Soundproofing is a specialised field, and finding capable companies can be challenging. We’ve partnered with Custom Audio Designs for this project to provide insights from industry experts, for tips and pointers that do actually work.

Noise regulation is governed by Part E of the Building Regulations, which must be followed diligently throughout your soundproofing endeavour.

Understanding Sound Transmission: How Sound Moves through Surfaces

Sound is a form of energy. The more energy created in one place, the greater its impact elsewhere if allowed to travel.

Think of it like firing a pea from a catapult: the more force applied, the stronger the impact. Similarly, the louder the noise, the more noticeable it is where it’s heard.

To mitigate the impact:

- Use thick or dense materials to absorb and reflect the energy, reducing its impact. Closing doors can help.

- Soft materials absorb the energy, lessening its effect. This is like putting your head under a pillow to muffle sound.

- Prevent the source of the noise, just like removing the person with the catapult.

Sound varies in frequency, so addressing different types requires tailored approaches. Just as different peashooter sizes have different impacts, various sound frequencies require specific solutions to protect against them.

Soundproof Barriers and Passive Absorption Soundproofing

There are two main sound control options although they come with many variations:

Passive Sound Absorption Techniques

When sound encounters materials designed to absorb it, like mineral wool insulation or acoustic foam, it doesn’t pass through easily. Instead, it’s forced to change direction multiple times, traveling along the material’s fibres. These materials, known as “acoustic absorbers”, and each time they cause a sound wave to change direction, a part of that energy is absorbed and converted to a small amount of heat.

Low-frequency sounds, such as bass, travel farther because they can navigate around obstacles more easily. That’s why you can hear thunder from miles away. Similarly, at music festivals, bass noises carry further, thanks to their larger wave amplitudes.

Sound Barrier Basics

When sound encounters an absorber with a reflective surface behind it, like a wall, some of the sound energy passes through the absorber and reflects back. This process repeats, enhancing the absorber’s effectiveness. For low-frequency sounds, an air gap between the absorber and the wall works best.

Low-frequency sounds, while traveling at the same speed as high-frequency sounds, can’t penetrate absorptive layers as easily due to their lower energy.

To construct a noise barrier, use any dense, non-porous material. The barrier must have sufficient mass and a low resonant frequency to block or reflect sound energy rather than vibrating along with it. As sound pressure levels rise, so does the sound power, causing surfaces to vibrate.

Low-frequency sounds contain more energy due to the displacement of a larger volume of air, especially evident in bass and sub-bass frequencies. These low-frequency sounds readily excite common building materials, like wood and standard 12.5mm thick plasterboard.

Dealing with Noise as a Tenant or Landlord

Are noisy neighbours or traffic noise disrupting your peace? If you’re a tenant in a semi-detached house, bungalow, or flat, you can find assistance for soundproofing and noise pollution issues at Landlordzone.

For more insights into soundproofing and noise control, this Wikipedia page offers comprehensive information on the topic.

General Soundproofing Tips for the Home

Before we go into more involved solutions, we will first start with a run down on some general tips and tricks for sound proofing in and around teh home:

- For any water hammer issues e.g. banging in pipework, remove any airlocks or fit a water hammer arrester

- Ensure all pipes are fixed to a solid surface using suitable pipe clips

- Consider replacing aluminium air ducting with PVC (less reverberation from fans and teh likes)

- Consider spending a little more on quieter appliances

- Isolate any appliances such as fridges, dishwashers, washing machines etc. from teh floor by placing them on thick rubber pads

- Use thick, heavy curtain or drapes to cover windows and doors close to sources of noise

- Use dense curtains, carpets and furniture to absorb sounds in noisy rooms

- Use a suitable flexible filler to fill any gaps in external walls, around windows, doors, waste pipes etc.

