Most of us these days take it for granted that, once the front door of your house, flat, barn conversion or wherever you call home is closed, then you are totally sealed and weather proof.

Depending on the type of front door you have, this may not necessarily be the case as if you do not have a weatherboard fitted to your door then you may be allowing water and moisture to creep in under the door itself.

If you have a modern uPVC or composite door then generally you are pretty safe. Most of these types of door will feature an integral seal built into the door itself that will prevent any form of moisture from entering the property, but, overtime, these seals will themselves compress and deteriorate increasing the chances of damp getting in.

If you, as we do, live in the UK you will be well used to the “slightly damp” climate that we live in and due to this will most probaly be well versed in spotting and fixing the various routes that water can take to find it’s way into your home.

To these ends, in this project we are going to take a look at how to fit a weatherboard (rain deflector, drip bead, weather bar as they can sometimes also be called) and how these marvelous contraptions prevent water ingress through the bases of exterior doors.

What is a Weatherboard?

Essentially a door weatherboard is an angled or beveled piece of timber, metal or rigid plastic that is fixed to the bottom of an exterior door that fits between the door jambs (or stiles as they are also known).

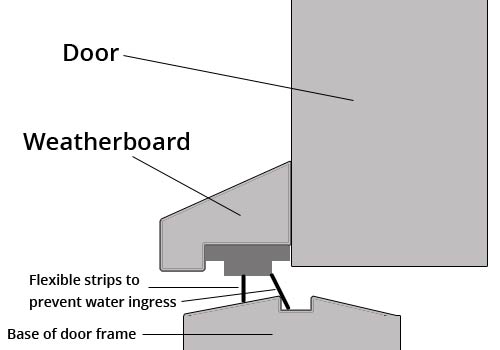

Weatherboard fixed to door

They are most commonly found on timber doors and their primary purpose is to stop water from running down the face of the door itself and reaching the often unprotected underside where it can then soak in to the timber and over time rot it out.

It’s other purpose aside form protecting the doors underside, is to stop water from entering into a property through any gaps between the door itself and whatever may be beneath it. This could be a floor, base of a door frame, doorsill or threshold etc….

As you may notice in the image below, in the base of the weather strip or drip bead there is a slight recess. The main function of this is to prevent any water or drips tracking backwards.

Once it reaches the recess, it then simply drops down to the floor well clear of the door itself.

Some manufacturers will also fit a rubber strip to this recess that, once the door is closed, creates a seal between the base of the door and the floor, frame or threshold, that provides a further barrier.

Recess in base of weatherboard

As we have mentioned already, if you have a uPVC door or indeed a composite door then in some cases it may not be necessary to have a weatherboard fitted (although most doors of this type come with one already fitted).

This is due to the fact that most doors of this type are fitted within a frame that contains the entire door within it.

Sealed into the edge of the frame is a spongy rubber seal that, when the door is closed, seals any gap between the door and the frame and creates an impenetrable barrier preventing any possibility of water getting in.

Rubber seal in the frame of a uPVC door

Despite this, most uPVC plastic and composite doors are supplied with a weatherboard for good practice as they also stop any buildup of water along the seal at the base that can collect and when the door is opened, then spills in.

For some odd reason, hardwood and timber exterior doors very rarely come fitted with a weather strip or board, even though the weatherboard itself is mainly geared towards preventing water ingress and damage on exactly these types of doors.

Possibly this is due to the fact that you may need to cut the door to fit, but that’s a question for another day.

With the above in mind, if you have a timber door, you will need to purchase your own.

If you have ever seen a stable door (door that’s split in the middle and both top and bottom can be opened or closed) then you may also have noticed that there is often a weatherboard fitted to the base of the top section of door as well as the base of the bottom one.

For the same reason that there is one at the base, this does exactly the same job – stops water from entering through the gap between the two section of door.

Stable door without weatherboard

Stable door without weatherboard

When sourcing a weatherboard for your door, make sure that the one you go for is exactly that; purpose made for precisely this job and shaped in such a way as to direct any water running down the face of the door away.

A hardwood weatherboard will last a lot longer than softwood, but if your door is made of pine there’s not much point in fitting a hardwood one that will likely outlast the door itself!

As to where to get one, any decent DIY store or builders merchant should stock a selection of different styles and material types.

Types and Styles of Weatherboard

In terms of style, all weatherboards are of a similar design, essentially as the lip itself ensures that the water is directed away from the face of the door.

Despite the standard design, they do however come in a range of different materials:

Timber – Hardwood or Softwood

If you have a timber (either hardwood or softwood) front door then in most cases you will want to go for a timber weatherboard to match.

If you employ a company to fit a new door for you then in most cases they will offer the option to have one fitted during installation or you can indeed fit one yourself (see below for instruction).

As mentioned, most builders merchants and DIY stores will stock a range so they should be readily available.

As you can see in the image below, this particular example has a drip recess on both flat edges and you will find that most examples do. This just means that it is reversible and can be fitted either way around.

Reversible timber weatherboard – Image courtesy of doorweb.co.uk

One final point to make concerns the type of timber used in construction. If possible, always go for a strip made of hardwood as opposed to softwood as it will last much longer.

Plastic uPVC or Composite

As with the above, upvc weather strips are all of a similar design and shape, the only real differences come in their finish and construction material and the way in which they are attached to the door.

