There are quite a few different shapes of toilet around today and many different types of toilet seat to match.

Fitting a toilet seat can be a little tricky as there are several different ways they are secured depending on the type of fixing that’s been used and how old the toilet is, however if some simple rules are followed, it’s certainly one that can be done by anyone.

Types of Toilet Seat

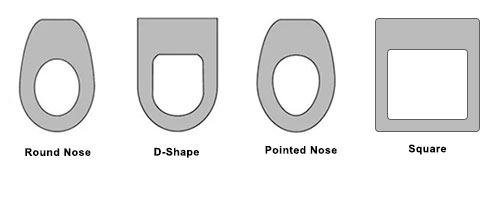

There are 4 standard types of toilet seat currently available and these are pointed nose, rounded nose, D-shape and square and depending on the type and age of toilet you have will depend on the type of seat that’s used.

In pretty much all cases your toilet will be shaped to fit a particular type of seat so replacing a toilet seat will have to be done on a like-for-like basis so that you can be sure that it fits correctly.

- Pointed Nose: One of the most common types of toilet seat and used for more traditional toilets, they are comfortable to use but are slightly larger than rounded seats

- Rounded Nose: The traditional shape of toilet seat and due to this probably the most common, they are also smaller than other designs so ideal for smaller bathrooms

- D-Shape: These seats tend to be modern so suit modern bathrooms and toilets and they are a little larger than more traditional toilets

- Square: Arguably the most modern type of toilet and seat, they suit modern properties and design schemes. Due to they’re sharp angles they are a little larger so suit larger more spacious bathrooms

The most common shapes of toilet seat – from left to right, round nose, traditional pointed nose, D-shaped and square

Over the years even the same shaped toilets have changed slightly in size so to allow for this and ensure that newer toilet seats will fit older toilets that may be slightly smaller, replacement toilet seat kits usually have adjustment to allow fitting to the older or non standard types as well.

To ensure that a toilet seat lasts as long as possible and supports anyone sitting on it, it is essential that the seat is supported by the pan at all the contact points.

One final type of toilet seat is the wrap over seat. Although more of a design of seat than an individual type, all of the above types of seat can be purchased in a wrap over design.

What “wrap over” actually means is that the lid of the seat wraps over and covers the actual seat all the way down to the top of the pan. This not only gives a more modern and minimal look but also helps to keep things more hygienic.

Wrap over toilet seat

Types of Toilet Seat Fixings

Toilet seat fixings tend to be slightly different between manufacturers and due to this there are quite a few, however despite this they can all be broken into 2 different types; bottom fixing and top fixing.

Bottom Fixing Toilet Seats

The bottom fixing is the traditional way to fix a toilet seat to a toilet and because of this they are the most common.

Typically the toilet seat is fixed to the pan by two long screws, one end runs through the base of the hinge and then through the pan using the holes supplied by the manufacturer. A washer and nut are then added and tightened from underneath that then holds the seat in place.

In the cheaper models the screws are made from plastic however the majority are made from steel and the most expensive come in stainless steel or brass. One thing to note is that due to the wet environment, plated metal fixings can corrode quickly.

To identify how your toilet seat is fixed, simply look directly under the back of the hinge under the edge of the pan and if there is a bolt and nut then you have a bottom fixing.

Bottom fixing toilet seat

Top Fixing Toilet Seats

The top fixing method for toilet seats tends to be more modern and due to this is generally featured on modern toilet seats.

As you would imagine, instead of a securing the seat in place from below using a nut on a bolt that runs through the pan, the fixings are screwed down from the top into the top of the pan in the same way you would screw a screw into a piece of wood.

The fixing itself normally works in the same way as a wall plug. A plastic sleeve pushes down into the hole in the pan and then a screw or bolt screws down in. As it screws in the sleeve expands and grips tightly in the hole holding it firmly in place.

Some manufacturers utilise a metal fixing that uses a barrel nut positioned under the pan and the bolt is screwed down from the top.

The big advantage that the top fixing method has is that they are much easier to fit and also maintain.

