An extractor fan is an essential part of any bathroom as it helps to remove the excess moist and humid air produced by the shower and keep any condensation build up to a minimum.

In this guide we take a look at how a timed fan unit or extractor fan with a built in timer is wired up, read on to find out exactly how.

Safety Regulations for Electricity

When it comes to electrical work in the bathroom, as this is regareded as a “special location” by the regulations, any electrical work can and should only be carried out by a Part P registered electrician so that it is ensured the circuit is installed correctly and to regulations standard, can be fully tested once complete and finally a minor works certificate can then be issued to sign everything off.

If it isn’t and there is no official evidence to prove it’s been done by a professional with the required qualifications then in the event of any issues it is likely that your home insurance won’t be valid and if you come to sell your home then this can again cause huge issues.

However, if you are simply replacing an existing extractor fan because it’s broken down or failed then you are allowed to do this under Part P.

Another point to be aware of is that in many installations a 3-pole isolation switch is fitted to the fan to allow it to be totally isolated from its electrical supply in the event it needs maintenance work.

Although not necessarily required by the regulations, it’s still a great idea to do. Also, ensure that you do actually use a 3-pole isolation switch as they are much more complete than a standard switch as they isolate all 3 wires that need isolating; permanent live, switched live and the neutral.

When it comes to the cable that should be used, as extractor fans are low voltage it’s possible to use 1mm or 1.5mm cable. Also, for timed unit extractor fans, as there is an extra cable you can use 3 core and earth, however if wiring a standard fan with no timed switch, 2 core and earth is fine.

If you would like to know more about staying safe when working on and around electricity then check out our electrical safety project here.

Types of Bathroom Extractor Fan Power Supply

When it comes to the type of extractor fan found in a bathroom there are essentially 2 different types; time switched and non-time switched. The main difference between the 2 is that with a timed switch, when the unit is turned off it will run on for a set amount of time to finish clearing the bathroom and when the time expires it then turns itself off.

With a non-timed unit, as soon as the power is turned off then the unit shuts down.

For both different types of units they can also be tuned on and off through normally 2 different means; they are either wired into the light, so that when it’s turned on the extractor comes on also or they have their own dedicated switch, normally as an isolator outside the bathroom above the door or inside as a pull cord switch.

This briefly covers the 2 main different types of extractor but for a full and detailed run down, see our types of extractor fan project here.

Types of Bathroom Fan Switch Configuration

As we have briefly touched on, there are 2 main methods for turning a bathroom extractor fan on and off. You can either wire it into the bathroom lights so that when they are turned on the fan comes on at the same time or you can wire it to its own switch.

When wired to its own switch, the switch itself will either be located outside of the bathroom, normally above the door or it can be inside as long as it’s in the correct zone and is a pull cord switch.

As it’s in a bathroom, although it’s not required, the belt and braces approach is to fit a 3-pole isolation switch so that all potential live points; permanent live, switched live and neutral are isolated when the switch is turned off.

In terms of zones and where a switch can be fitted, this is generally best done in an area of zone 3, but you have to ensure that the correct rating of switch is also used, but your electrician will know for sure what to use.

Tools and Products Needed to Wire a Timed Extractor Fan

In order to successfully wire up a timed bathroom extractor fan the following tools and products will need to be used:

- Small flat blade screwdriver

- Philips screwdriver

- Drill/driver

- Desired timed extraction fan

- 3-pole pull cord isolation switch or 3-pole extractor fan isolation switch

- Suitable lengths of 1mm or 1.5mm 3-core and earth cable

- Suitable lengths of 1mm or 1.5mm 2-core and earth cable

- Suitable pattress box for switch (if needed)

- SDS drill (if going through the wall)

- Core drill bit (if going through the wall)

- Correct ducting (if installing from scratch)

- Aluminium tape

- Large jubilee clips

- Internal and external fan vents (if installing from scratch)

How to Wire a Timed Extractor Fan Unit

As there are several different ways that a timed extractor fan is wired up, here we will cover the most common method; Taking a power feed from an existing bathroom light.

For completeness we will also cover how a standard bathroom extractor fan is wired up to it’s own switch and not an existing light switch.

Wiring a Timed Extractor Fan That’s Turned on by an Existing Light Switch

Extractor Fans with an integral timer or timed switch need a 3-core and earth supply to allow the unit to run on after a light is switched off.