- If your budget allows, install double or even tripple glazed windows and doors

- Install gap filling strips on any doors or windows who’s seals have worn to teh point they no longer seal sufficiently

- If your property is next top a busy road, industrial estate or similar, consider installing large, thick fencing or growth tall, thick trees or hedges

- Consider adding additional stud walling using sond proof plaster boards and sheet insulation to the interior surfaces of rooms that abut busy roads and other exterior noise sources

- If you have sash windows, consider filling any and all gaps using sash windows gap filling strips

By undertaking and dealing with as many of the points above as you possible can, will in most cases, reduce a considerable amount of both external and internal noise and any noise leaving you with a much quieter home. However, any remaining noise will likely require some further considerable work to resolve.

Home Soundproofing Solutions

For improving soundproofing in existing structures, a common approach involves adding acoustic boards or layers to dampen, reflect, or absorb sound waves. We’ve categorised soundproofing into several main areas and outlined methods to address specific issues in each scenario, including the use of acoustic membranes and other techniques.

Soundproofing Solid Walls

To minimise sound transmission through solid walls, which already possess substantial mass, the key is to increase the mass further. Sound encounters greater difficulty traveling through densely packed materials, which effectively dampens the sound. While covering walls with lead sheets would be effective, it’s impractical due to cost and decoration challenges and health risks.

Enhancing solid walls with dense layers significantly reduces sound, and various dense plasterboard and acoustic boards available in the market serve this purpose well.

Soundproofing Hollow, Stud, and Plasterboard Walls

Sound encounters a hollow or stud wall, traveling across the top layer (plasterboard), vibrating the fixings that attach it to the studs or timbers within the wall. To enhance soundproofing, one would ideally add an acoustic layer, like mineral wool, inside the wall to absorb sound. Decoupling the plasterboard from the studs helps prevent vibration from transmitting through the wall.

If you’re constructing your own partition stud and plasterboard wall, you can incorporate soundproofing measures mentioned on this page.

Decoupling can be achieved by using resilient bars fixed onto the studs, isolating the plasterboard from direct contact with the studs. Resilient bars, also known as resilient channels, effectively isolate plasterboard from the stud-work, reducing sound transmission. However, decoupling may lead to resonance issues, which can be mitigated by using an acoustic absorber inside the wall void.

Alternatively, mass loaded barriers, typically made of vinyl, can be affixed to existing stud walls to dampen sound. Acoustic plasterboard sheets can also be installed over existing walls to create additional sound barriers. Combining a mass loaded barrier between two sheets of acoustic plasterboard enhances soundproofing effectiveness.

Soundproofing hollow walls, such as stud walls, can be challenging, often requiring the integration of multiple techniques for effective isolation.

Self-adhesive mass-loaded dense barriers can be easily installed.

Acoustic plasterboard or Soundbloc™ boards, identifiable by their blue colour and higher density than regular plasterboard, are available in 12.5mm or 15mm thickness from most builders merchants.

How to Soundproof Ceilings

Most ceilings are constructed similarly to hollow or plasterboard stud walls, transmitting sound in a comparable manner. Sound from above transfers through the ceiling, making decoupling an effective method to prevent sound transmission. Utilising resilient bars and packing mineral wool insulation into the void can enhance soundproofing. Ensure to encase electrical cables in conduit to prevent overheating.

Mass loaded barriers and soundproofing mats, typically 2mm thick and made of dense materials, can be affixed to the ceiling. These mats absorb sound upon impact, offering additional soundproofing. Consider incorporating soundproofing techniques when changing the ceiling surface to Soundbloc plasterboard or directly onto an existing ceiling.

Soundbloc plasterboard features a higher density, aerated gypsum core.

If you have access to the floor above, refer to the section on soundproofing floors to optimise the entire ceiling and floor construction for soundproofing.

How to Soundproof Floors

Soundproofing floors aims to block airborne noise from below. If feasible, removing and relaying floorboards allows for the addition of acoustic quilt or mineral wool, reducing noise significantly. Filling floorboard gaps helps with drafts but is less effective for soundproofing.

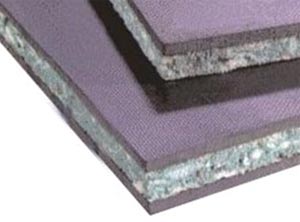

A composite acoustic quilt offers superior performance by combining fibreglass absorption with a dense membrane to block sound. Acoustic mineral wool effectively absorbs sound, especially between flooring joists and ceilings.

