As visually appealing as timber can be when used in construction, unfortunately it never tends to last as long as many other materials and over time it can become weak and damaged.

When this happens it either needs to be repaired or replaced so in this guide we look at the options available for repairing structural timbers.

Why do Timbers Need Repairing?

There are various reasons why timber may need to be replaced or in this case repaired but some of the most common are due to time itself, overload often associated with alterations, insect damage and dry or wet rot.

In respect to time, although in some particularly old buildings such as the many tythe barns dotted around the country, period houses etc. there are some extremely old timbers, some many hundreds of years old, time can it’s toll to the point that they need repair.

As many modern timbers are nowhere near as strong as ancient timbers, mostly down to the way they are grown, surprisingly many of these can also require repair.

When it comes to overload, as you may imagine this is applying too much weight for the size and strength of timber to carry.

As a good example of this is a roof truss. When installed the truss may have been designed to carry the weight of simple slates, but over the years these may have been replaced by heavier concrete tiles which can then cause a truss or trusses to buckle under the weight.

As you may imagine, insect damage generally comes from one of the many wood boring insects and beetles that we get in the UK such as Woodworm, Longhorm Beetles and the likes.

Finally comes dry rot and wet rot. When timbers are exposed to certain mould, fungi and moisture for extended periods it can cause it to rot and become structurally unsafe. When this happens the only option is repair or replacement.

Types of Damage to Structural Timbers

To go a little further on the above, now would be a good time to look a little more into the various types of damage that can occur to structural timbers and indeed any other type of timber.

Load Stress (splits, bending, deflection)

Load stress damage can occur to a timber when it is subjected to more weight than it is able to support. When this happens, if it doesn’t break right away, over time the weight will cause it to bow and sag.

A good example of this is a ceiling joist – when a ceiling joist is installed, if there is a floor above it then it must be the correct size to support the weight of everything above it. If it isn’t then it will bow and sag due to this, and can even snap!

Broken roof joist due to too much weight

Wet and Dry Rot

Damp, mould and certain fungi’s are an absolute nightmare for any type of timber.

When exposed to damp and wet conditions for extended periods of time, any timber, even if it’s been treated, will eventually rot as the moisture weakens the fibres of the wood and it eventually loses all of it’s strength.

Moisture exposure can also bring with it moulds and fungus, as many of these favour dark moist conditions in order to grow. Once they establish themselves they can accelerate the decay process causing the timbers to fail even quicker. Find out more about wet rot here.

When it comes to dry rot, the name is a little misleading as it also requires moisture for it to establish itself and once it does and gets to the strand-stage, it can travel across multiple surfaces and infect timber over a wide-spread area.

Once infected it will eventually cause timbers to crack and crumble to dust! For more help with dry rot, see our project here.

Dry rot damage to timber

Insect Attack

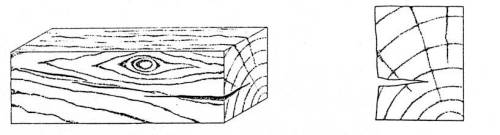

In a similar way to dry and wet rot, insect attack from woodworm and other beetles can significantly damage and weaken any timbers.

As these pests bore down into the timbers, they can many channels through the body of the wood itself. Although very tiny, as they increase in number this can drastically decrease the strength of any timbers significantly.

To learn more about woodworm damage in timber, see our project here.

Damage to timber caused by woodworm

Splits and Cracks

Although you may imagine that any type of split or crack in a structural timber is extremely worrying, in some instances this is not the case.

Some cracks in timber beams need not affect the overall integrity of the structure. Indeed, some can be taken as a positive visual feature of the timber, which, in conjunction with the timber grain, distinguish them from the more uniform man-made materials such as steel and concrete.

The integrity of the timber can be called into question when it is impaired by cracks, splits and shakes and often in this instance will required the replacement of a beam or rafter which has formed part of the original structure.

In many cases there will be visual signs that the timber is structurally compromised such as large splits or cracks running over a good proportion of the surface or even in extremes, the fact that it’s snapped!

Cracks, shakes, warps and fissures are formed as a result of the timber giving up moisture and shrinking.