It must also be possible to isolate the fan by means of a pull cord switch inside the bathroom, or a fan isolation (3-pole) switch outside of the bathroom.

Isolation switch for use in bathrooms and special areas for isolating circuits

Step 1 – Isolate Power:

Before anything is done at all the very first job is to isolate the power to the circuit you will be working on! This means pulling out the fuse or turning off the MCB for the lighting circuit the bathroom light is getting power from.

Step 2 – Install Fan Isolation Switch/3-Pole Switch:

Once isolated, the next job is to install the fan isolation switch/3-pole switch. Where this is done will depend on the switch you have.

If you are using a standard 3-pole pull cord switch, the switch is generally fixed to the ceiling and wired down from the top. However, this is normally when it’s being installed in an upstairs bathroom and there is decent access to the top of the ceiling from the loft.

If this is in a ground floor bathroom, you may need to pull up some floor boards to access and wire up.

If you are using an extractor fan isolation switch, these are generally installed outside the bathroom above the door. Again these are best wired up from the loft first cutting a hole (if plasterboard – see our installing plaster board pattress boxes project here) or chasing out if working with bricks and blocks (see our cutting and filling chases project here).

Again, if you are working on the ground floor then you may need to pop up some floor boards from above to run cables and access existing lighting circuits.

Once the pattress box is installed, cut a suitable length of cable with plenty of slack to run from the existing light ceiling rose you are taking your power from down to the isolation switch.

Strip both ends of the cable to suitable lengths (manufacturer should state this in their instructions, if not see our stripping cable project here) and connect the switch end cable to the correct terminals.

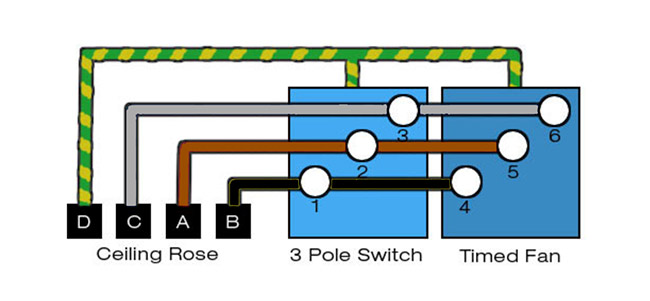

In this case as 3-core cable is being used this will be the black wire to the permanent live (add some brown tape/sleeve to signify it as live), the grey wire to neutral (add some blue tape or sleeve), the brown to switched live and the earth to the earth (make sure earth sleeve is added first) as in the image below.

Step 3 – Install Fan:

Next, the fan itself needs to be installed. How this is done will depend entirely on what type of fan is being installed.

If installing an inline fan, this will need to be positioned and screwed down to a flat and level surface, ideally between the point that air is being extracted and then being expelled.

If however an axial fan (one through the wall) is being installed this will need to go on an outside external wall.

Firstly however, a hole for the fan will need to be drilled through the wall. This is normally done using a core bit and SDS drill. See our core drill project here for more information. Once the hole is drilled, the fan body can then be roughly sited. Don’t fix it yet as it needs to be wired up first.

Step 4 – Install Fan Pipework:

If you are installing an inline fan then you will also need to install the associated pipework that will carry the moist air from the source to the outside.

There are several types of pipework but generally it’s best to use the PVC type as when using the aluminium round duct, the fan can echo through it when running creating quite a bit of noise, whereas the PVC type is generally silent.

If you are installing an axial through the wall type fan then you may need to run a short section of pipe between the inner and outer sections so that it bridges the cavity as you don’t want to be pumping moist air down into your empty cavity as this will cause untold amounts of issues.

When connecting up the pipework make sure that you first tape the pipe to the fan body using aluminium tape and then also screw up a large jubilee clip around the pipe. This will ensure a full and compete seal.

In terms of each end when installing an inline fan, you will need both internal and external extractor fan vents.

A larger diameter hole (stated in the instructions) is drilled in the ceiling above the shower, bath etc. and the vent is inserted and fixed up after the end of the pipework is fixed. The same is done at the other end in a suitable location to vent the moist air, normally through a soffit closer or fascia board.

Step 5 – Wire up Fan:

Once the fan is positioned, the next task is to get it wired up. A suitable length of cable is cut to run from the 3-pole switch out to the fan.

