If you don’t currently have a shower it’s well worth considering installing one as over time it may save you a great deal of funds and there are numerous different types such as the thermostatic bar shower (if you have a boiler), or often more simply, an electric shower. Find out what’s involved below.

Regulations and Safety Information for Electric Showers

Safety is paramount when dealing with any form of DIY, but never more so than when dealing with electricity. Regulations now insist that ALL domestic DIY electrical work is checked by a qualified electrician and a minor works certificate issued. Failure to do this could render your house insurance invalid and make selling your home very difficult.

With this in mind you are not allowed to install an electric shower yourself unless you have the necessary skills and knowledge to fully test it e.g. you are a trade professional. For more information please see our project here on Part P Building Regulations.

Additionally, as a shower is installed in what’s known as a “special location” (see our project on bathroom zones here for more info), once installed it needs to be signed off and that can only be done by a Part P registered electrician.

This is even the case if you are simply swapping an old shower unit for a new one of exactly the same type!

You may also be aware that years ago cable colours were harmonised to those used in Europe and due to this, if you have an older home, you may still have the older wire colours. More information on this can be found in our wire colours project here.

Finally, for any more information on staying safe when working on or around electricity, see our electrical safety project here.

What to Check Before Installing an Electric Shower

Before you even settle on the fact you want an electric shower, you should first check your consumer unit (or fuse box) and the size of the supply coming in to your property.

Large showers use a lot of power (or load), similar to that of an electric oven, and this can cause issues on older installations that may have consumer units that are not capable of handling this extra load.

As a rule of thumb, if you have a 60A or 63A main switch, then your supply fuse will likely be 40A or 60A, if it is 80A or 100A the supply fuse will likely be 60A, 80A or 100A, quite often a phone call to your electric supply company can resolve this and tell you exactly what setup you have.

NEVER break the seal on your incoming fuse holder to look at the fuse, this is illegal and could lead to prosecution.

If your supply company are unable to help, your only solution then is to call in a professional electrician.

Incoming fuse holder in domestic electrical setup

Common Shower Ratings and Protective Devices

One of the most common questions that gets asked is; What size electric cable is needed for an electric shower? As with many situations like this, the answer is, it all depends on how much it draws and its power in kW (kilowatts).

As a very rough guide, for a shower rated at 6kW to 7kW, 6mm2 cable should be used. For a shower rated at 7.5kW to 10kW, 10mm2 cable should be used and for a shower rated at 10.5kW to 11kW, 16mm2 should be used.

This is a very rough guide however and table 1 below gives full information and figures for common shower ratings and the protective device and cable required to install them safely.

Table 1 – Cable Size, Protective Device and Device Type Specs

| Standard Shower Rating Watts (kW) | Maximum load from the supply Amps | Maximum size of Protective device (fuse, MCB) | Recommended Minimum Cable Size (in conduit in insulating wall) | Recommended Protective Device |

| 6000 (6kW) | 26 | 32A | 6mm2 | RCBO |

| 6500 (6.5kW) | 28.2 | 32A | 6mm2 | RCBO |

| 7000 (7kW) | 30.4 | 32A | 6mm2 | RCBO |

| 7500 (7.5kW) | 32.6 | 40A | 10mm2 | RCBO |

| 8000 (8kW) | 34.7 | 40A | 10mm2 | RCBO |

| 8500 (8.5kW) | 36.95 | 40A | 10mm2 | RCBO |

| 9000 (9kW) | 39.13 | 45A | 10mm2 | RCBO |

| 9500 (9.5kW) | 41.3 | 45A | 16mm2 | RCBO |

| 10,000 (10kW) | 43.47 | 45A | 16mm2 | RCBO |

| 10,500 (10.5kW) | 45.65 | 60A | 16mm2 | RCBO |

| 11,000 (11.0kW) | 47.82 | 60A | 16mm2 | RCBO |

All data in the table above has been compiled with reference to BS7671:2018. The IET Wiring Regulations. Cable Data taken from Table 4D2A. Page 158 On-Site Guide.

Note: We have assumed the that all cables will be enclosed in conduit in a thermally insulated wall. However if they are not and they are enclosed in a conduit or trunking on a wall the current carrying capacity of the cable is slightly higher. Refer to the table in BS7671:2018 mentioned above for precise figures.