This may occur as part of initial drying or subsequent changes, during service, in the Equilibrium Moisture Content. The EMC of timbers inside buildings can range from 9% to 14%. Fibre saturation is reached in constructional softwoods at about 28%.

Snapped reinforcing timber in roof – Image courtesy of hometalk.com

Spreading

Spreading occurs mainly in roofing timbers or those that carry large weights such as floor joists and in pretty much all cases is due to too much weight.

As you may or may not know, a roof truss is designed so that the load imposed down on to it by the weight of any coverings such as sheet timber, tiles etc. is then transferred down on to the wall plate and in turn down to the foundations.

When too much weight is applied, the additional load that isn’t transferred down to the foundation starts to crush the truss itself causing the ends to splay outwards.

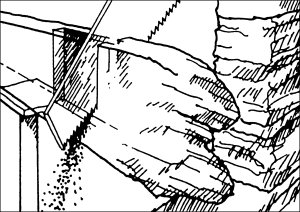

Joist Ends

Failure of joist ends is often due to moisture and rot and in some cases also insect attack.

To support a truss, rafter or joist, it’s ends sit on top of the wall plate. Over time, water and moisture can penetrate up through the masonry of the wall plate, down through the roof or indeed from many other locations and as we have discussed above, when timber is exposed to moisture, especially if it’s not treated, this can cause rot and fungi and mould damage.

When this happens, they lose their strength and ability to support the weight of the truss and in turn the weight it supports. In extreme situations it can then also collapse!

Timber Treatment

When using any timber in construction, ideally you should be using treated timber. Although as we have stated, this will itself decay and rot in time, it will resist any moisture damage much, much longer than untreated timber will.

That being said, if you are constructing simple stud walls or the like, treated timber would be a little overkill, but when dealing with roofs or any similar structural items, there should be no exceptions.

In some instances, additional treatment is also often a good idea and this can be in the form of applying a proprietary timber treatment solution such as Cuprinol 5 Star Wood Treatment to the timber yourself or, in the case of joist ends that will be set into masonry, a good covering of bitumen or a tar-based coating.

In terms of what types of timbers can be used when treated timber is required, this is specified by the British Standard BS EN 335-1. In brief, this document states the 4 different classes of timber use and where each applies:

- Class 1: Dry conditions and internal use, stud walls etc.

- Class 2: Dry conditions but the chance of moisture expose, floating ground floor joists, bathrooms

- Class 3: Wet exposure but not touching the ground, decking timbers and the similar

- Class 4: Wet exposure and direct ground contact, e.g. fence posts

Traditional Timber Repair Methods

Repairing structural timber has always been an expensive and time-consuming operation. From a timber lintel in a Georgian terrace, to a huge tie beam in a barn conversion, if a new section cannot be spliced in or bolted on, there is then no choice but to remove the old one and replace it with a new one.

Very often, even if it were possible to bolt a new section of timber on to re-strengthen it, the overlap for the bolts would be so long you would have to pretty much replace the entire piece anyway.

Removing complete timbers or carrying out traditional splices in joists, rafters and other structural timbers requires considerable opening up of ceilings, floors and roofs, and most people would rather not take their houses apart.

Due to the levels of work involved, the time scales are often equally as eye watering.

In most cases, complete replacement of any timbers, especially roofing timbers will be impossible by traditional means without the need of scaffolding or roof removal and the costs and stress involved.

Today, to help negate all of these associated hassles, many new products and techniques have been developed, which leads us nicely into some of these listed below.

Modern Timber Repair Methods

As you will now be aware of some of the different types of damage that can occur with both structural and non-structural timbers, it’s now time to take a look at some of the methods of repair.

When it comes to repair, many of the issues outlined above can be remedied using only a few different methods, the most common of these we have detailed below.

Epoxy Fillers and Mortar – Splits, Cracks, Holes

Non-structural splits, cracks and holes can now be fairly easily delt with using an epoxy filler or mortar or putty as it’s also known.

For cracks and splits that are greater than 5mm wide the void can be filled with a mouldable epoxy mortar, but if the crack penetrates more than 30% through the timber it will be necessary to install dowels or epoxy-glass bars across the filled section in order to ‘stitch’ the two halves together.

