Wiring another socket from a socket is called creating a spur socket in the trades and is a technique that is used to quickly create a new socket location.

Adding a spur socket to an existing ring main or radial circuit is a fairly straight forward job and simply involves tapping into existing wiring, however there are numerous rules you need to be aware of. Find out what these are and how to wire up a spur socket below.

What is a Spur Socket

A spur socket is where an existing radial circuit or ring main is tapped into with new wires via a junction box or socket and a feed is taken to supply a new socket in a new location.

This can be very useful in situations where there may not be enough sockets in a given room to power required appliances and you would otherwise have to resort to running extension cables and the likes, which can be rather dangerous.

New spur socket taken from existing ring main

Rules for Spur Sockets

Although it is possible to fit a spur socket on a DIY basis there are quite a few rules that need to be followed to ensure it’s done safely, these are as follows:

- A spur can be connected to an existing socket, on either a ring main or a radial circuit, providing that socket does not already have a spur. There can only be one spur per socket

- The total number of spurs must not exceed the total number of sockets already on the radial or ring circuit

- The spur must be connected to the existing circuit using the same size and type of cable as used in the main circuit you’re spuring from. Normally 2.5mm twin and earth

- There should be no more than 1 new socket on the spur

- Only 1 spur can be connected per socket or junction box

- The cable used for the spur should be no longer than 3m

- The cables to and from any spurs you connect must be protected by a conduit of some kind; be it on the surface or buried in the wall

- If you bury cables in the wall they must only run vertically, not horizontally

- Cables may be placed in floor or ceiling voids but not amidst, or wrapped in insulation as they can become too hot, over heat and catch fire

- There are also rules that govern the length of ring and radial circuits that limits the length of cable you use, no more than a floor area of 100 square metres, and long spurs can exceed those limits

- There is also a minimum distance a socket can be from floor level and any corners, see our socket height information project for more details

In some cases when wiring up a spur socket, you may find that the existing wiring in your home is using the old wiring colours. If this is the case, see our new wiring and cable colours project for help matching old wires to new.

If creating a spur means that any of the above rules are affected you must not install one! If you absolutely must create some new sockets, the only way you can do this is by adding another ring main or by extending an existing ring main.

Part P of the new building regulations could involve a check on any additional circuitry by qualified electricians when you sell your home. If any wiring is not up to standard, then it can affect your sale, you could be breaking the law. Additionally, your house insurance may not be valid. Please be absolutely sure you know what you are doing and get all of your work checked by a qualified electrician.

How Many Sockets on a Spur?

In terms of how many spurs there can be, there can only be one spur per socket or junction box. This is to ensure that the socket or junction box you’re spurring from doesn’t get overloaded.

In the event there is too much draw on teh spur, things can get very hot and eventually catch fire!

How do you Tell if a Socket is on a Spur?

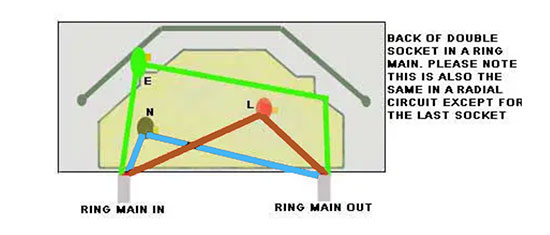

A general rule for a ring main is that if you only have two cables in the back of an existing socket then it is ok to spur.

However, if you have a radial circuit with two cables coming in and out, this may be the last socket on that circuit and already has a spur.

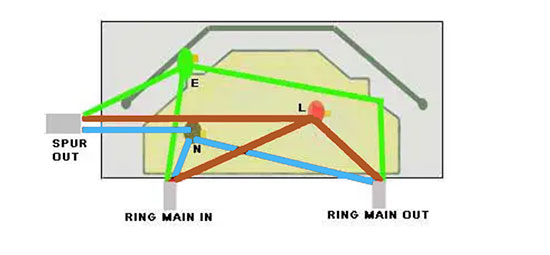

When looking at the rear of a socket face plate, for both ring mains and radial circuits there should be one wire coming in from the previous socket and one going out to the next, any more then this is a sign there may already be a spur running from this socket.

Rear view of socket face plate showing cables running in and out

Rear view of a socket showing cables in and out and also a spur connected

Ultimately it’s rather difficult to identify the type of circuit you are trying to tap into, to create a spur without the necessary equipment and knowledge to test it, however one of the safest methods is to trace the cable directly from the consumer unit and then back again (ring main) or to the point that it ends.