Additionally no account has been taken for volt-drop or diversity. Applying diversity to a shower supply is not recommended unless the shower to be installed is fully thermostatic in operation.

It’s also worth mentioning that although you could have a 10 or 11kW shower installed, in reality there really is no need at all. A good quality 9, 9.5kW shower will be just as good.

What Size Cable and MCB/RCBO/Fuse to use for an Electric Shower

As is the running theme with this subject, the size of cable and MCB/RCD/RCBO that should be used to install an electric shower will very much depend on how much draw or power the shower will use.

If the shower only has two power settings, then no diversity should be factored into the load calculation. This is because the shower will work on 50% or 100% of full load, the temperature of the water being regulated by the flow rate through the shower heater unit.

Note: In terms of electrical diversity, this is essentially an allowance of a load and it is assumed that this load is unlikely to be used at the same time. This is added as a factor.

When doing a calculation for the shower circuit it is wise to consider volt-drop and other factors when considering the size of cable to be used. If the shower is a fully thermostatically controlled unit, then a diversity factor may be assumed of not less that 80%.

For information on likely voltage drop in certain installation setups, see Tables 4D2B and 4D5 of BS7671:2018 On-Site Guide, pages 160 and 161.

Wherever possible showers should always be protected by an RCBO, this is a device that does the job of both an MCB, to provide overload protection and short circuit protection, and an RCD to give Earth Fault protection, so the circuit is protected in 2 ways.

Showers should not, ideally, be protected by Semi-Enclosed Re-wirable fuses (old-style fuse box), if this means fitting an additional consumer unit beside your main consumer unit, then this is the best way to proceed. Fuses should only be used as an absolute last resort.

Fuses take higher fault currents to cause them to “blow” than either MCB’s or RCBO’s, up to 1.8 times the rating of the fuse wire in the holder in some cases.

Water and Electricity are a dangerous mix, the current drawn by even a small shower will likely prove fatal in the event of something going wrong or it being installed incorrectly.

Electric showers should always be installed using, at minimum, an RCD or ideally an RCBO. The RCBO is the better option as this gives overload, short circuit and Earth fault protection.

Please note that some shower manufacturers demand the installation of an RCD/RCBO, if this is the case, failure to do so could invalidate your warranty so it is advisable to follow this demand.

32A RCBO for use with some electric shower installations

What Size Electric Shower can I Install?

When you know the size of the supply you have at your consumer unit or fuse board from your supplier, you can use the above table (Table 1) as a reference guide to see the maximum size of shower your installation can support.

To determine this you will need to take into account all of the electrical appliances that may be running when the shower is in use. Common heavy load items in modern homes are Washing Machines, Tumble Dryers, Dishwashers, Combined Cookers (oven, grill, hob), Electric Hobs, Electric Ovens, kettles and the good old Immersion heater in older properties.

One thing to bear in mind at this juncture is that the main isolator of a consumer unit is also a limiting factor in the size of shower you can install, if you can install one, regardless of the fuse/MCB/RCBO in your supply.

The Table below is equally accurate as a guide for this thorny problem as it references the size of the main switch in the consumer unit.

You need to ensure that the load drawn by the shower when in use will not cause your supply to be overloaded. For reference see table 2 below.

| Maximum Supply of CU Isolator/Fuse Rating | Common Circuits Example Only – Not Definitive | Recommended Maximum Shower Rating |

| 40A | 1 Ring Main, 1 or 2 Lights, 1 Boiler | Not Recommended |

| 60A | 2 Ring Mains, 2 Lights, 1 Boiler | 7kW |

| 80A | 1 Cooker, 2 Ring Mains, 2 Lights, 1 Boiler | 7 – 9kW |

| 100A | 1 Cooker, 2 Ring Mains, 2 Lights, 1 Boiler | 7 – 9kW |

The above should only be used as a guide, individual installations vary considerably, and to list all possible scenarios would take more space than is available or practical.

Installing an Electric Shower

OK, so you know the size of shower you want, and you know the size you can have, the problem now is installing it safely.

As commented, this can only be done by a qualified Part P registered electrician due to the testing that has to be done to confirm it’s safe for use, however, so that you know exactly what steps are involved, we have detailed them below.