Top fixing toilet seat plugs

Parts of a Toilet Seat

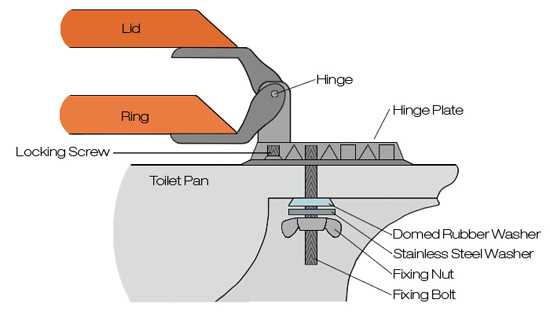

The key parts of a toilet seat include the ring, lid, hinge, hinge plate and the seat fixing and are show in the diagram below. It is helpful to understand these parts and how they interact to keep the seat fixed on the toilet pan and stop it wobbling or sliding.

- Lid: The lid covers the ring and the toilet pan

- Ring: The part of the seat you sit on

- Hinge: The hinge holds the lid and the ring together

- Hinge Plate: Sits on top the toilet pan and connects to the hinge

- Fixing (domed, stainless washers, fixing nut and bolt): Connects to the hinge plate and fixes everything to the toilet pan

The key parts of a toilet seat and its fixings

Materials Used to make Toilet Seats

Toilet seats are generally made of one of 2 different materials: wood or plastic. Depending on the style and longevity you are going for will depend on what type of seat material is best suited to your needs.

Wooden Toilet Seats

Wood was the traditional material used for toilet seat production and overall produces a good solid and long lasting seat.

Available in a vast range of different styles, wooden seats are both comfortable and warmer than plastic in the cold.

Some disadvantages however are that cheap wooden seats made of MDF don’t tend to last that long as they wear quickly, but the harder-wearing hardwood options tend to be quite expensive.

Wooden toilet seat

Plastic Toilet Seats

The most common type of toilet seat found in homes across the UK is the plastic toilet seat due to it’s ease of cleaning and cheap cost both to produce and buy.

As plastic is a fairly tough, hardwearing and durable material they also last a good amount of time.

Plastic toilet seats also come in a massive range of styles and designs so there is sure to be an option that suits your particular needs.

Standard plastic toilet seat

One type of plastic toilet seat that deserves a special mention is the resin seat. This is due to the fact that they differ slightly in that resin is slightly tougher and harder wearing than standard plastic and, apart from a massive range of different colours and styles, they can also have images and objects inset into them.

Resin toilet seat

How to Measure a Toilet Seat

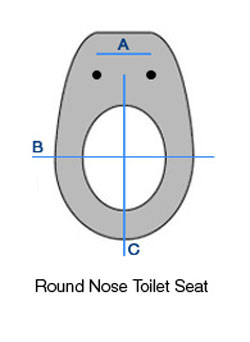

When replacing a toilet seat you have to be absolutely sure that you are replacing the old one with one of exactly the same size so that all supports on the base of the ring sit flat on top of the pan

To do so you will need to take 3 key toilet seat measurements that include:

- Measure the distance between the fixing holes. This is typically a standard measurement of 155mm, but it is worth checking

- Measure the width of the bowl where it is widest

- Measure from the very front of the bowl back to an imaginary line joining the two seat fixing holes

Although most seats and fittings are adjustable so that they will fit the most common toilet bowl shapes, you still need to ensure it’s the right size.

The key areas to measure on your toilet when looking to buy a new toilet seat

With these measurements you can then make sure that you get the right sized toilet seat.

Safety Precautions When Working Around Toilets

When working with toilets, health and safety must come first! The toilet is obviously a place that can harbour harmful germs and is a source of potential infection therefore precautions should be taken before starting the job.

Before starting anything use an anti-bacterial spray which kills most bacteria and fungi, such as E.coli, Salmonella, viruses and may other things to clean every part of your toilet down.

Ideally you should wear gloves for the whole job but this is not always practical. Disposable, thin type latex gloves tend to tear and split but the thicker gloves tend to numb the sense of “feeling” what you are doing.

If you prefer to work without gloves, first start by squeezing a little barrier cream onto your hands and massaging this in all over both hands back and front.

Have some anti-bacterial cleaning spray to hand for cleaning the pan when the older seat is removed and before the new one goes on. The same cleaning agent can then be used when washing your hands after the job is done – assuming you are not sensitive to such cleaning chemicals. Always test for this, if you are not sure or have not used the product before.