The advice of a Structural Engineer should be taken with regards to the number, diameter, length and spacing of the dowels to ensure any required strength is maintained.

The dowels can be made of glass fibre, carbon fibre, steel or stainless steel. We recommend the use of epoxy/glass or epoxy coated steel that is then set in an an epoxy resin.

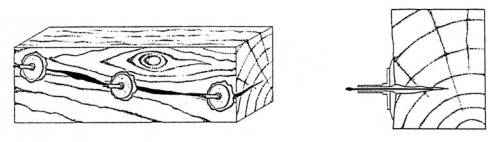

Splits in timber section

The steps involved in install are as follows:

- Step 1 – Clean Cracks/Splits and Fill: Clean out cracks or splits with a saw blade and vacuum out all sawdust. Fill the cracks with Mouldable Epoxy Mortar

- Step 2 – Drill Holes: When the mortar has set, drill small holes, about 6mm in diameter through the epoxy into the back of the crack. Blow, or vacuum out the dust

- Step 3 – Inject Epoxy: Directly inject your chosen epoxy injection resin into the hole, until the resin flows from the adjacent hole. Continue until all the holes have been injected and cap off each with mouldable epoxy mortar

- Step 4 – Finish up: Sand off any excess mortar and colour finish to suit the timber. If stitching is then required, the cracked areas can now be cross-drilled and epoxy-glass or steel rods fitted in an epoxy resin

Timber splits repaired using epoxy injection and mouldable epoxy mortar

Structural Epoxy Resin and Reinforcing Bars – Splits and Cracks, Strengthening, Rot, Insect Damage

In a similar vein to the above, when you are needing to repair structural timbers with large splits and cracks, heavy warping or bowing or those that have snapped, then something a little more substantial is often needed and this comes in the form of structural pouring epoxy and reinforcing bars.

This repair, in most instances, relies on the fact that there will be some of the timber remaining that can still be used as the reinforcing bars need to be set into the existing timber and the epoxy poured around them.

As such, it’s generally used for large timbers with rot or damage that still poses enough body to work with.

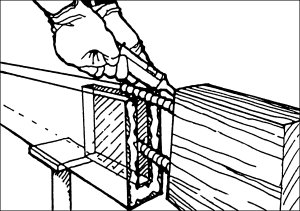

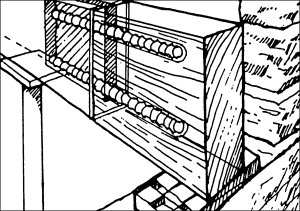

The basic steps involved in such a repair are as follows:

- Step 1 – Remove Damage: Using a suitable grinder, saw, drill, chisel or similar, remove all loose and damaged timber and then vacuum away any remaining items and dust

- Step 2 – Cut Slots: Using a suitable tool, cut a slot or slots into the timber and then clean away any dust

- Step 3 – Insert Reinforcing Bars: Insert the reinforcing bars down into slots or channels, spacing them apart suitably

- Step 4 – Mix Resin: Following the manufacturer’s instructions, mix the resin up in a suitable bucket

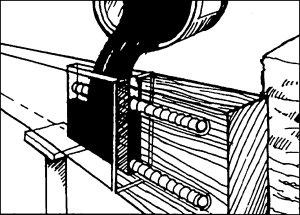

- Step 5 – Pour Resin: Once mixed, pour the resin down into the channel or channels, covering the reinforcing bars. It should level itself at the top

- Step 6 – Finish Up: Once the resin has fully cured, if necessary, it can then be sanded off flat

Reinforcing bars set into timber

Pour resin into channel in timber

Finished and sanded off resin

If you would like to know a little more in-depth information on this technique and how it can be used for repairing a variety of different types of timber damage, see our repairing structural timbers project here.

Timber Splicing

Timber splicing is an extremely useful method of repairing a variety of timbers while they still remain in place, everything from joist ends to fairly long lengths of timber can be replaced with new without the hassle of having to remove the entire piece, which as we’ve discussed can lead to a huge amount of work and expense.

Using a timber-resin splice system a damaged section of timber can be cut out in situ and a new section added. In actuality the repair will be stronger than the original.