This way you can inspect it along it’s full length for any junction boxes, however this won’t necessarily tell you if any socket have been spurred from.

To ensure that no other spurs exist, the safest method is to find the supply cable for an existing ring main and then tap into this and take a feed using a 30amp junction box. This way you know that there are no other spurs present.

If you are in any doubt at all as to which cable you are safe to use, please check with a qualified electrician. It’s not worth the risk getting anything wrong.

Can I Legally Add a Spur Socket??

In answer, yes you can add your own spur socket to an existing electrical circuit in your home as well as light fittings and switches as long as you abide by the rules and that the location you’re installing in isn’t a special location such as a bathroom.

Although you can add your own spur sockets, switches etc. this does rely on the fact that you do actually know what you are doing in terms of running cables, connecting up etc. If you are in any doubt you should call a professional electrician.

DIY installed spur socket

What do you use to Create a Spur?

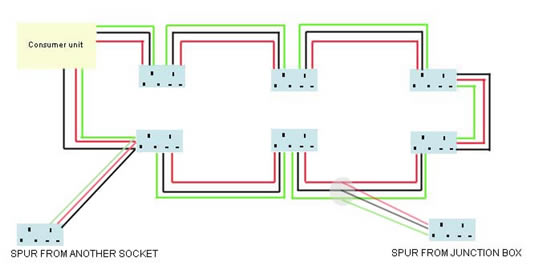

There are several ways that you can create a spur socket from an existing ring main or radial circuit and that is to take a feed from an existing socket or you can use a 30amp junction box to take a feed out to your new socket.

The slightly easier and more straight forward method is to use a junction box. This is mainly due to the fact that you can choose your install location and ensure there is plenty of space so you’re not struggling to see when connecting things up.

The wiring for a junction box can be seen here. Junction boxes come rated for different uses by the amps they are allowed to carry. Only a 30amp junction box should be used on a ring or radial circuit feeding a spur socket. The junction box must be fixed solidly to a suitable surface and must not just "float around suspended by the cables it joins.

Using an existing socket faceplate is more acceptable, however it can be a little more tricky in terms of running new cable to it and also adding an extra set of wires to the terminals on a faceplate can be quite tight, so it you’re new to this then it’s probably best to go the junction box route.

Standard example of a ring main with a spur from a socket and one from a junction box

Tools and Products Needed to Install a Spur Socket

To successfully install a new spur, you will need the followinfg tools and products:

- 30amp junction box

- Suitable length of cable to run to new spur

- Utility knife

- Wire cutters

- Wire strippers

- Small flat screwdriver

- Philips screwdriver

- Chasing machine (if needed)

- Hammer and bolster

- Chisel (for notching timbers)

- Plasterboard saw or multi-tool and suitable blade

- Electricians cable fishing tape

- Filler

- Filling knife

- Sandpaper for sanding filer flat

- Sanding block

- back box – metal for solid wall, plasterboard for plasterboard wall

How to Install a Spur Socket

For the purposes of this example we are going to be using a 30amp junction box to install a new spur socket and we are going to tap into the supply cable for an existing ring main in the loft.

Step 1 – Plan out Spur Socket

The first step is to plan exactly where the new socket is going to go and how you are going to run the new cable from the point you tap into the ring main out to the socket.

Firstly, measure and mark the location for your socket on the wall making sure that it’s at the correct height from ground level and from any corners. Place a back box on the wall, level it up and then draw around it, marking where it needs to be cut out.

Next, find out what type of wall you’re working with e.g. whether it’s solid brick or block or plasterboard. Once you know this will give you an idea of how you will need to run the supply cable.

Brick or Block Walls

For brick and block it may be easier to pull up floor boards and run supply wires from here as you will only have a small section of wall you will need to chase out, unless you want to surface mount the cable in trunking.

However pulling up floorboards, carpet, laminate etc. can be a nightmare and might not be possible so it may be easier to run your cables form the loft, through the ceiling and then down the wall.

Plasterboard Walls

If dealing with plasterboard then it may be possible to run your new cable down the cavity inside the stud wall, however quite often there will be a horizontal stud running across the cavity that will prevent you dropping a cable down.