An efficient solution is a carpet underlay like Quietfloor, reducing impact and airborne noise. It’s easy to install and cost-effective, complementing acoustic wool in the floor void. Quietfloor comprises dense acoustic foam covered by a 2mm mass load barrier.

Quietfloor floor insulation

How to Soundproof a Workshop, Music Room, or Recording Studio

To diminish noise in highly intrusive environments like workshops or children’s bedrooms, utilise specialised acoustic foam tiles. These tiles, generally made of CNC-cut 25kg/m3 high-density foam, possess an open-cell structure for optimal acoustic performance.

Acoustic foam tiles effectively reduce noise in loud rooms

How to Reduce Sound Travel in Pipes, Cables, and Heating Ducts

Install baffles or diffusers in unused air-bricks and chimney flues to allow air passage while minimising noise reflection or dispersion.

Use acoustic pipe insulation wraps to dampen sound transmission along long pipes and ducts. Noisy pipe and duct systems, including macerator systems like Saniflo pumps, can create disruptive noise throughout the house. Additionally, soil and vent systems may produce noise from flushing chains and gurgling basin wastes. Dense insulation coverings effectively mitigate these issues.

Consider using foil-faced Acoustic Pipe Wrap for various applications, including noisy pipes, pumps, engines, enclosures, Saniflow systems, and soil pipes.

Decouple vents and ducts from their connected surfaces and insert dense washers, possibly made from materials like dense foam, to further reduce noise transmission.

Soundproofing Materials and Products

There are a range of materials suited for soundproofing, many that we have already mentioned, but here are the most common that are used. There are specific characteristics and uses for these various products, which are explained in more detail here:

Advanced Acoustic Membrane

This 2kg high-performance acoustic membrane surpasses lead sheets in sound-blocking capabilities. With a 22dB rating and a thickness of just 1.2mm, it’s easy to handle, cut, and install.

Generally available from most acoustic control supply stores and companies online.

Acoustic membrane – Image courtesy of controlnoise.com

Advanced Acoustic Quilt

Advanced acoustic quilt offers superior performance compared to standard cavity infill products. It combines acoustic fibreglass absorption with acoustic membrane to effectively block sound.

High performance acoustic quilt

Acoustic Mineral Wool

Acoustic mineral wool is an excellent sound-absorbing material, ideal for reducing airborne noise behind partition walls, between flooring joists, and in suspended ceilings. Its high density makes it significantly more effective at absorbing sound compared to standard loft insulation. While standard fibreglass loft insulation typically has a density of around 20 Kg/m³, acoustic mineral wool ranges from 100 to 140 Kg/m³.

High Performance Acoustic Wool – Image courtesy of soundproofingstore.co.uk

Quietfloor Underlay

Quietfloor is a specially designed carpet underlay system that reduces both impact and airborne noise transmission through floors. Its laminated composition offers maximum performance with minimal thickness, combining excellent sound insulation with typical carpet underlay qualities. With a thickness of just 12mm, it minimizes the increase in floor level and is easy to install, cut, and shape. This product can be fitted by homeowners themselves, making it a convenient solution for noise reduction.

Quietfloor Underlay System

Resilient Bar Isolation System

A resilient bar is a thin metal channel designed to significantly enhance the sound insulation of plasterboard walls and ceilings. By isolating the plasterboard from the stud-work, it prevents direct contact and reduces the transfer of sound through the frame. This system is easy to install and delivers excellent results, particularly when combined with suspended high mass ceilings.

Resilient Bar Isolation System

Soundproofing Mats

Soundproofing mats are engineered to diminish airborne noise transmission through lightweight floor and wall structures. At only 2mm thick, they outperform lead in blocking sound.

Soundproof Matting

Living with constant noise disturbance when you are trying to relax at home is both annoying and can be extremely detrimental to your health long term. With a little knowledge and a basic budget, it is possible to resolve many domestic noise issues if you know now, so use our tips and guidelines above to make your home life much more bearable.