Over time, rust, debris and sludge can develop in your heating system and as it flows around it can easily build in certain places, causing blockages and restrictions which can seriously affect how your heating system works.

Although there are many additives that can be added that help to reduce such issues, when blockages occur one of the only solutions is to flush central heating systems out, refill the system with fresh water and start again. This is know as power flushing. Read on to find out all you need to know.

What is Power Flushing?

A power flush is the process of cleaning out a central heating system by circulating high volumes of (forced) water and cleaning agents around a heating system to remove debris, rust, sludge and other rubbish that develops over time.

When such junk builds up it can seriously affect the flow of water around your heating system causing it to become much less efficient and take much longer to heat up and ultimately cost a lot more run.

Additionally, with all of that rubbish floating around it your system it’s only a matter of time before it finds it’s way to your boiler or heat source, again causing blockages and ultimately failure which is generally accompanied by hefty repair bills!

Quite often, certain chemicals are added to the water in your system to help reduce such build up, but these only go so far. Essentially the older your system is, the more chance of sludge buildup.

To keep your heating system in tip top health, this is where power flushing comes in. High pressure water and a mixture of chemicals are forced around your entire heating system, loosening and dissolving all of the rubbish and the waste is then disposed of.

The system is then refilled with fresh water and inhibitors to keep future deposits at bay and once turned back on, you should then have a perfectly functioning heating system.

Power flushers come in sizes which range from a 20 litre tank which is enough for a 25 radiators to a 200 litre tank which will keep going for the largest of commercial properties. The power flushing pumps can be hired from your local tool hire shop. Many pumps have an instantaneous flow reverser to make life easier.

When do you Need to Flush Central Heating?

There are several telltale signs to look for with your heating system to know whether it needs a power flush or not.

Generally if you have cold spots on your radiators, or your radiators are cold at the bottom and warm at the top, this is a potential sign, especially if you have bled them and this has made no difference. Sometimes one radiator in your system may not be working at all and this is a sure sign that a flush may help.

If you heating system has feed and expansion tanks in your loft and these have a lot of sludge in them, or the heating system is very slow to warm up these are both indicators that a full system clean is required. Another indicator of the need for a power flush is if your thermostatic radiator valves are stuck in the off position.

To summarise, your heating system needs a flush if any of the following are true:

- Your heating system take ages to warm up

- Some radiators cold at the top or bottom

- Some radiators do not get warm at all

- You have to bleed radiators regularly

- Deposits in feed and expansion tanks in loft

- Leaking radiators

- The boiler makes excess noise when running

- Supply pipes hot but radiator lukewarm or cold

- Dirty coloured water when bleeding radiators

Once your system has been fully power flushed, you should then benefit from the following:

- A heating system that heats up fast

- All radiators fully heated up with no cold spots

- A much more efficient system

- Cheaper bills

- A warmer house

- Reduced risk of breakdowns

What Regulations Cover Power Flushing?

Although there are no strict rules currently in force that govern when you should get your heating system power flushed in terms of routine maintenance, there are some that you need to be aware of when it comes to commissioning and replacement.

When a heating system is first commissioned in a new build property e.g. newly installed, then according to Part L of the building regulations and British standard BS 7593:2019, the whole system first needs to be power flushed before any inhibitors are added and the system is then finalised for use.

Similarly, and also in accordance to Part L and British standard BS 7593:2019, if a boiler is replaced in an existing heating system, before it’s refilled and turned on, the full system must also be power flushed.

Is Power Flushing the Same as Chemical Flushing?

No, power flushing a heating system is not the same and chemical flushing. In the latter, chemicals are used to break down deposits where as with a power flush chemicals are used along side a high pressure pump to blast debris out.

With a chemical flush, a range of chemicals are added to the water in your heating system that flow around and gently break down rust and deposits. This is left in the system to circulate for a while after which it is then flushed and refilled.

With a power flush, chemicals mixed with water are forced around your heating system at great pressure, blasting deposits free. Once several cycles are completed the system is then refilled for use, almost always within the same day.

When Should you Flush Central Heating Systems?

There are no hard and fast rules about when you should power flush your heating system, but a good rule of thumb is somewhere around every 5 years as this will keep it in tip top condition.