Step 1 – Where to Place MCB’s/Fuses in Your Consumer Unit

One very important point to be aware of is if you have to add any new MCB’s or fuses to your consumer unit or fuse board, where they should be placed.

Believe it or not there is a particular order in which MCB’s and fuses should be positioned as all large loads should be placed as near to the main isolator of a consumer unit as is possible.

Therefore if you have to add a new breaker for your shower, you are advised to move all breakers along one place to ensure that the new circuit breaker for the shower is either in place adjacent to similar rated breakers, or if it is the largest, nearest to the isolator.

Should you find yourself in a position where you must use fuses to protect the shower, the same advice still applies.

One important thing to remember is that some manufacturers state that certain consumer units they produce will only support the use of one MCB rated higher than 32A, this will be true for any consumer unit with either a 63A or 80A main Isolator or RCD, because it simply can’t handle anymore.

In some cases it may be possible to upgrade this Isolator to 100A, however you should seek advice from a professional electrician on this as your supply may not support this higher load.

You will also need to have your supply disconnected temporarily in order to change the Isolator or RCD, as you would imagine, this is not a DIY job as it’s not only illegal to break the seals on Meters and Main Fuses, but work of this nature can only be done by a Part P registered electrician.

Further, your existing consumer unit may not be suitable for a higher rated Isolator or RCD and in most cases only a professional electrician will be able to tell this.

Step 2 – Running an Electrical Supply Cable for an Electric Shower

The first task is to run a new electrical supply cable to the install location for your shower. This will run from your consumer unit or fuse board.

When deciding the route your cable will take, ensure that you take the shortest route wherever possible and practical. This is because the current drawn through the cable will cause a loss in voltage (volt drop) over extended lengths of cable.

The higher the current load, the greater the volt drop. The regulations say this must not exceed 4% (=9.2V AC ) of the nominal supply voltage of 230V (AC) over the length of the circuit. Normally in domestic situations this is not an issue but must you must bear this in mind.

Never route cables near sources of heat, such as central heating pipes or hot water pipes, the extra heat could damage the cable but also impede its ability to carry the full load of the shower without suffering damage and if the draw is significant, it could possibly overheat and catch fire.

Higher temperatures reduce the current carrying capabilities of cables. Try not to route cables through insulation, and NEVER if the insulation is Polystyrene, this will damage PVC insulated cable.

In pretty much all cases, routing the cable through the loft will be easiest as everything should be accessible, however if you don’t have a loft (loft conversion) you may need to lift floorboards which can get tricky.

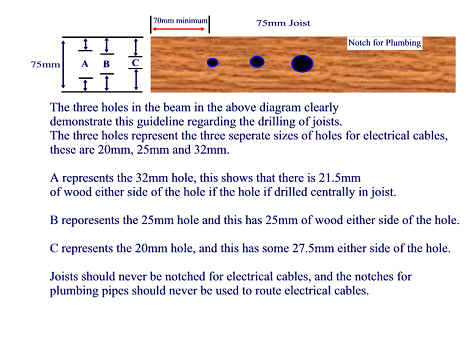

You may find that you need to drill holes through joists to get from the consumer unit to the shower, if this is the case, ensure that the holes you drill are in the middle of the joist and are large enough to safely route the cable through. See our project here on notching joists for more information.

20mm diameter holes are adequate for 6mm2 cable, but for 10mm2 you will need 25mm diameter holes, and for 16mm2 cables, a whopping 32mm. Be careful when drilling holes of this size, ensure there is at least 50% of the joist still intact (25% above and below the hole) as you could damage the structural abilities of the joist.

Never drill a hole in a joist within 70mm of the end of the joist, you may damage the structural abilities of the Joist to do its’ job. See diagram below.

Drilling a Joist

Try not to twist the cable when installing it, this will not reduce its electrical properties, but it will make it harder to install and more likely get damaged as it’s pulled through.

If the cable is to be buried in a wall at any point of the circuit, most likely in the shower room, always cover it over with METAL capping.

This metal capping should be carefully, but firmly secured to the wall to ensure the cable is protected before you plaster over it and then install the shower cubicle etc.

