If your ground floor timber floors have become infested with insect damage or dry rot you might choose to replace them with concrete floors.

However laying a concrete floor to replace your timber floors may not be the end of your troubles if you don’t take care to treat the problem before you lay a concrete slab for your new floor.

Dry rot can spread through and over most building materials, including masonry and concrete, once it is established so it is really important to treat it thoroughly before you replace your floor.

These points all need consideration before you lay a new concrete floor in your home:

- Dry rot in the original timber floor must be properly treated or it may re-emerge at the edges of the new concrete, causing expensive and extensive damage to skirting boards and other joinery. Dry rot can spread out into dry areas, so great care must be taken to remove ALL debris before filling the void under the old timber floor to raise the level with rubble and hardcore. Rake any soil thoroughly for timber chippings. The soil must be sterilised correctly to kill off any remaining spores or fungus. Tips to do so can be found here.

- Hardcore rubble and brick, brought in to fill up the old floor void, may also be contaminated with Dry rot, so be sure to also treat this thoroughly in the same manner as the soil

- The original wall damp proof course (DPC) was designed to protect the timbers, skirting boards and plaster from rising damp. The damp proof course is usually made from black bitumen, slate or plastic, and should be should be visible below the timber joists. By laying a concrete slab you may alter the original level of the floor and bury the DPC. You will in effect cause a bridge between the ground and the wall by doing this and in fact we use the term ‘bridged’ when describing this effect. If your new concrete floor bridges your existing DPC you may need to inject a new damp proof course at the correct level, and we explain how to do that in Damp Proof Injection Project Page

- Unless you live in a detached property your new floor may also ‘bridge’ your neighbour’s damp proof course in the Party Wall, causing their wall to suffer from rising damp. Under the Party Wall Act you MUST ask your neighbour for permission before doing any work that might affect the Party Wall. Check the position of the DPC and the relative ground levels of your two properties. If there is a problem with the level of your new floor in relation to your neighbours DPC you may need to consider tanking the wall to prevent lateral penetration of damp between the two properties. In our experience neighbours are frequently involved in expensive legal actions when this Law is ignored, so please seek expert advice before you start work

- Most new concrete floors are laid well, BUT even the best builders can forget to seal the floor to wall joint properly. This leaves a small gap between the wall face and the plastic DPC sheet that rises up the wall from under the new concrete. This becomes a high pressure area for water vapour. Even if a damp proof course has been correctly fitted, if the gap is not prepared and sealed properly, damp can be drawn up the wall and the vapour alone can cause rot in the skirting boards and ‘salting’ in the plaster above. This can be avoided by sealing the gap with an epoxy grout.

- Pipes and other services may pass through the original void – gas, water, electricity, sewage etc. You should consult a professional before burying any service pipes or wires, most require ducts to be laid and specific safety regulations apply. You will also need to seal around the pipes or ducting to prevent moisture build up

- If you are laying a concrete floor following extensive insect damage you should ensure that all remaining timbers and skirting are thoroughly treated before you pour your concrete floor, to eliminate the chance of further infestation in other parts of the house

Dry rot present on timber joists

Epoxy pouring resin used to fill gaps

How to Lay a Concrete Slab in Place of a Timber Floor

If you have decided to lay a concrete floor yourself there are some points you need to know. The floor construction of a house, or dwelling, must fulfill several criteria, and the following design functions must be taken into consideration when laying your concrete slab.