It really is an uncomplicated breakthrough allowing new, treated timbers to be installed with the minimum of fuss and disturbance.

Decayed timber joist replaced with timber resin splice

Timbers are not all accessible from the same place. While you may be able to get to a floor joist from the top by lifting a section of the floor, it is far easier to access a rafter from underneath.

In the below sequence of images we have shown one of the most basic jobs, repairing a floor joist that is accessible from first floor level. We are working in a first floor bedroom with a lathe and plaster ceiling.

For the benefit of this project we have simplified the procedure…But not by much!

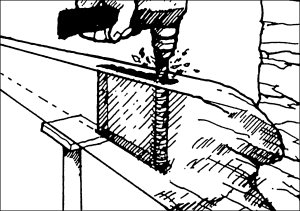

- Step 1 – Cut Slot in Joist: The first job is to access the joist and drill a slot down into the good section of remaining timber, ensuring there’s enough solid material for a good fix

- Step 2 – Remove Rotten Timber: Once the slot has been cut, cut off the rotten/damaged timber at the end of the slot so that once removed the end of the slot is opened up. Make sure your cut is absolutely square

- Step 3 – Fix new Section in Place: First, if the timber is being set into a wall, it’s a good idea to treat it with a bitumen-based coating to protect the new section of timber. Next, apply quick setting paste to the end of each section of joist and then position the new section in place, ensuring the reinforcing rods are set down into the cut channel and then the whole lot is then set back into the wall

- Step 4 – Pour in Resin: Once all set and positioned, the epoxy resin is then mixed up and poured into the channel, ensuring there are no gaps or air pockets. It is then left to fully cure

- Step 5 – Finish up: Once the resin has fully hardened off it can then be sanded off flat if needed. Once completed, all can then be put back together, and the joist end cemented in place if required

Rotten joist in wall with slots being drilled in good part of the timber

Rotten end of joist cut off

New joist section fixed in place and reinforcing rods positioned

Newly created joist then set back into place in the wall

Resin poured into slots in existing timber securing rods in place and securing the two sections joist together

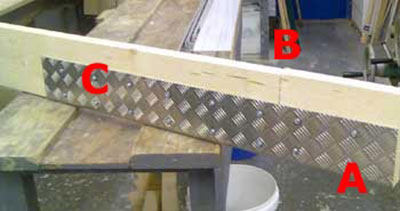

It’s also worth mentioning that there is another method of splicing that uses joist support plates instead of resin and reinforcing bars.

The joist support plates are essentially a pair of L-shape brackets that sit over either side a timber.

Once the damaged section has been cut away, the new section is positioned at its end and then the brackets are screwed either side of both pieces, securing them together

This method is in a way even easier than using the resin, however it is very obvious and in some cases this may be an absolute no-no, especially if working on a period building!

To find out more about theis technique, see our repairing structural timbers project here.

joist repair plates or brackets used to repair damaged or rotten timber

Load Stress, Strengthening and Spreading

When it comes to structural timber damage caused by load stress or spreading, the results of such should be visually obvious.

As mentioned above, load stress will probably appear in the form bending, cracked or even broken timbers and spreading will appear as sagging in parts or whole of the roof and also again possibly sagging etc.

When it comes to a fixing method, this will normally be one of the following:

- larger Timbers: To add strength, the first port of call may be to replace the compromised timber with a more substantial one that is capable of supporting the load. This would need to be calculated by a structural engineer and would involve a fair amount of work to install

- Doubling Up Timbers: A slightly quicker method instead of replacement is to double up and add new timbers that are bolted and fixed along the length of the damaged timber to provide more strength. Installation is generally much simpler, however it’s not suitable in all circumstances

- Tie Beams: In the case of spreading, especially with roof trusses, generally a tie beam is added. This is a timber that runs between 2 joists at the base to form a triangle shape, giving it a huge amount more supporting strength

Important Note: We recommend seeking the advice of a structural engineer when it comes to these types of structural repairs! You should not attempt anything until a structural engineer has produced a clear plan that details exactly what technique should be followed, what type of materials should be used and what building regulations or BS standards need to be met!

Once this has been done, it should be more than possible for any repair of this nature to be successfully carried out.