How to Mend Cracks in Concrete Paths

For more advice on mending cracks in concrete we have a whole page dedicated to the subject. Click on this link to see how to make permanent repairs to concrete paths and drives.

Epoxy resin mortar can be used to repair cracks in concrete

You will see how epoxy resin mortars can be used very effectively as a substitute concrete for repairing concrete paths and drives ensuring, because of the flexibility of epoxy mortars, that cracks do not develop again.

You will also see a range of materials developed to protect your patios, paths and drives against movement and cracking as well as a number of retrospective repair measures.

Common path materials such as stone slabs, concrete slabs and block paving slabs are ideal for making paths

What Causes Paths to Crack and Break up?

Mending cracks in concrete paths, patios, drives, walls and floors has long been a problem for both the builder and the DIY enthusiast. New concrete in a crack is completely useless unless the crack can be widened into something which will allow a decent amount of concrete to be placed in it. Its no good trying to fill a 5mm crack with concrete comprised of 10mm aggregate!

Weeds are not always the cause of cracked paths

It is also important to remember that paths made of concrete, paving slabs, bricks and other solid materials are just that…..solid!

They will not expand and contract as the rest of the ground will and when an immovable force such as cast concrete, meets an unstoppable object such as ice expanding in a small crack, the result is always a broken path.

Concrete is waterproof when it is all in one piece but any slight movement (caused simply by the expansion and contraction of the different materials it is comprised of) can cause the concrete to crack.

When there is the tiniest crack, water can get in. The water freezes in the winter and expands into ise which enlarges the crack and so on. For more on this please visit our page on Freeze-Thaw action..

Liquids expand when frozen

If anyone doubts that freeze-thaw action is powerful enough to break concrete apart just think about the damage done to a house when a water main bursts because the frozen water has split a copper pipe…..And copper is flexible; concrete is not!

Weeds as a Cause of Cracked Paths

Despite popular opinion, weeds are never the initial cause of a broken or cracked path. The crack has to be there already, however miniscule it is, for the weed to sense light and drive towards it.

Once the weeds roots are into the crack there is no stopping it other than by chemical means and these, for the most part, are rather short-lived.

The only real way of stopping weeds from damaging a path is to use a weed fabric under the path. Weed fabrics allow water to pass through them, but no light and weeds, just like all plants, need light to grow.

Weeds can be prevented in paths by laying weed fabric

Ground Movement as a Cause of Cracked Paths

The initial cause of a crack in a path, concrete or otherwise, is almost always ground movement. Notwithstanding the number of objects dropped onto paths every day, unless you are determined to break up the concrete with a sledge hammer or a kango hammer, it is very unlikely you will break a path simply by dropping things on it.

The ground under your feet is moving. Maybe only a couple of mm per year, but it is still moving, and it is moving in every conceivable direction. The tectonic plates that make up the earths structure are slipping and sliding about all the time as the earth’s core heats up and cools down.

This heat differential causes expansion and contraction in the earth, just as it does with every substance known to man. This movement then causes cracks.

Even the surface heat of the sun, when it dries the earth out quickly, causes cracks and as we have said before……If your path is not flexible enough; it will crack.

Even the ground cracks with temperature variation

Once cracked, the process starts and trust us, cracks never get smaller on their own!

How to stop Ground Movement for Paths, Drives and Patios

You can’t! The earth has a mind (and forces) of it’s own but it moves a great deal more the larger the number of materials are involved. This is called the coefficient of expansion.

Coefficient of Expansion Explained

For a rise of every degree in temperature, every material expands. They all however expand in different amounts and often in different directions. The amount each material expands in relation to the heat applied to it is called the ratio (or coefficient) of expansion.

Laying a paving slab on sand and cement, on weed fabric, on a scalping sub base

When two or more materials are placed close together, such as the sand for a paving slab path or patio base, the earth or hardcore it sits on and the concrete slab above it, they all have different coefficients of expansion and are therefore all moving at different rates in different directions.

If something stops the movement of one of these materials (EG a paving slab right up against a concrete edging stone)

Then something has to give and, in this example, it is likely to be the paving stone which may crack.

Similarly, even if the materials are the same, but one part of it is softer than another because it contains more air, or more water, then the coefficient of expansion will change for that material in each area.

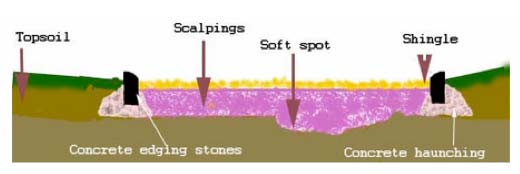

Soft spots in ground can cause paths to drop

A solution to minimising the movement, and therefore the cracks, in paths drives and patios, is what we use on British Roads.

This solution is to lay the same material, in a uniform thickness, as a sub base for the work we are to do on top. At least we then know that we have one single material which will move at a uniform rate, that is supporting all the materials above it.

It will not stop all the cracks as everything sooner or later, meets something which does not want to give way, but it will certainly minimise the cracking.

Patios and paths can be laid on a scalping sub base

Repairing Cracked Paths, Drives and Patios

We have seen, at the top of the page, where to go if you want to repair a path, drive or patio made of concrete so now we can look at how to repair other forms of path and driveway.