Your floor must comply with the following:

- You must provide a uniform, level surface

- It must be sufficiently strong and stable

- You must exclude damp from coming inside the building

- Thermal insulation must be added to current regulations

- It should be resistant to fire

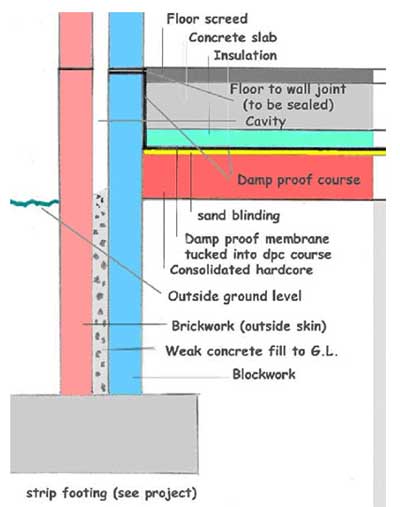

We have provided a sketch below to show the most common form of concrete floor slab construction. However it will not be applicable in every case.

Speak to the Building Control officer of your local Council for instruction and to obtain the necessary Building Regulation approval before you start any work.

You may also need to apply for Planning Permission, if you are constructing a new building. We go into this in more detail in our Planning Permission project.

Cross section of how to construct a concrete floor slab

Where we indicate insulation on the drawing, we should point out that this must be to the specification shown by the architect, if it is required.

All hardcore should be compacted to refusal, that is to the point where is will not compact any further – this should be done using a mechanical compacter or whacker plate as they are known.

Next, place a layer of sand blinding on top of the compacted hardcore to avoid puncturing the Damp Proof Course. As previously mentioned any pipework or cables placed in the screed must be accessible through proprietary ducts with removable covers.

When it comes to the actual thickness and construction of the foundation you may find it helpful to visit our Foundations Project for a fuller understanding.

Basically the foundation sizes and depths for local authority approval is the entire thickness of all the layers: hardcore, concrete, insulation and screed, together with the gauge of the damp proof membrane.

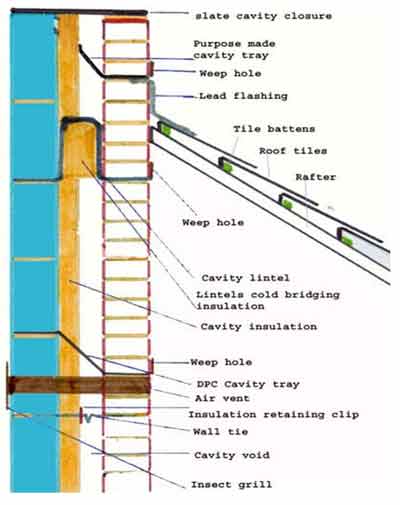

If you have Cavity walls then bear in mind that a new concrete floor could bridge the cavity at doorways where the floor screed meets up with a door frame. You can find out more in our Cavity Walls Project about how to deal with this.

Cavity wall cross section

Repairing a Concrete Floor

Concrete floors are very durable and are relatively maintenance free during their long life. However if there were any problems with the original laying of the base it is possible that, if you have an existing concrete floor, it may need some repair or maintenance after it has been down for a period of time.

Concrete Floor Problems

Concrete floors suffer from four main defects:

- Open joints between the edge of the slab and the walls – This can cause floor-to-wall damp, resulting in damp patches, wet and dry rot in skirting boards, and ‘salting’ in plaster

- Cracks – these can occur due to subsidence, a poor or unstable foundation, or they may be a symptom of rapid drying when the concrete was poured.

- Holes and voids – this can be caused if the concrete is not poured correctly or again by a poor or uneven foundation. It can result in localised damp patches, hollow spots and in severe cases collapse

- Punctured Plastic or Liquid Membranes – usually caused by a poor foundation where rubble has not been properly compacted and levelled and then a blinding sand laid to protect the DPC form puncturing. This can cause damp patches, and lifting of floor tiles and other coverings

- Lack of DPC membrane – If the foundations were not covered with a damp proof membrane before the concrete slab was poured then this can cause moisture to leach up into the floor from the ground. This can cause damp patches, overall dampness, which in turn will damage floor coverings by lifting floor tiles and laminates, and causing fungal and mould growth under floor coverings such as vinyl, lino and carpet

Causes of Damp Patches on Concrete Floors

If you see damp patches forming on your concrete floor you must make sure you check out the possibility that you have a water leak, above or below the floor. The possibility of a leak MUST be eliminated before you attempt to carry out a repair.