In this case you can cut a small section out the face of the plasterboard and notch the timber stud with a chisel, run the cable around it and then repair the hole.

Alternatively you can again lift some floorboards and come up through the cavity from the base. In either case you will need to fish the cable through. Find out how to do this in our fishing electrical cables project here.

Ideal location for tapping into existing ring main for spur socket

Step 2 – Install Socket back box

Once you have planned out exactly where you are going to run your cable and install the socket, it’s time to install the back box.

If fitting in a solid wall, use a chasing machine, breaker or hammer and bolster to chop out the back box markings made on the wall to the depth of the back box and then chase out a section to run the cable to it (either up form the floor or down from the ceiling). This is best done using a chasing machine

Fix the back box in place using screws and wall plugs.

If plasterboard, first cut out the shape of the back box marked on the wall and then tidy up the cut. Don’t install the back box quite yet as the larger gap will make it easier to pull the cable through.

Chase cut out of solid wall ready for cable

Step 2 – Run Cable

The next job is to run the supply cable. From the location you’re tapping into the radial or ring circuit, leave a good 6 – 8 inches of cable for wiring the junction box. Make sure it’s clamped or held in place so it doesn’t get pulled away.

Run the other end along the route you previously planned to the site of the socket. If solid wall, again allow a good 8 inches at the socket end for wiring. Make sure the cable is run flat in any chases and then covered with PVC conduit in the case to protect it.

If plasterboard, use a stud detector to detect any horizontal studs and if there are any, mark and cut the face of the plasterboard out either side of the stud. Notch the stud out to the depth of around 15mm using a chisel.

Run your supply cable from the radial or ring main location, down the stud cavity, around any timbers (if any present) and then on to your new socket. Allow a good 8 inch tail for wiring up the socket.

Take the back box and slot it over the end of the supply cable and then push it in place into the hole, ensuring that the wings clip in fully holding it in place.

If you have had to make any holes then they will need to be repaired. See our project here on repairing holes in plasterboard for more help.

Electrical cable tails in back boxes ready for connecting up

Step 3 – Connect up Socket

One of the final jobs to do now is to connect up the socket. Holding the cable tail against the back plate, estimate how much needs to be stripped to reach each terminal and then strip off the outer cable sheath.

Next, strip 100mm or so from the end of each core live and neutral cable and then bend the stripped area in half. Place some earth sheath over the earth cable and then do the same for the earth.

Connect each wire to it’s correct terminal; Brown live to live, blue neutral to neutral and earth to earth.

Once connected, screw the faceplate on to the back box

Socket faceplate screwed on to back box

Step 4 – Connect Junction Box

Finally you can now connect the junction box to complete the circuit. Before doing anything, isolate the circuit you’re working on at the consumer unit or fuse box. Place a note to say what you’re doing incase anyone turns it back on!

In a suitable location, cut the ring or radial cable in half using some wire cutters. Estimate how much outer sheath needs to be stripped to allow the inner cores to reach the terminals and strip it away for both cut ends, and also for the end of your new supply cable.

Next, strip 10mm or so from the end of each core wire for each of the 3 cables. Once done connect each wire to a terminal in the junction box, ensuring that the same core from each cable is connected to the same terminal e.g. all lives to one terminal, all the neutrals to another and all the earths to another one.

Ensure the terminals are screwed down tight and the junction box is firmly fixed to a surface and then screw the cover back on.

Test the new circuit correctly and ensure all is well and good.

The final job to do is to fill any chases and make any other repairs necessary and once done you can then set your new sour socket live for use.

Filling a chase to the level of the surrounding surfaces

Fused Spurs

As we have stated above, you can only wire a single spur socket from an existing socket or junction box, however if you need to add more sockets than one it’s possible to add more, but first you will need to install a fused connection unit or FCU.

The fused connection unit needs to be installed between the existing socket or junction box you are taking the feed from and your new sockets.

Its purpose is to protect the new spur of sockets and the existing circuit you’re taking power from as in the event of an issue or overload, the fuse in the fused connection unit will blow, killing power to the sockets and protecting the radial or ring main the feeds taken from.

To find out more about FCU’s, see our project here on wiring a fused connection unit.

Fused connection unit or FCU

Adding a spur socket to an existing radial circuit or ring main can seem like a tricky job the first time, but as long as the circuit is isolated and you abide by all of the rules it’s something that turns out is quite straight forward.