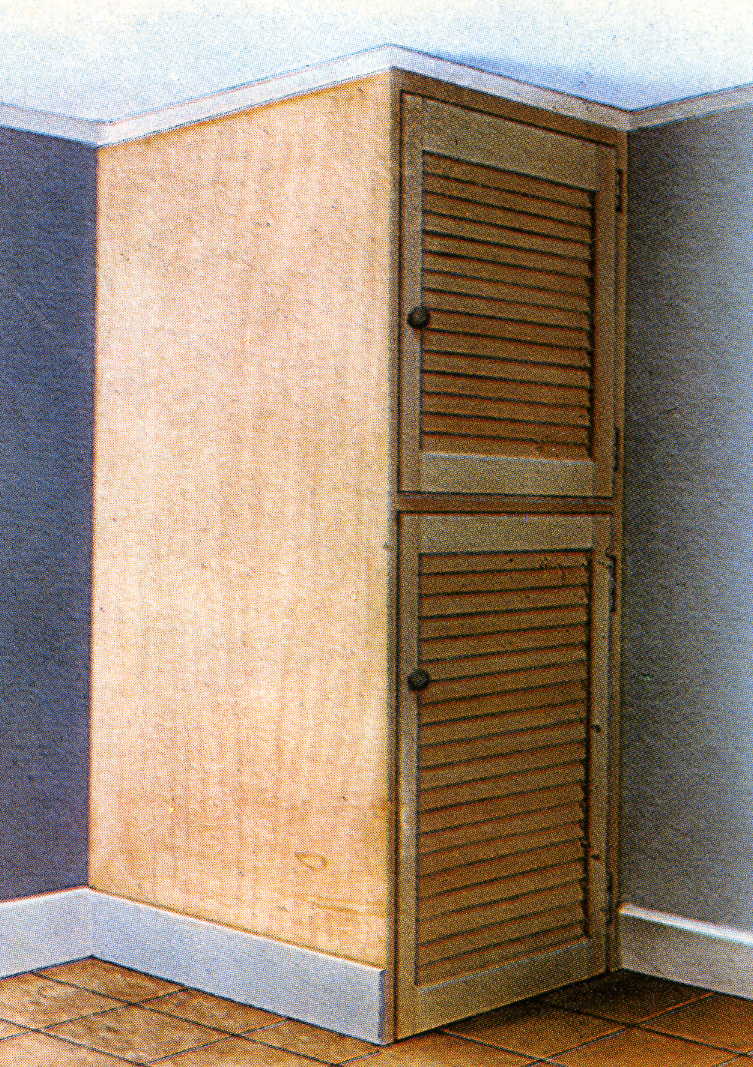

This project contains basic principles for building a frame for a basic cupboard. It can be expanded on by using different designs, the struts can be moved to accommodate shelves or simply left open plan.

It will give you the idea of building storage space onto your home and can even be adapted to make a corner cupboard. The timber sizes can be changed and more struts can be put in to ensure greater strength if you feel you need it.

The structure can be fixed to any wall, ceiling or floor using our guides to fixing. Check the wall, floor and ceiling area for pipes and cables before you drill anything.

Tools you will need. Most of these can be found at the bottom of this page, the rest can be found by clicking on the toolstore link at the bottom of the page.

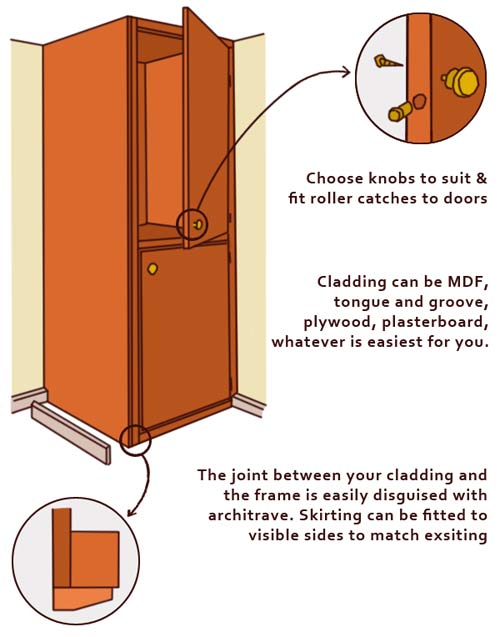

Completed Timber Cupboard

We suggest for this simple cupboard you use 50 x 50mm PSE timber. This stands for Planed, Squared Edge and simply means prepared for joinery, as opposed to the "sawn" state timber is in when it leaves the timber mill. It is also called, in its prepared state, PAR which is Planed All Round.