Once finished you should also clean any and all tools that you have used.

Tools Needed to Change a Toilet Seat

Depending on the type of seat or seat fixings you’re using, tools may not be needed. However it’s a good idea to have a basic set to hand:

- New toilet seat (if needed)

- Pair of pliers

- Adjustable spanner

- Set of spanners (for metal nuts and bolts)

- Flat head and Philips screwdrivers

- Toilet seat fitting kit (if needed)

- PPE such as old clothes, gloves etc.

- Suitable cleaning equipment (anti bacterial spray, cloth etc.)

Typical stainless steel toilet seat fitting kit that includes hinges and bolts

How to Remove a Toilet Seat

Removing a toilet seat is a fairly straight forward and simple job, however depending on how long it’s been there and how often and thoroughly it’s cleaned it’s one that may not be that pleasant as you will probably need to get on the floor and up under the back.

Step 1 – Have a Clean

As we have mentioned the first job should be to have a clean around and wipe away any dirt and grime to make the working area safer and a bit more pleasant to be in.

Try to clean around the fixing bolts and clean as thoroughly as you can.

Step 2 – Unscrew Fixings

Depending on the type of fixings your seat uses will depend on how they are removed. For top fixings, either remove the ring and lid (if you need to) or flip up the hinge plate cover to reveal the bolt or screw head. Using the correct tool, unscrew the bolt or screw and repeat for the other side.

Cap removed showing top fixing for toilet seat

For bottom fixings you will need to look and feel for a plastic winged nut under the pan (in most cases this will be plastic, but in some situations could also be metal). Sometimes you are lucky, as shown below and this is easy to get to, but in other case it can be very awkward to reach.

Where metal nuts or wing nuts are used, depending on how old they are they might be very corroded and can be a nightmare to remove. If this is the case, soak them in WD40 or a similar easing fluid.

The wing nut that needs unscrewing to remove your loo seat

Step 3 – Remove Old Seat

Once the nuts holding the seat in place are removed you can simply lift it away and free from the pan.

Once it’s out of the way you can then thoroughly clean the whole area before refitting your new seat.

Fitting a New Toilet Seat

Fitting a new toilet seat is basically a reversal of the removal process. Make sure that the nuts are secure but not overly tight, as the plastic screws will not take a lot of punishment before they give way and strip the threads or snap.

In most cases, manufacturers tend to fit the actual hinge brackets to the seat assembly so it’s just a case of then fixing the short studs to the base of the hinge plate.

For the purposes of this guide we are going to run through fitting a seat using bottom fixing bolts.

Step 1 – Fit Studs to Hinge Plate

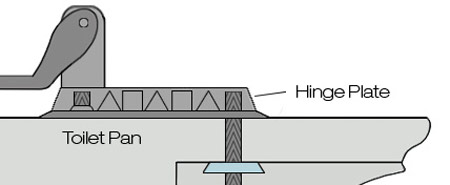

The first step is to screw the short studded sections into the base of the hinge plate. The one thing that you need to ensure is that if there are a range of different holes in the base, that you screw the stud into the right hole.

The different holes are there for adjustment of the seat position so you want to ensure that:

- Both hinges sit straight and level when studs are in holes

- The seat sits square on top of the pan

- When the lid and ring are raised they can be rested on the cistern without falling forwards

To find the correct hole, loosely screw the studs in and position the seat in place and ensure all points above are met.

Once you have found the correct holes, screw the studs in tightly.

Finally, slip the vinyl or plastic washer over the stud and slide it up to the hinge plate. This sits between the hinge plate and pan and protects the pan from scratching.

Step 2 – Adjust the Hinges

Some seats, as well as the 3 points below allow you to adjust the hinges using a locking screw below the hinge, passing through the hinge plate. Make any adjustment necessary then tighten the screw. If there is no screw then adjustment needs to be made using one of the following methods if they exist.