Again, if installing a axial fan through the wall you may need to chase out a section of wall to run the cable to the fan.

Once the cable has been run, both ends are stripped and then the switch side is connected up with the black to the permanent live (add brown tape/sleeve to indicate it as live), brown to switched live, grey to neutral (add some blue tape/sleeving) and earth to earth point.

The other end is connected to the timed fan terminals as stated by the manufacturer in the instructions provided with the unit.

Once all connected up, place the cap over the terminals on the fan and ensure the switch is installed correctly in it’s pattress box. Finally check all terminals and make sure they are tight

Step 6 – Test Installation:

Finally once all connected up the power is turned back on and the electrician then tests the installation fully to make sure all is well and correct and also that the timer turns the fan on and off for the set amount of time.

With most fans there will be 2 or 3 different settings that can be used. Once this is done, the circuit is isolated once more until the finish is completed. He then writes up and issues the works installation certificate.

Step 7 – Clean up:

The final job is to then do the finishing works. If you have created any chases these need to be filled.

Firstly the cable is capped over using a PVC capping or piece of trunking. This then protects the cable in the wall.

Once capped over any chases are then filled using a suitable type of filler or plaster. Once dried it can then be sanded flat with the surrounding surfaces and then finally painted.

If you haven’t created any chases, ensure that any cables are clipped up correctly, pipework is secure and the fan unit fixed securely to a flat surface. For through the wall-type fans, ensure both sections of the unit are fixed to the wall. Once all finished, the power is then turned back on and the fan can be put to use.

The wiring diagram below shows the wiring setup you need to connect your new timed fan to your existing light circuit ceiling rose so that when the light is turned on, so is the fan.

Diagram showing wiring method for a timed fan

- D = Earth Connection = To all units – This wire should be sleeved in a green/yellow earth sleeve

- C = Neutral Connection

- B = Permanent Live Connection

- A = Switched Live Connection

As we have stated above, if an extractor fan is being installed from scratch then this will need to be done by a qualified Part P registered electrician. However is you are simply replacing an existing broken unit then you are able to do this yourself.

Despite this, if you are unfamiliar with working on and around electricity then you are better off getting the pros in to do it for you!

Wiring a Timed Extractor Fan Switched on by its Own Switch

If you are unable or don’t want the fan wired off of the lighting circuit and want independent control then an independent switch will need to be installed.

We have concentrated on the actual wiring in this section, rather than the other elements of the installation. If you want to know about these, simply work through the steps in the section above.

Step 1 – Isolate Power:

As with all electrical work, before anything is done at all, make sure that the circuit being worked on is fully isolated in the fuse box or consumer unit. To do so, either pull out the fuse or turn off the MCB.

Step 2 – Install Isolation Switch (if needed):

The supply for such an appliance can in most cases be taken from most existing circuits, both lighting and sockets, providing a fused connection unit (FCU) is present at the start of the installation and appropriately fused to protect the sub-circuit cabling and accessories.

Typically, a 3A or 5A fuse is used for a fan installation of this nature, but be sure to check the manufacturers specifications for exactly what size fuse you should use.

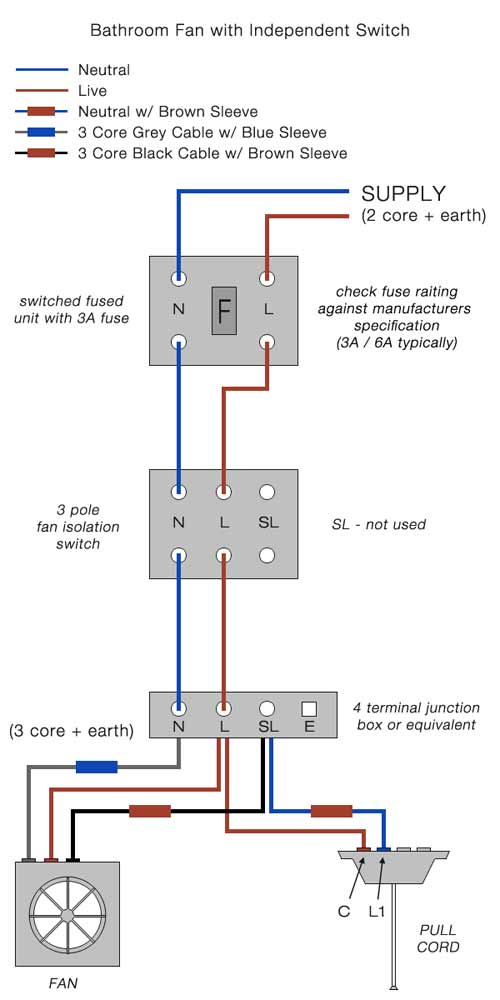

From the fused connection unit the installation must then have a 3-pole isolation switch that provides at least 3mm of separation on ALL live conductors when the switch is off.