With the number of different door designs available from kitchen and DIY stores these days we suggest it may be a good idea for you to find the doors (if you intend to have them) first. The frame can easily be built around the door size and you will have guaranteed matching your existing decor.

We have deliberately not given any dimensions in the project. Even when planed timber can vary by a mm or so and ceiling heights can vary considerably. Measure your own timber and other dimensions carefully and remember. Measure twice-Cut once

Use a carpenters square to make all cuts. Neat joints are impossible without a completely square face to begin with. Also if the timber is not square at the end, a measurement to the other end will vary, depending on which side you measure from. This can make it impossible to get a decent finish.

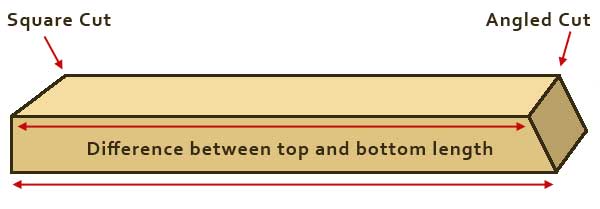

Square Cuts and Angled Cuts

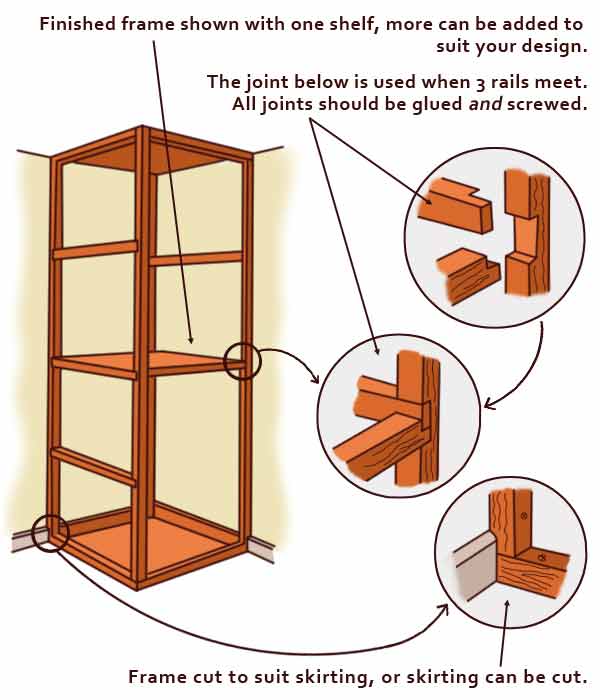

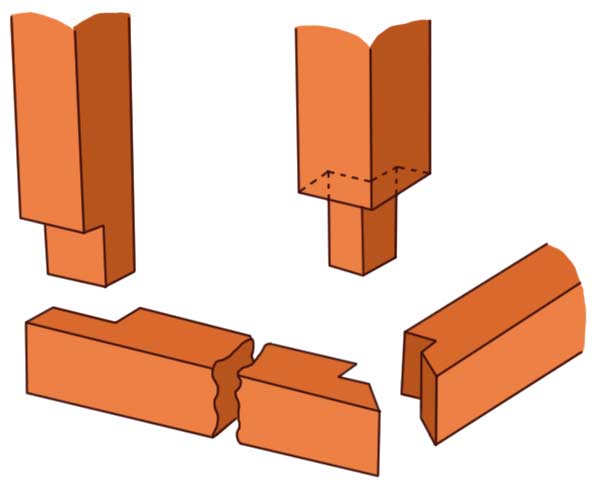

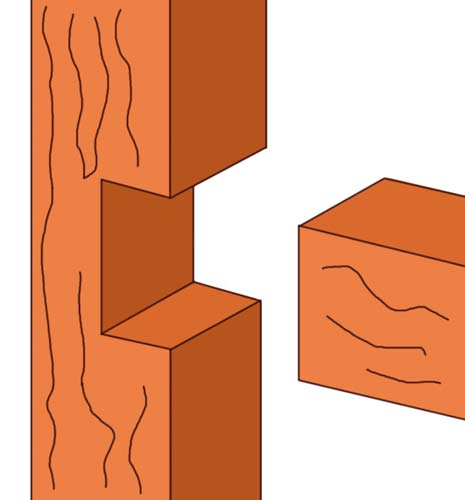

A variety of joints can be seen in our timber joints projects and some special joints are shown here. The principle of cutting them is exactly the same as shown in the timber joints projects.

Please remember it takes many years to become a carpenter or joiner. If this is your first project, or you have not done much carpentry, buy an additional length of timber and practice your joints before embarking on a project which will become a feature in your home. An 8 foot length of sawn timber to practice on will cost pennies compared to the waste of materials if you mess up with the real thing.

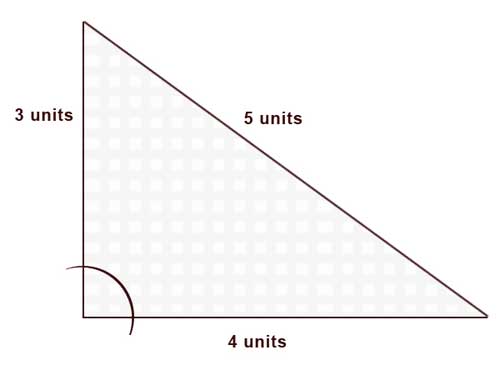

Check your walls are square to each other using our 3, 4, 5 method shown below.

HOW DO I CHECK MY ROOM IS SQUARE (click on link for more tips and tricks)

Floor tiling, carpets, any number of things around the home require a degree of setting out. Remember a quarter of an inch out at one end of a 12 foot room, means about 2 inches out at the other end.