The rule of thumb here is that whatever the path, drive or patio is made of, do not attempt a repair with the same material unless you are in a position to replace it in it’s complete form, e.g. a concrete paving slab can be lifted out and replaced by a complete slab, or other material but it cannot be (successfully) repaired by putting more concrete into the cracks.

Use shingle to replace broken slabs

If you do not want to change the look of the path, then a complete replacement may be the only answer but we would urge you to think out of the box and try other, much more permanent methods of repair.

Using Crazy Paving as a Repair for Paths

Although not to everyones tastes, if done well, a crazy paved path can be a real focal point. They do however only really suit a certain style e.g. a more natural, “wild” layout in most situations, but then again, if done well can also fit with other styles.

Essentially, crazy paving is taking many pieces of broken bricks, paving slabs or other and laying them randomly so that they fit the area you are trying to cover.

As you might imagine, due to the different shapes, sizes etc…. involved, tis can be a time consuming job involving a lot of patience, so if you are keen to go down this path (no pun intended), be prepared for a lot of work!

Broken slabs can be used as a repair for broken slabs with crazy paving

Using Epoxy Mortars and Concretes for Repairing Paths and Slabs

There will be many occasions where an effective repair can be made to an existing broken paving slab, section of concrete or piece of block paving by simply using an epoxy mortar. Epoxy mortars are flexible, 100% waterproof and come in a range of colours.

Using epoxy mortars makes sure the repair is waterproof and long lasting

Geo Fix is a jointing compound suitable for drives, paths and patios. It will fill cracks from 5mm wide to 40mm wide and harden to a permanent finish which can even be power washed.

This compound can be bought by clicking on the image. For an even stronger hard wearing crack filler for drives and paths etc, take a look at our repairing concrete project where there are some of the best epoxy mortars on the market.

Epoxy repair mortar can be used to repair holes in paths and drives

Videos on Repairing Paths, Drives and Patios

You can also watch our several videos on the subject on our YouTube channel.

- Video on repairing shallow holes in concrete

- Video on repairing holes over 50mm deep

- Video on repairing concrete with an epoxy flow fast concrete

- Video on repairing tarmac drives with epoxy repair mortar

- Video on restoring tarmac drives to look like new

Epoxy resin pigments can be added to many epoxy mortars if you have something a little more exotic than standard concrete colours. You may also want to match the existing path, patio or driveways stones or concrete.

Tarmac drives can be repaired with epoxy resin mortars

Repairing Bricks and Blocks in a Block Paving Path or Drive

If not laid properly, or subject to gallons of water washing down the path, block paving can sink. If it does, it looks terrible as this image from The Paving Directory shows.

Sunken bricks look unsightly in paved paths

Brick or block paving is laid on a compacted sand base but if that base is not compacted by the same amount, throughout the path, a crack can develop as one or more of the blocks or bricks sinks.

In the image shown below, the block paving is laid right up to the edgings stones. These edging stones have a concrete haunching to keep them in place. If the sand, over the haunching, is not deep enough, the block paving will sink down onto the haunching where it cannot move any further. It’s flexibility is lost and as soon as a car drives over it, it has no-where left to go so it may crack.

Some sort of edging usually surrounds block paving

If a block or brick breaks they are hard to get out on a singular basis and levering them out with a crowbar, screwdriver or even chisel is sometimes the only option. When it is out make sure the base is level underneath and judge how much the brick will sink when you compact it down.

Finished block paving path with joints being filled

Take a look at our project on block paving for more on this subject.

Removing a Difficult Single Paving Brick From a Brick or Block Paved Path

If you cannot lever out the offending paving brick with the tools suggested you may only have one option left and that is to remove it as you would remove a single brick from a brick wall or a single tile from a bathroom wall.

Paving bricks can be removed in the same way as wall bricks

Drill a series of holes in the brick with a good drill and a 7mm masonry bit. When the brick is weak enough you can hit it with a hammer and chisel to break it up. It can then be pulled out piece by piece.

Compacting a Replacement Brick in a Block Paving Path

It would be costly to go and hire a compaction tool or whacker plate just for one brick so we suggest you get a short length of solid timber, say 4 x 4 inch or 100 x 100mm.

Place the brick in the hole and lay the timber on top of it. Hit the timber to force the brick down, compacting the sand at the same time. Then replace the fine (silver) sand in the joints.

Repairing Tarmac Paths and Drives

Tarmac round gullies is often poorly compacted

Tarmac holes and splits develop, more often than not, as a result of the drive or path not being prepared or laid properly. The sensitive areas are around gullies and against edging stones where the tarmac layer was too scared, or could not be bothered, to compact the Tarmac properly.

It is possible to buy bags of "cold lay" tarmac for these repairs and if you choose to do this (DIY Doctor does not recommend doing this) then the new tarmac must be rammed very very hard into the hole.

The proper tool for this is called an earth rammer.

An earth rammer should be used to compact the Tarmac as much as possible

The reason we do not like to do this is because the new tarmac does not mesh into the old. This leaves fissure through which the dreaded weeds may grow regardless of how hard you ram it!

We prefer to use an epoxy compound which is superb. Its thin aggregate allows the mortar to mesh into the old tarmac and perform repairs which will last longer than the driveway or path itself.

You can see how effective this tarmac repair method is by looking at the images on this page and clicking through to the video.

There is a link to a video above and if you click here you can see a product review of this tarmac repair compound being used. The video is available on this page also.

Tarmac round driveway drain gullies can be repaired with epoxy mortar