A door frame or door liner as they are also known is an integral part of a door, enabling it to be correctly hung in an opening and ensure that it opens and closes as it should.

In this DIY guide you will learn all about the humble door frame, read on below.

What is a Door Frame?

A door frame is the framework that a door is hung on and mounted and allows it to open and close correctly.

In pretty much all cases, all internal door frames are made of wood and are generally either 4 (100mm) or 5 (125mm) inches in width.

The width of timber that should be used to form a door frame will very much depend on the opening it’s being fitted into.

In most cases an internal door frame will be fitted in an opening in a stud wall (find out more about stud walls in our project here) which will either be made using 3×2 or 4×2 inch timbers.

If the studwork is made of 3×2 inch timber then you will need to use 4×1 inch timber for your door frame. This is because the door frame will be fitted central to the 3 inch stud and will leave a 12mm or half inch overhand either side. This overhang equates to the thickness of a 9mm sheet of plasterboard with a 3mm thick plaster skim over it which will leave the finished surface flush with the door liner or frame.

Likewise if your stud wall has been constructed using 4×2 inch timbers then you will need to use a 5×1 inch timber for your liner to achieve the same result as the above.

In terms of external doors, the door liner or frame will in most cases be constructed using the same material as the door itself. For example if you have a hardwood timber front door then the frame will most likely be made of timber, but if you have a UPVC or composite door then the frame will be made of the same material with an aluminium core.

A door frame or door liner can be purchased as a kit that you assemble yourself from pretty much all DIY stores and builders merchants, these are normally around the £32 mark.

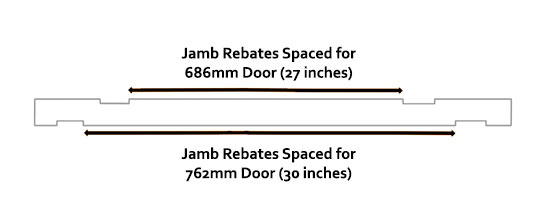

A pre-made door frame kit can be used for 2 different opening sizes due to the fact that on the door frame head piece there will be 2 sets of rebates cut, one set spaced for a 626mm (27 inch) door and the other for a 762mm (30 inch) door. Simply fix the jambs into your desired rebate and then cut off the excess timber from the head.

Door frame head piece showing 2 sets of rebates for 686mm and 762mm wide doors

The cost of buying a door liner or casing kit has steadily increased over time but a cheaper option is to make your own door liner or casing using suitable timbers, more on this can be seen below.

One very important point to note when fitting door frames and hanging doors is that you always fit the door frame and then cut the door to fit the frame, you NEVER cut or adjust the frame to fit the door, fit the door to the frame!

Parts of a Door Frame

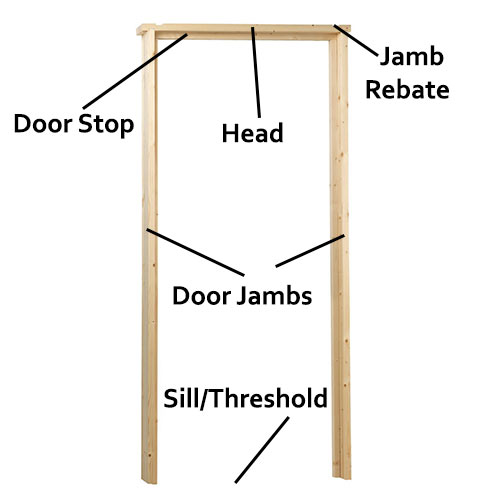

There are several parts that make up a door frame; the head, the jamb or jambs, door frame stops and the door sill or threshold. Many also class the architrave as part of the door frame but this isn’t necessarily the case as this is merely the finishing covering to disguise the gap between the door frame and the opening.

Head and side jambs of door frame

A description of each part of the door frame is as follows:

- Head: The head of a door frame is the horizontal section that sits at the very top of the frame and features 2 rebates for each of the jambs. The head fixes the jambs in place top form the frame itself

- Jamb(s): The door jambs sit at either side of the frame and form the frame itself. The jambs provide a vertical fixing point for the door allowing the hinges to be fixed one side and the lock or catch rebate on the other

- Door Stop: Although not technically part of the frame they are an integral part of the frame and prevents the door swinging inwards and outwards. They are fixed around the inside of the frame or jambs at 1mm or so over the thickness of the door to allow it to close and sit flush with the outside of the frame.

- Door Sill or Threshold: A threshold or sill is normally found on an external door and not on an internal door. The sill or threshold forms the very base of the door frame at the opposite end of the head section. Its main job externally is to help channel water away and prevent it running inside your property

The parts that make up a door frame or door liner

How to Assemble a Door Frame Kit

One of the major advantages with the door frame kit is that it can be quickly and easily assembled.

Firstly clear a space large enough for you to unpack and put the frame together.

Next, place the head section at the top of your assembly area and then put the two jambs at either side. Ensure that you have the head piece the correct way round for the size of door you will be fitting into the frame.