It is not recommended that you use plastic capping for this type of supply. When fixing the capping, be VERY careful not to damage the cable underneath. Lack of care here could be dangerous, but most certainly costly.

Once the cable has been run from the consumer unit, before it reaches the shower it must go through an isolation switch before it then goes on to the shower.

Note: connecting it to the consumer unit is generally the very last job as when it’s not connected it can be easily worked on without fear of electrocution.

Step 3 – Fitting a Local Isolation Switch

All electric showers that are installed are required to have a local switch or isolator. These must be manufactured to relevant British Standards, be of the correct rating for the size of the item it’s supplying and be located so as to prevent a person using the shower from operating the switch.

Similarly, it should be located so as to prevent it from being suddenly exposed to moisture. Generally it’s installed outside the bathroom above the door, however it can also be installed as a ceiling-mounted pull cord switch somewhere in the bathroom

Regardless of type, it must incorporate a neon indicator that illuminates when the supply to the shower is switched on.

Wall mounted switches are easier to terminate larger cables in, but ceiling mounted are suitable for cables up to 6mm2 easily, 10mm2 with care. If you’re running the cable through the loft then this can often make it much easier to connect up.

For showers rated at 10.5kW and above a switch capable of handling loads up to 50A is required, such a switch is the MK 3164WHI, this is a pull cord switch however.

Care should be taken when mounting these switches, they need to be secure so ensure that you can get a secure fixing. One trick is to cut a piece of 18mm plywood or MDF large enough to fit the space between your joists, whether in the loft or floor space, this should be about 300mm (12”) long.

In the middle of the switch drill a hole large enough to pass both cables through. Place the wood over the area you wish to fix the switch, making sure to line the holes in the wood and ceiling up. When the wood is in place, use four 50mm (2”) screws to hold the wood in place.

This will give you a firm and secure mounting for the switch.

When connecting up the switch it will need to sets of cables, one running from the consumer unit and the other running to the shower unit.

Ensure that the right core from each cable is connected to the right terminal e.g. brown/red live wires to the live terminal, blue/black neutral wires to the neutral and both earths to the earth terminal.

Once connected up, the other section of cable is then run down to the shower install location.

Step 4 – Run Water Supply Pipework

With the cable run, the next job is to get a water supply in place. In pretty much all cases, modern showers only required a cold feed as they heat water on demand which is more efficient.

To get a cold water feed you will need to locate a nearby cold water pipe and tap into it. What pipe you use will very much depend on the plumbing pipe layout in your own home but generally you should be able to pick one up in the loft.

Failing this, as it’s the bathroom, a feed from the toilet, sink or bath can usually be taken fairly easily, but will normally involve having to lift floorboards.

To take the feed, more often than not Speedfit fittings are used as they are quick and easy to use (see our Speedfit fittings project here for more information).

To ensure any new pipework terminates in the right place for the shower unit, generally it’s placed on the wall and the water inlet is marked. The new pipework is then run to this location and normally a long tail is left hanging out the wall that’s cut to size when the unit is fitted.

Finally, Once the cable and water supply are in place, generally the tiling is then completed ready for the shower to be installed.

To find out more about ceramic tiling, see our project here on how to tile walls and floors.

Step 5 – Fix Shower In place

Once the wall is tiled and the grout dry the shower unit is then installed on the wall.

First, the water supply pipe is cut to the correct length so that it will slot into the inlet on the shower unit and allow it to sit flush to the wall.

Once done, the shower unit is fitted in place and the fixing holes marked. The unit is then removed, the holes drilled out and wall plugs are then inserted. The unit is then put back in place, the water supply refitted and the unit is then screwed to the wall.

Before it’s screwed in place, it’s essential to make sure that the electric supply cable is pulled through the appropriate hole so that it’s inside the unit, ready to connect to the required terminals.

Step 6 – Connecting and Wiring an Electric Shower

One of the final tasks that needs to be done now is for the shower to be wired up.

When the cable is terminated in the shower, it’s essential that the cable clamps provided are used to hold the cable firmly in place. It should be used to the clamp the outer sheath only and not the inner cores.

These plastic clamps are reversible depending upon which size cable you are using. It may be a problem if you have to use 16mm2 cable, as the clamp may not be large enough to support this size of cable.

