cut or drill the larger hole for the down lighter without hitting anything.

The light from below should shine through, or you might need to stick something through so you can see the position of each one.

If you can’t get access to the ceiling from above you will need to clear the area by sticking a piece of bent wire through the pilot hole and twisting it around to feel for any unseen obstructions.

In these instances running new cables if needed can be a real job, fortunately there is a way to fish cables through walls and ceiling; See our fishing cables through walls and ceilings project here for more information.

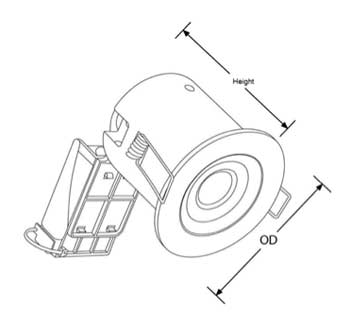

In terms of the size of hole, there are three key dimensions that you need to make a note of for fitting your lights:

- Cut out – This is the size of the hole you need to cut in the ceiling to insert the light. This dimension is normally provided on the box containing the light or stated in the instructions

- Height – This is the height of the lighting unit; there are low profile lights if you have limited space above your ceiling

- Overall Diameter – (OS) this is the size of the light that will be visible on the ceiling

The key measurements for a downlight

Typically domestic downlights use a cut out of 80mm, although there is a huge range from anything from 30mm to 200mm and more. Mini downlighters usually require cut outs in the region of 60mm, and under cabinet lights are less than 50mm.

The other key measurement for fitting is the height as the space above the ceiling will determine what you can use. Larger lights with larger cut outs will generally have a greater height.

Typical heights for 80mm cut out lights are in the region of 75 – 110mm typically, although it is possible to find “low profile” models should space be really tight.

Under cabinet downlights are often designed to be surface mounted and therefore have heights of around 15mm.

With so much variety you simply have to check the design that you want and ensure that the measurements are going to fit in your ceiling. If it doesn’t there is sure to be one that will if you shop about.

There will be instructions with the downlighters kits that you buy so you should follow these and go with the size holes etc. that they state.

Often there is a template to mark out the size of the circle you need to cut out, however if not you can either draw the right size with a pair of compasses and pencil or use the correct sized hole saw guided by the pilot drill bit at the centre.

Top Tip: Often you will have yet to have plastered the ceiling, so drawing on it is no problem as the plaster will cover any marks you make. However if it’s already finished, try to limit any markings and use a pencil so that you can rub out afterwards.

Once the holes are marked you are ready to cut them out; you can do this by hand using a Plasterboard or Pad Saw or preferably you could use a hole saw.

Top Tip: Use a cheap or old hole saw as drilling into plasterboard is not good for them and blunts them quickly.

A good idea to use a dust-catcher when drilling holes above your head. It both saves dust going in your eyes and onto the floor.

Now you will have your holes it is time to connect up the electrics.

Step 3 – Wire up Downlights

The next step is getting the cables run in for the lights. Generally, the electrician doing the work will run a cable from the consumer unit or from an existing source down to the switch that’s being used to control them and then out to each hole. A loop is pulled or pushed through each hole before it’s run on to the next hole.

How the wiring is done will really depend on the electrician, some will simply have a central supply cable and then use junction boxes to run a single supply wire to the light location.

If the lights are being zoned e.g. 2 separate switches will control 2 separate banks of lights, your electrician will wire this appropriately.

In terms of the actual source, if it’s a brand new circuit then it will probably run from it’s own MCB in the consumer unit however if it’s an existing circuit, for example a single kitchen light is being turned into multiple string of downlights, then any new cableing will likely run from the existing supply cable, but your electrician will know what’s suitable and will conform to the regulations.

Downlights are wired as a radial circuit which means that they are all in a line and end with the final loop as opposed to going back to the consumer unit as a ring main would.

It’s also essential that the correct cable is used. In most cases 1mm twin and earth should be fine but if it’s a particularly long circuit, there are many lights or they are particularly powerful then 1.5mm twin and earth will need to be used. The electrician doing the work will know exactly what to use.

If you would like to know more about how lighting circuits are wired up then see our project on wiring lighting circuits here.

Cables laid ready to connect the downlights – Image Courtesy of Fuseservice

Once all the cables are run then the base of each loop is cut (if looped) and each end stripped off or if a single cable, the end of this is stripped and then a junction box or connector (usually called a chocbox) is used to connect the cable of the light to the supply and also the other end of the cable that runs to the next light.

Ensure that the correct wires are joined together e.g. brown lives to brown lives, blue neutrals to blue neutrals and earths to earths.

A Chocbox can be used to connect any cables

At this point you will have the connected downlights hanging from the ceiling. All that remains is insert the light into its place in the ceiling.

The Downlight connected and ready to be inserted into the ceiling

Finally, once the circuit is yet again tested to ensure it’s isolated, the end of the supply cable is connected to it’s MCB, if it’s a brand new circuit, or if an existing circuit, most likely using a junction box, is then connected to the existing supply.

Step 4 – Inserting Downlights into your Ceiling

Fitting the lights into their holes is the easy bit!

Generally there are springs on the side of the light unit which is going to be recessed into the ceiling. Squeeze these in so that the light can be pushed up into the hole that you have cut out.

Inserting a recessed downlight

As the light slides into the hole, the wire spring catches will catch on the ceiling and force out the springs so that they push down on the upper side of the ceiling boards holding the light unit in place.

Slide the light unit into the hole you have cut in the ceiling

Step 5 – Test Installation

The final step of the process, once all the lights are fitted, that the power is turned on and the electrician will then test the circuit fully to ensure all is as it should be.

Once it’s been fully tested he will then issue you a minor works certificate to prove all has been done to the regulations standard!

Adding downlights to your kitchen, bathroom or any other room in your home can really transform it and give it a whole new dimension. Although the work needs to be done by an electrician, or certainly checked and signed off by one to abide by the regulations it’s also one that can be done fairly cheaply, and once complete you will be glad you spent the money.