Hold the head vertically up on its side and take one of the jambs and slot it into the appropriate slot for the size of door. Screw down through the head, into the jambs using 75mm wood screws to hold the first jamb firmly in the head.

With the first jamb fixed in place repeat the above for the second jamb.

Measure the distance between the jambs at the head of the liner, and cut a piece of timber slightly larger than this length.

Fix this piece of timber over the top of the jambs at the bottom of the frame. Don’t fix it internally as once the frame is in place in the opening then you wont be able to undo the screws. Fix the timber so that it holds the jambs at the precise same width as the gap between the jambs at the very top.

Adding this will keep the frame sturdy while you fit it in the opening.

Timber fixed at base of jambs to keep it square

To make sure the frame is completely square, you should use a framing square or a carpenters square to get it in position, then nail a timber brace across the angle from the head to one of the jambs (as shown in centre picture above) to keep it in position. Again fix this across the front of the jambs.

Both jambs in position and squared using cross bracing

Once your door frame is perfectly square, use a handsaw to cut the excess overhangs off of either side of the head section so they are flush with the side of each jamb.

How to Make a Door Frame

As we have mentioned, to reduce the cost of fitting or replacing a door frame, instead of purchasing a door frame lining kit you can make one your self.

First, measure the width and height of the door you are going to fit in the frame once it’s installed. Add 1/4 of an inch (6.25mm) to the width and 1/2 an inch to the height. This is to allow some movement room once the door is fitted. Trying to be too accurate and making the frame the exact same size as the door is not a great idea in tis case as it can cause binding and poor fitting.

Select the correct size timber for your door frame. As mentioned above use 4×1 inch timber for 3×2 inch studwork and 5×1 inch for 4×2 inch studwork. If you are fixing into a masonry opening, measure the depth of the bricks or blocks used to form the wall and select timber of the same width to match.

If it’s a slightly odd size of opening then use timber that’s slightly bigger and trim it down to the correct size.

Next cut a head section for your door frame to the width of your door plus the additional 6mm (1/4 inch) that will give a 3mm gap all the way around the door, plus the thickness of each of your jambs that will sit at either side. As we are using 4×1 inch this will be an additional inch or 25mm either side, so for a 762mm door the head will need to be 818mm in width (762mm + 6.25mm + 50mm)

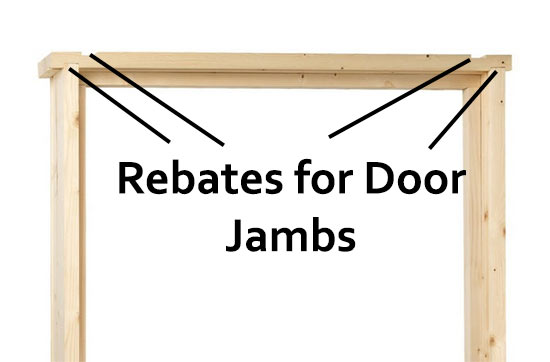

To ensure the jambs remain at exactly the correct with we are going to cut some rebates at either side at half the depth of the head, in this case 12.5mm as the head is 25mm or 1 inch thick.

At either side of the head measure and mark 25mm in on the underside and then 12.5mm up at either side. Using a handsaw cut this section away ensuring your cuts are accurate.

Rebates cut at either side of head section to fit door frame jambs

Repeat the same for the side jambs, taking the height of the door plus an additional 12mm movement room and depth for carpet etc. and an additional 12mm for the rebate in the head. Cut your side jambs to length.

On the top of the head section, drill and countersink pilot holes at either side rough 12mm in or at the centre of each rebate.

Position the first door frame jamb in position and using 75mm wood screws, screw down through the head section into the jamb fixing it firmly in place. Repeat the same for the other jamb also.

Once the jambs are fixed to the head cut a timber slightly wider than the head and fix it at the base of the frame ensuring the gap between the jambs at the top is exactly the same as at the base (same as above). In the same manner as the above, also fix a diagonal cross brace from the head to one jamb to keep the door frame fully square.

Door frame made from scratch

How to Fit a Door Frame or Door Liner

Whether you have purchased a kit or made your very own door frame from scratch, once it’s fully assembled it’s ready to be fitted into your chosen opening.