It is important to start any appropriate projects with straight and square lines and it is very easy to accomplish. The method is called 3,4,5 and for the technically minded is based on Pythagoras’s theorem which we won’t go into now! Suffice to say that if you measure along one wall 3 feet (or metres or any other unit), and along the other wall 4 of the same unit, the diagonal line in between the points should measure 5 units. If it does your walls are square, if it doesn’t, you need to mark some points that are square to start your work.

Angle Diagram

Draw your plan before you start.

Timber Cupboard Plan

All joints need to be "made" before any of the frame is fixed to the wall, floor or ceiling. Once cut, fix the two uprights absolutely vertically on the walls using the struts as spacers to get them in the right position.

Fix the struts and the centre upright together using glue and screws. Make sure the screw heads are counter sunk into the timber or they will push the cladding out. Use a tenon saw to cut the skirting back if you prefer that to cutting the frame around the skirting.

The frame can be fixed to the wall using a 7mm masonry bit with red wall plugs and (for 50mm timber) 3 inch, number 8 screws. For fixings to plasterboard use our guide. Also fixing to lathe and plaster.

Floor/ceiling and cross rail joints

Cross rail to post joints

Mark the position of the struts lightly on the walls when your frame is in place. You will not be able to see them when you are attaching the cladding, making fixing to them a bit of a lottery. The pencil marks can be rubbed out later.

Next, cut and fix the shelf or shelves. This can be done more easily when you can get to all sides. The side rails which support the cladding should be fixed at no less than 600mm centres for 12.5mm cladding and if your cladding is thinner than that, they should be spaced at 450mm centres.

The shelves and cladding material we have left up to you.

Shelf and Cladding Ideas

We always prefer to use screws to fix the cladding to the frame even if we are using plasterboard. Sink screw heads into the cladding and fill over them to get a flush face on which to decorate.

The joints between the cupboard and the wall/ceiling can easily be filled with flexible filler or decorators caulk using an sealant or "applicator" gun as shown below. Alternatively you may like to fix some coving or a shaped timber moulding.