Ultimately, it very much depends on how often you use your heating and also when it was first commissioned, were the appropriate rust and corrosion inhibitors added to prevent rust and sludge build up. Or, if the system has been drained down, were they added back when refilled.

If not then this will have a dramatic effect on how much rubbish will build up over a short space of time and when the system will need to be flushed.

Is DIY Power Flushing Possible?

In terms of regulations, there is nothing anywhere to say that you cannot do a DIY power flush, however without the expertise that a qualified GasSafe heating engineer will have, if you get into any problems then it’s likely you wont know how to resolve them and will end up having to call the professionals out any way.

One other thing to bear in mind is that you are flushing out and removing heating sludge and if you’ve ever seen what this looks like you’ll know how much of a messy job this could be and without knowing what’s going to come out where there’s a chance that you may get it all over your carpets or other surfaces causing a huge amount of expense to resolve.

Flushing Central Heating Systems – How to Power Flush

If your heating system is suffering and you have identified that it needs to be power flushed then work through the following steps for flushing central heating systems. You will need to hire a power flush machine from your local hire store.

Step 1 – Identify Problem Radiators

The first job to do before cleaning anything is to record the temperatures of any and all problem radiators so that once you have cleaned the system and it’s back up and running again you can take an after temperature to compare to your first one and ensure that the flush has actually resolved the issue.

Using a standard thermometer, place it on the cold area and record the temperature. Take note of where you place it as you will need to place it in the same spot for the retest later.

Repeat this for any other problem radiators.

Step 2 – Record all Settings

The next job is to go around your whole heating system and make a record of any and all settings so that when you have cleaned the system and it’s recommissioned, you can then put everything back to how it was.

First, record the setting of each TRV (if you have them) on each radiator and once recorded, unscrew it and place it next to the radiator it came from. This is so that the valve fully opens and you get maximum flow.

Also, make a note of how you have your controller is configured, you shouldn’t loose any settings but just in case, and also any other valves in the system e.g. any wheel head valves for feed and expansion tanks and the likes.

Finally, make sure you also take note of the position of each lockshield valve (not the TRV, the one at the other end). This is usually a case of using a felt tip to mark it’s current position on the cap and the valve, so that you can then line them up afterwards.

Step 3 – Prepare System for Power Flushing

Once you have recorded the settings and temperatures, the next task is to identify the type of system you are working on e.g. sealed (combi-boiler) or vented (header tanks in loft) and then get the system ready for its power flush.

Before we progress any further, it’s worth stating now that if you are power flushing due to fitting a new boiler, to prevent any damage to the boiler, the power flush should be done prior to fitting it, or if it’s already installed you can simply bypass it.

Firstly, turn off all the power to the boiler or heat source and any controllers/programmers you have. If you’re working with a combi system then it should all be run off the boiler so when you turn the plug off it should all go off.

If you’re working on an open vented system you will need to turn off the mains valve. If for any reason like your stop cock is jammed or broken as this sometimes happens, you can go to your header tank and tie up the floating ball valve to stop the system refilling.

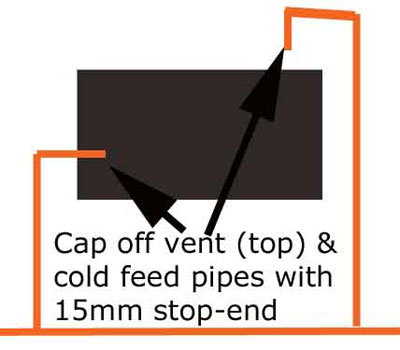

Also, for open vented systems you will need to cap off the open vent pipe and the cold feed pipe running to and from the feed and expansion tank. If you can’t cap them off you can join them together.

Capping off the vent pipe and down feed pipe to the feed and expansion tank for power flushing the central heating system

If your system features any non-return or anti-gravity valves you will need to remove or bypass these as this will prevent the reverse flow feature of the flush from working.

Once the above has been taken care of, you can now go through the check list below to make sure you are ready to power flush.