Fixing a Door Frame to a Studwork Opening

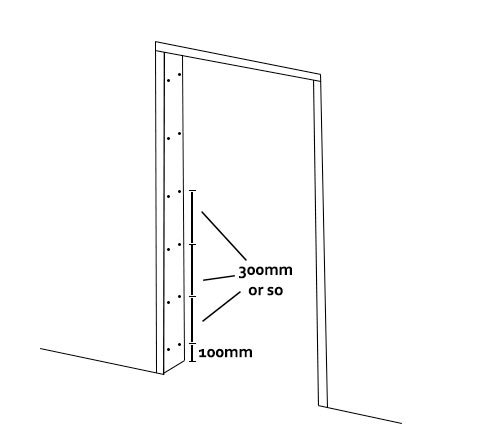

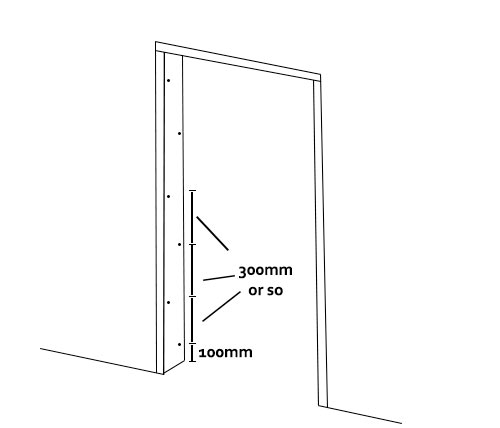

How it’s fixed will depend upon what material you are fixing into. In most cases this will be a timber stud frame and in this instance you will need to screw your door frame at both sides of the frame roughly 25mm in from each edge starting 100mm up from the base every 300mm or so up the frame.

Fixing points for door frame when fixing to a timber stud frame

It is essential that the door frame is fixed like this so that it is fully secured and will in no way move. If it’s allowed to move then this can cause the door to open and close incorrectly, bind on the hinges and also bind on the frame.

As the frame itself has been formed to the size of the door there is the chance that once the frame is inserted into the opening that it will be slightly smaller and due to this there will be gaps around the sides.

In this instance, before screwing the frame up you will need to pack it out. If you don’t then when you screw it up to the studwork it can warp the frame and if the frames warped then the door wont open and close correctly.

To pack out any gaps the best items to use are standard packers. These are pieces of plastic formed to set depths that can be inserted into the gap between the frame and opening and ensure when the frame is screwed up the packer holds it firmly and ensures it doesn’t cause the frame to warp.

Packers used to ensure no movement when door frame is screwed up

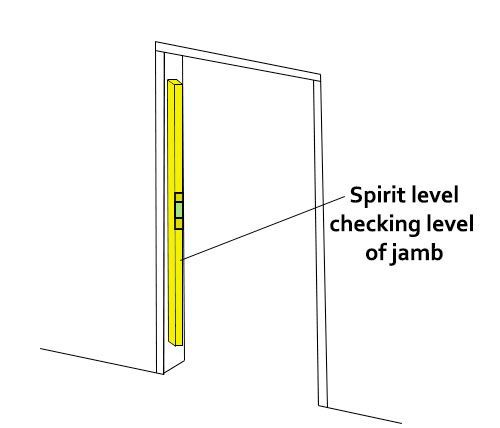

To ensure that the frame remains totally square as it’s screwed up you will need to keep a long spirit level placed on the inner face of each jamb and a shorter level across the head.

Before inserting the frame into the opening mark out each fixing point and drill a pilot hole and countersink each hole. Once done push the frame into the opening and pack out any gaps.

Screw each screw into each fixing hole until it starts to bite and with your level in place sequentially tighten each screw a little, working your way around all of them steadily until they are all tight. Keep a close eye on the spirit level and ensure it remains totally flat to the inner surface of the jamb.

If a gap starts to appear under the level then loosen off the last few screws until it’s level again.

Spirit level placed on inside of door jamb to ensure it stays level as its fixed

The same is also the case when securing the head in place. Use a short spirit level to monitor it and ensure it’s not warping when any of the screws are screwed up. Where any gaps are present use packers to fill these out.

Fixing a Door Frame into a Brick or Block Opening

When fixing a door frame into a masonry (brick or block) opening, its a similar process to fixing it into a timber stud frame. The main objective is to ensure that the frame remains totally square and does not distort as it’s fixed.

The main difference between the two comes in the way that the frame is screwed to the masonry. As opposed to being fixed at 2 points either side of each jamb along its length, all screw fixings are staggered.

The purpose of staggering them ensures that the bricks or blocks don’t split as fixing holes are drilled and screws inserted.

Each fixing hole should be drilled around 1 1/2 inches or a 1/3rd or the width from each edge and around 250-300mm or so apart.

Staggered fixing holes on door frame jamb when fixing to brick and block openings

As with fixing to timber studwork, mark out all the fixing holes on the inside of the jambs and the head and drill pilot holes and countersink them.

To fix the frame in place insert it into the opening and fully level it up and use a small masonry drill bit to drill through each hole and mark its position. Once marked remove the frame and put it to one side and then use a drill and 6mm masonry drill bit to drill out each fixing hole.

Once each hole is drilled insert a red wall plug and push the frame back into place in the opening and screw ` screw into each fixing. For full information on how to fix to masonry surfaces see our project here.

As before keep a spirit level on the inside of each jamb and keep an eye on it as each screw is screwed up to make sure it doesn’t twist or warp. If it does, loosen screws until it comes back into shape. Repeat this for the head section also.

Once all screwed up the final job is to fix some door stop in place. Measure the thickness of your door and mark this plus 1mm around the inside of each door jamb and the head. Measure and cut some 12mm door stop to length and nail it to each jamb and then measure the gap across the head between the 2 sections of door stop that are already fixed and cut a section to size and nail it in place.

Once the door stop is in place that’s pretty much it you have now successfully fitted a door frame. The final job that’s left is to now hang your door in the door frame. For full tips and help on this see our hanging a door project here.