Typically there are three adjustments that you can make:

- Fine adjustments can be made by rotating the hinge plate; this ensures that the fixing bolts can be adjusted so both will go into their respective holes in the toilet bowl

- To adjust the position of whole seat forward (or backwards), it is possible to turn both the hinge plates 180°. This moves the seat forwards or backwards away from the front of the bowl. It also moves the hinge forward so that the seat (Lid and Ring) can rest against the cistern without falling down

- As we have mentioned, in some toilet seat fixing brackets there are other holes into which the fixing stud can be screwed into, this has the same effect at turning the hinge plate as described above, but allows further adjustment which would not be possible otherwise. In cheaper seats the fixing bolt is prefixed so this is not an option

Altering the location of the fixing bolt in the hinge plate can move the position of the hinge forward

As we have said, the tricky part when it comes to adjustment is, especially with close-coupled suites, to ensure that the adjustment of the seat allows for both sections to be lifted and leant against the cistern whilst also allowing the seat to be supported at all contact points to the top rim of the pan.

The downside to fittings with so many points of adjustment is that it’s easy for movement in the seat to occur, causing a wobbly seat over time, so you need to ensure everything is tight.

Step 3 – Tighten the Hinge Locking Screw

If there is a hinge lock screw present, even if you don’t adjust the hinge, tighten the screw fully! If not tight this will work loose further and cause the seat to become loose and wobble and slide on top of the bowl, which is annoying.

The only solution to fix this is to remove the seat and tighten this properly. Most people forget to do this in the excitement of fitting their new seat!

Step 4 – Fit Seat and Fixings

With the lid and ring flat to the top of the toilet pan and the hige and hinge plate in the same position, lower it down on to the pan, slotting the studs through the fixing holes.

Make sure the fit is good and that the hinge plates are both pointing in the same direction and the seat is sitting evenly around the perimeter of the toilet bowl.

Step 5 – Fit Washer and Nuts

Get a good view of the studs while you work as it makes things easier and fit the washers and securing nut. This can be very fiddly, but make sure you get them in the right order, as there should be no metal pressing on the ceramic of the pan as it can damage it, they should be fitted as follows:

- Rubber or plastic washer first – to protect the pan

- Metal washer next (if there is one) – to spread the pressure

- Fixing nut at the bottom – holding everything on firmly

If your studs and wingnut or nut are plastic then, as we have said, don’t over tighten them as you can easily strip them.

Likewise if they are metal, if you over tighten to the extreme then, worse case, you can crack the toilet due to the pressure!

Just tighten to the point there is no movement.

Fixing holding toilet seat and hinge to toilet pan

Step 6 – Re-Tighten Nuts

The final job, after a few days, is to retighten the fixing nuts once more. As any rubber and plastic compresses it can create a bit of movement and play so this needs to be taken up by tightening the nuts a little further.

Top Tip from the Doctor:

A tip you may find useful is that, having got the adjustment correct in step 2, before securing the seat to the pan, note the positions and then unscrew the main adjusting screw and the studs and coat the threads with a proprietary thread seal.

This will help to reduce the possibility of any movement..

Fitting Top Fixing Toilet Seat Fittings

Fitting a toilet seat using top fixings is fairly similar to a bottom fix seat, with the difference of exactly where the fixings are located. Follow the steps below to fit one:

Step 1 – Insert Top Fixing Plugs

The first job is to insert the top fixing plugs into the fixing holes on the back of the toilet pan. There are numerous different types but most of the plastic ones simply push down into the hole in the same way a wall plug would go into a hole in the wall.

If you have metal fixings these can be a little different and may need fitting from below. If you have any doubts then refer to the manufacturers fitting instructions that came with the kit.

Step 2 – Position and Fix Hinges

Depending on what type of hinges you have will depend on how they are fixed. Some hinges have no adjustment and simply fix in one position and if this is the case for yours then simply position them over the fixing plugs, insert the screw down through the hinge and into the plug and then screw it up.

However if the hinges you have feature adjustment then they will need to be positioned and adjusted correctly so the seat sits in exactly the right place on top the pan before the screws are tightened.

As there are many different types of adjustable top fixing hinges you will need to refer to the manufacturers instructions included with the kit on how to adjust correctly.

However, once adjusted, hold the hinge so it doesn’t move, pop the screw down in and screw it up tight and then repeat for the other side.