- Switch off boiler (just check to make sure it’s off)

- Open all your radiator valves fully

- If you have one, the diverter valve should also be fully open. This is also the case for any zone valves

- Close off your water supply

- If you have a sealed system you will need to de-pressurize the system and drain off some of the water contents to bring the pressure to atmospheric pressure

Step 4 – Connect up Power Flush Machine

With all the prep work now taken care of the next job is to get the power flush machine connected up. How this is done will depend on what type of system you have and the type of machine you’re using.

Full instructions on how to do this should be supplied with the machine and if not, contact the company you’ve hired it from and they will be able to tell you exactly how it should be done.

Generally, if your system features a pump then you can connect via the flow and return pipes to the pump.

To do this, close both isolating valves that you should have either side of your central heating pump. You are then in a position to be able to remove the pump from your system. You can now connect your power flush system to the heating system using the connecting manifold. This is generally for the more expensive machines.

However, with the cheaper options you will be limited to connecting your power flush to your central heating system via your radiator valve tails.

To connect via this method, turn off your radiator valves, disconnect one, and also the air bleed valve (the one used to bleed radiators) so that it’s open and air can come into your radiator as this will allow all of the water to flow out from the disconnected valve.

When all the water has been removed from the radiator you can now connect your power flush to the return valves on the tails of the radiator.

Once the machine is connected up, make sure your dumping (waste hose) and overflow hoses go outside to a suitable drain or waste area.

Make sure that you have laid dust sheets or old towels all around the machine and the pipes used to connect to your heating system, just in case of any leaks or spillages.

Finally, Refer to the instructions on how to fill your machine with water and fill it up to the max level with warm water.

Step 5 – First Flush

With the unit full and ready, switch it on and allow it to start pumping the water around your heating system. Run it for 3 or 4 minutes or as instructed by the manufacturer to start loosening any rubbish.

After it’s run for a few minutes, stop it and add all of the necessary chemicals and turn it back on again and this time run it for around 15 minutes.

To improve its cleaning ability, every 5 or so minutes stop it and reverse the flow. This will hit any stubborn blockages from the other direction.

Once you have flushed the whole system for a period it’s now time to get a bit more granular and start focusing on some of the more problem radiators.

To do so, keep the open hot water circuit open and turn off all radiators except for the first problem one. Allow the unit to pump for a further 15 minutes or so, again reversing the flow every 5 minutes or so.

Once run for 15 minutes, repeat this process for every radiator on in the system one at a time.

Step 6 – Second Flush

With the whole system flushed and then each individual radiator also individually flushed we now move on to the second flush.

For this, once again close off all radiator valves except those to just one and remove the water, dumping it out the drain pipe to a suitable drainage point. To ensure it’s empty, periodically reverse the flow until the water runs clear.

Repeat this process for all other radiators in the system and once done, go around and open up all the other radiator valves and then run the flush once more, draining the waste off as you go. Keep going until all of the water runs clear at which point this means that all of the rubbish has been removed.

Note: Depending on what chemicals are being used, you may need to dispose of or neutralise them before disposal. Full instructions should be provided by the hire company on how to do this!

Step 7 – Recommissioning System

Before disconnecting the power flush unit, shut off the drain and then add the required amount of good quality inhibitor and allow the unit to circulate it for a good 10, if not 15 minutes to ensure it reaches every part of the system.

make sure that you add the correct amount as if not your system won’t be fully protected. Add more if needed and once this is done you’ve successfully completed the power flush!

Disconnect the power flush unit and connect your pump or radiator back up, ensuring that it’s isolated before you disconnect it.

Once everything is connected back, go around to each radiator, reconnect the TRV (if there is one) and set it to the correct setting. Also, set all lockshield, wheel head and other valves back to their exact position. Remove any caps you may have on the pipes running to and from the expansion tank if there is one.

Once everything is set back to what it should be, turn the power to the boiler and any controllers back on and fire the system up and allow it to get to temperature. Check any controllers or programmers are set back to what they should be.

Once up to temperature, go around each radiator and bleed any air off, check for any leaks and also temperature check the problem radiators to ensure they are now heating up as they should be.

If all is well and good, you should now have a totally healthy heating system!

Power flushing a heating system may sound like a very daunting job and if you are in the slightest bit apprehensive about doing it, definitely get the professionals in, however if you take your time and follow any and all instructions with your machine to a tee then there is no reason why you can’t complete such a job yourself.