In respect to their construction firstly, in almost all cases they will either be made of straight uPVC plastic or a mixture of uPVC and coated with GRP.

When it comes to fixing to a door there are a few different methods. If you are fixing one to an existing door then most probably it will come as two pieces; the weatherboard itself and a mounting bracket.

The mounting bracket will simply be screwed to the door and then the weatherboard simply slots on to the bracket and is usually secured via a screw or clip.

If you are having a new door fitted with a supplied weather strip then in most cases the bracket part will be moulded/included as part of the door and the strip itself will again just slot over.

UPVC door weatherboard

Aluminium or Steel

As with the uPVC variant above, this type will also mostly come as a two-part piece, with the bracket being fixed to the door and then the strip slotting over it or they can also come as a one-piece unit that is then screwed to the door.

When it comes to styles, the slot-and-bracket type will look like the standard lip-type as seen in the timber and uPVC variants above but the all-in-one type can look slightly different in that it appears to have two lips.

This is mainly down to the fixing, as access is needed along the entire length to ensure it can be secured in firmly. The top lip then directs water outwards over the second lip that protects the base.

Aluminium weatherboard – Image courtesy of stormguard.co.uk

How to Fit a Weatherboard to a Door

For the sake of this project we are going to run through the process of fitting a timber weatherboard. However, the principles of fitting other types is pretty much the same.

1. Measure and Cut to Fit

As pretty much all front external doors open inwards (to prevent you opening a door a door in someone’s face), close the door making sure it is fully shut.

Now, measure the distance between the door frame uprights or stiles and make a note of this number. This is the width that you are going to need to cut your weatherboard to.

Make sure your measurement is accurate and will form a nice snug fit as if there are any gaps, water is sure to find its way in.

In pretty much all cases, you are going to need to cut your weatherboard to size as it will come in lengths of around 1 metre.

Before cutting to correct length, on one end, cut a slight mitre of around 15-20° from the back to the front e.g. the front being narrower than the back (the mitre angle ensures the weatherboard won’t hit the door frame as the door is opened and closed).

Now, measure and mark your cutting point along the back edge (not the front edge with the mitre) and then make your cut at the point you marked.

Pay attention to where you made the mark e.g. is it directly on the cutting point, or to the left or right? Make sure you’re cutting in the right place!

Cut the weatherboard to length and again, cut a mitre of the same angle as the opposing end.

Measure the width of the door frame

2. Test Fit and Mark Fixings

Before you actually fix your weatherboard to the door, you need to do a test fit to make sure all is well and the fitment is correct.

With the board positioned as far down as possible, but not touching the sill and leveled (use a spirit level for this), draw a line on the door along the top edge of the board. Again, make sure this line is level as this marks your final fixing point.

To ensure it stays level whilst making your mark, it’s a good idea to get a second pair of hands to help you.

Finally, mark the fixing positions on the front of the board. Three fixings should be enough to hold it firmly.

Mark fixings at either end around 30mm in from each end and then one in the middle. Use a tape measure to mark these points accurately.

Once marked, remove the weather strip and place on a firm surface or work bench. Drill out your fixing points and then countersink the holes (tips on how to drill pilot holes and countersink can be found here) as we are going to fill over the fixings at the end.

Mark a line on the door where weatherboard will be fitted

3. Stain or Prime and Undercoat

Before fitting it’s a good idea to fully stain or prime and undercoat the entire strip as this will provide full weather protection and ensure it lasts for a good long while.

Before adding your chosen protective coating, give it a light rub over first using 240+ grit sandpaper to take off any rough edges and also to provide a decent key to your final finishing’s.

If staining, apply your first coat over the entire object, making sure you fully cover any nooks or crannies and then allow to dry for manufacturers recommended time before applying any second or third coats.

If priming/undercoating, apply your primer making sure you are using the correct type and then allow to dry before applying your primer. Check with the manufacturers instructions as to whether you need to apply one or two coats.

Once primer and undercoats are dry, apply your finishing coat. Normally this will be a colour match to the finish of your existing door, but this is really down to you.

Exterior woodstain

4. Fix it in Place

Position the weatherboard back against the door, lining it up against the line you drew earlier. Screw the board into place, making sure it stays level.

Once fixed, try opening and closing the door to make sure that the weatherboard doesn’t catch against the doorframe or anywhere else.

In the hopefully unlikely event that it does, use a plane or sandpaper on the part that catches until it doesn’t touch any more.

Screw the weatherboard to the door – Image courtesy of diynetwork.com

5. Seal up any Gaps and Finish up

With everything now fixed securely in place and the door opening and closing as it should it’s time to apply your final finish.

Using a suitable exterior wood filler, fill over your countersunk screws making sure you push the filler in fully. If you can find one that’s a close match colour to the final colour you’re going, that’s best as if you are staining then the stain will not soak in fully and they will always show slightly.

Leave the filler to dry fully as recommended by the manufacturer and then rub each point down until it’s flush and smooth.

Apply a finishing coat over the fixings and any other areas that have been rubbed down and as before, once this has dried apply a second and third coat if needed.

Once the final finishes have dried, the final job is to run a seal of silicone or other sealant along the top edge where the board meets the door. This is to prevent any chance of any water seeping in.

If you need any advice on using sealant and a sealant applicator gun, see our project here.

Brummer exterior wood filler

As you can see from the steps above, the principals can easily be applied to the other types of weatherboard.