In this instance, the switch live (SL) connection is not used but it is recommended that a 3-pole switch is still fitted as it would allow the circuit to be reconfigured to work with the light switch in future if desired.

The 3 pole switch ensures complete disconnection of supply to the fan so that maintenance can be carried out safely, without the need for a qualified electrician to disconnect the wiring (N.B. if you are in anyway unsure of how to carry out routine maintenance/cleaning on the fan, you should always seek the advice of a qualified electrician).

As with the steps above, either a shower isolator switch is used that is normally installed outside the bathroom above the door or it’s possible to use a 3-pole pull cord switch that is usually installed in zone 3 inside the bathroom.

Step 3 – Find Power Source:

As we have mentioned above, you can take power from pretty much any location for an extractor fan, both lighting and socket circuits can be used once you have installed the FCU and the 3-pole switch. Generally, power is taken from the easiest circuit that can be reached. A junction box is used to connect everything up safely.

From the FCU, the 3-pole isolator switch is connected up using a suitable length of cable that’s stripped at both ends. It’s connected between the 2 units, neutral terminal to neutral terminal, live terminal to live terminal and earths to earths.

In a similar manner, the junction box for the live feed is then wired to the FCU, again, each wire connected to the correct live, neutral and earth terminals.

This then enables the independent pull-cord switch to trigger the fan, and allow it to run on, in accordance with the timer setting when the fan is switched off.

Step 4 – Wire up Junction Box and Fan:

A 4-termial junction box is required to connect up the fan, 3-pole switch and the pull switch, and is wired similarly to a ceiling rose or light junction box, utilising connections for earth, neutral, (permanent) live and a switch-live.

Firstly the supply from the 3-pole isolator switch should be connected in to the junction box using a suitable 1mm or 1.5mm twin and earth cable to the L, N and E terminals.

Next, the fan should then be connected using 3 core and earth cable (depending on the model the earth may not be required), with the extra cable being used as the switch-live (SL).

Due to the colours of 3-core cable (brown, grey and black), certain conductors will need an appropriate blue or brown sleeve over them, to denote their use within the circuit (see diagrams below).

We recommend using the brown cable for the permanent live (L), the grey cable (sleeved blue) for the neutral (N) and the black cable (sleeved brown) for the switch-live (SL).

Step 5 – Wire up Fan Switch:

Finally, connect the pull-cord switch that wil be used to turn the fan on and off into the junction box using normal 2-core cabling as with any other light switch.

When connecting up, its necessary to ensure the brown is connected to the permanent live terminal in the junction box and the common (C) in the switch, and the blue cable (sleeved brown as it is not being used as a neutral but as a live conductor) is connected to the SL (switched live) terminal in the junction box and L1 in the switch.

Also remember that all earths need to be connected together within each enclosure in the circuit.

Step 6 – Test Installation:

Finally once everything is connected up, the last job is to turn the power back on and test the circuit to make sure all is well. Once this has been done your electrician will then issue you with a works certificate to state that all has been done to the required regulations.

This wiring diagram shows an easy to follow configuration for a bathroom extractor fan fitted with a timer, that’s not going to be turned on by the existing light switch. Instead, we are going to install a new switch that will turn the fan on and off.

There are other ways to achieve this where the junction box connections are housed within the 3-pole isolation switch, but that is more complicated to explain and increases the chances of something going wrong.

However, using the method explained above, each stage of the installation can be easily followed and easily checked for errors or problems in the future with minimal risk of confusion.

Diagram showing wiring method for an independently switched extractor fan

Although the fresh installation of a timed extractor fan unit should only be attempted by a Part P registered electrician, if you just need to replace an existing unit as its broken then you are allowed to do this. Although the above guides look at the installation from start to finish, all the information to swap out your broken unit can be found also.