Step 3 – Fit Seat in Place

The final job with the hinges fitted is to pop the seat on. This is simply a case of lining up the holes on the seat and then dropping it down on the hinge pins. Gently push it down until it clicks and then you’re done.

Finally lift both sections of the seat up and down to make sure all is moving ok.

Fitted top fixing toilet seat

For most top fixing toilet seats, the seat and hinges are supplied separately and fitted as described above, however with a few kits, the hinges come fitted to the seat.

These kits are even easier to fit as all you have to do is insert the fixing plugs into the pan, position the seat in place and ensure it’s uniform to the top of the pan and then insert the screws and screw them up and you’re finished.

Tips for Fitting Non-Standard Toilet Seats

Aside from the 2 most common types of toilet seat fixings stated above there are several others, although not that common, if the methods above don’t seem to fit the seat you have then read on below as you may have one of these.

Toilet Seat with Hinge Bar and grub Screws

Another variation of seat fitting involves brackets that fit through the pan in the conventional manner, but with a variation that they also incorporate a spigot that locates with a metal bar that acts as the hinge.

This bar has 2 blind holes and the method is to locate the spigots into the blind holes which also incorporate a tiny grub screw with an Allen head. A tiny Allen key is required to secure the grub screws to the spigot.

It is quite fiddly as grub screws face the cistern and therefore one cannot see these grub screws once the seat is in position.

Slow Automatic Closure Toilet Seats

Another variation of modern seats involves a slow automatic closure. It is important to note that the brackets that come with these kits are left hand/right hand and to follow the manufacturer’s instructions very carefully.

To be effective, these seats cannot be raised and leant against the cistern with an angle over 110 degrees, therefore they may not fit in every location.

Back to the Wall Pan Toilet Seat

There are specialty toilet seats to suit the back-to-the-wall pan, where access to the underneath of the pan is denied.

The seat brackets for this type of eventuality involve a one-piece expansive fitting similar in principle to a cavity wall fitting, where the securing screw is encapsulated by a long rubber grommet with the securing nut at the end.

The method is to fit the rubber grommet into the pan holes and tighten the screw that engages with the nut and as one tightens, the nut is drawn up by the screwing action that expands the rubber grommet, making it tighten within the hole in the pan.

This is a very good and well thought out solution for this eventuality and saves having to withdraw the pan from the wall, where re-sealing is difficult.

This is essentially the same as a top fixing.

Troubleshooting Problems With Toilet Seats

There are 3 main complaints that we hear about toilet seats, and generally they are easily dealt with (if your seat is of a reasonable quality):

My Toilet Seat Slides, Wobbles or is Unsteady

This is because something is loose. There are a number of options:

- The hinge locking screw is loose – please see step 2 in the fitting instructions above. Commonly this (or it’s equivalent) is not tightened

- The fixing bolt needs to be tightened – this may have worked loose or the washer has become more compressed allowing some play into the fixing bracket

- The fixing bolt or washer has failed – this sometimes occurs with cheaper seats with plastic fixing bolts. They can be tightened but typically it will fail again. Best solution is to replace it

My Toilet Seat Falls Down Whenever I Stand it up Against the Cistern

This is because the hinge is too far back. This can be easily fixed by adjusting the hinge position using the 3 options described in step 2 above.

For a man this is one of the most annoying things in existence – you know how we cannot multitask! Thankfully the solution is quick and easy.

My Toilet Seat is too Far Back so My Legs Touch the Bowl when I Sit on the Loo

This is because the hinge is too far forward. The solution is exactly the opposite of the above – the hinge needs to be moved back rather than forward. If the hinge cannot be moved back or if doing so causes it to fall down when raised then you have the wrong size seat. You will need to get the right size seat for your bowl.

If you have any other bathroom or toilet related problems we have a list of toilet related project pages which explain everything from how to fit a new toilet to how to fix a toilet that wont flush to how to mend a push button toilet cistern.

If you are thinking of changing your toilet from a close coupled to a low level toilet, take a look at the project we have on this, the old seat may not fit the new loo.

This is the end of your “Toilet Training”! By know you should feel confident on removing a toilet seat and also how to adjust or fit a toilet seat. It can be a fiddly job, but replacing a loo seat is a job that anyone can do easily.