If you don’t you could cause a problem in an adjacent area (See our Checklist). If the damp is caused by a water leak e.g. from a leaking radiator pipe, it will be much more easily fixed than a punctured DPC.

Cracked and broken concrete floor

If cracks, holes or voids have developed you should consult a Structural Engineer to establish the cause. If they recommend that you make repairs then the remedy depends on the problem with the floor, here is a guide to the best way to deal with damaged concrete floors:

- Open floor to wall joints – these should be opened up to a slot at least 1 inch x 1 inch (25mm x 25mm) by cutting a slot at the floor edge, in the slab surface, without damaging the plastic membrane. Clean the slot thoroughly to remove all dust and debris and then fill with a special Structural Epoxy Pouring Grout (available from most DIY stores)

- Cracks – these should be opened up to slots at least 1 inch x 1 inch (25mm x 25mm), using a disc cutter or grinder, but without penetrating deeply enough to reach the membrane. These slots are then cleaned thoroughly to remove all dust and debris and then should be filled with a special Structural Epoxy Pouring Grout, see link above

- Holes and voids – excavate to the full depth of the defect carefully. If you reach as far down as the waterproof membrane layer then extend the hole laterally to expose enough sound membrane to be able to effect a repair. This should be at least 150mm (6 inches) from the edge of the hole. Remove all dust and debris from around the area. The hole can then be repaired, either using Structural Epoxy Pouring Grout (as mentioned above), or for holes larger than 8 litres in capacity, a combination of the Epoxy Grout as a base layer and concrete as a filler. The final surface can then be covered with levelling floor screed, however you could also add some SBR into this mix as this will avoid shrinkage and cracking of the floor and help with bonding

- Punctured Membranes – remove all floor coverings to expose bare concrete, and then run a Dehumidifier until the damp recedes to defined areas, and does not reduce any further. This drying time can takes a number of weeks depending on weather conditions, temperature in the room and the amount of moisture the concrete has absorbed. When you have defined damp patches, mark the areas with chalk and excavate them carefully to expose the defective membrane punctures. The hole can then be repaired in a similar way to holes above, either by using Structural Epoxy Pouring Grout, or as above if the holes are larger than 8 litres in capacity, use a combination of the Grout as a base layer, and concrete as a filler. As previously mentioned the final surface can be screeded, but use a little SBR in with the mix to avoid shrinking and cracking of the repaired areas

- Lack of Membrane – To be sure there is no membrane you should first remove all floor coverings to expose bare concrete and then run a Dehumidifier until the damp completely disappears. If damp patches remain see (4) above. If not, you can clean the floor to remove all contamination (hot wash with detergent, and then thoroughly rinse), then repair any defects. Seal the floor to wall joint as in (1) above and then apply two coats of an Epoxy Sealer (purchased online or from your lcal DIY store). If you intend to lay flooring that requires an adhesive then check with the manufacturer for bonding details – you may need to sand ‘blind’ the second coat of Epoxy Seal to provide a mechanical grip

Causes of Dry Rot and Insect Attack

Many buildings with suspended timber floor suffer from rot and insect attack in the ground floor timbers due to poor sub floor ventilation. We look at this more thoroughly in our air bricks and air vents project.

Quite simply, if air bricks become blocked with debris or ground levels are raised this cuts off the air flow preventing moisture from evaporating. Additionally water leaks may also occur.

Timber damaging insects and most types of rot all thrive in these moist humid surroundings so it is absolutely essential that air is allowed to flow freely in and around timber floors.

So in many cases the floor timbers and joists become so badly damaged you may feel the only answer is to replace the damaged timber floor with a concrete floor. Again, this is not a small undertaking and requires a lot of work and planning but if this is the only course of action to take then it has to be done.