When the inner core cables are stripped back, only enough for the wire to connect to the terminal is stripped and no more. No copper should be visible outside of the connection block.

The connections should be tight, not so tight as to damage the cable cores, but tight enough to ensure electrical arcing does not occur.

In terms of what goes where, the brown/red live wire should be connected to the live terminal, the black/blue neutral to the neutral terminal and the bare wire to the earth terminal.

The bare earth conductor in the cable is designed for use as the circuit protective conductor (CPC) or Earth, this must be sleeved using Green/Yellow sleeving to ensure it is clearly identified.

In the case that copper pipe has been used in place of plastic Speedfit, a short length of 4mm2 Green/Yellow PVC insulated earth cable should be connected to this water pipe supplying the shower. The other end is then connected to the earth terminal of the shower.

The connection to the pipe should only be made using a proprietary EC14 Earth clamp manufactured to BS951. The cable should be terminated to the clamp using an insulated crimp lug. This is necessary for earth bonding.

Depending on the layout of the shower “guts”, it may be advisable to sleeve the inner cores of the supply cable with heat proof over sleeving of the appropriate colour for that core.

Some showers may have the electrical connections close to the boiler of the shower, and the heat this produces may cause damage to the inner insulation of the cable over a period of time that could later result in an electrical fault.

Step 7 – Connecting to the Consumer Unit

Once all other points have been completed the final job is for the connection to be made to the consumer unit. Before this is done, the power is turned off using the main switch in the consumer unit, so all circuits are isolated.

The same care should be taken in the consumer unit as was taken when prepping the cable to connect to the shower unit. Ensure that the cable is firmly secured to prevent it accidentally being pulled out of the consumer unit.

If required, any existing MCB’s, fuses etc. are then moved away from the main isolator and a new fuse/MCB for the shower is inserted on to the board where is then connected up correctly.

When connecting the cable, the outer sheath is stripped back, ensuring that about 25mm of the outer white or grey sheath projects into the consumer unit, this can be taped up using (ideally) white PVC insulation tape, although other colours of insulation tape are available and equally safe for this use.

Any green/yellow sleeving should be put over the bare core before taping the end of the outer insulation, this will prevent it moving and exposing bare copper.

Again, only enough of the inner core wire should be exposed to make a neat job of terminating the cores securely, and only enough copper to enter the terminal without any showing outside it.

Check to ensure these terminations are secure, and then replace the cover of the consumer unit and turn on the main switch to restore power to all other circuits.

Testing an Electric Shower

With everything correctly connected and installed the shower is then tested to ensure the installation is correct and that it works as it should do.

The water supply is firstly turned on and all connections checked to ensure there are no leaks and that the water cylinder in the shower is full and primed. If it is not and you turn the shower on, you may burn out the heating element or cause other damage to the shower.

Before the power is turned on, all terminals are check to ensure they are screwed up tight and then the shower cover protecting the internals is then fixed in place.

Only once all of the above have been covered is the shower actually turned on. If all is well it should run with good pressure and heat up fairly quickly to the desired temperature set by the main control.

If so and all is well then the shower has been installed correctly. The electrician will then also carryout the other tests he needs to complete before issuing you with a works completion certificate for your records.

A Note on Bonding

A wise precaution that any good electrician will carryout is to check up on the earth bonding situation. All metal/copper pipework should be cross-bonded when installing an electric shower. All copper pipes should be cross-linked using EC14 Earth clamps, as described above, and lengths of 4mm2 green/yellow earth cable using crimp lugs on the ends.

There should be a main Earth bond linking your consumer unit earth terminal or the main earth terminal of the supply to both your Gas and water supplies, these bonds should be within 600mm of the consumer side of meter or stopcock. The cable used should be no smaller than 10mm2 Green/Yellow earth cable, in some cases they may be 16mm2.

Cable Ratings for Shower Installation and Reference Methods

Regular reader, Oliver made a great point which is worth mentioning:

One of the main issues with installing a shower is that the route to a shower isolator and shower is often through the loft which is commonly insulated up to 250mm thick. Any competent electrician would take this into account as this would de-rate the cable by 50%. So even 16mm2 cable should be de-rated to 8mm2 equivalent according to the regulations.

We cover this is more detail in our project all about cable sizes and amp ratings.

It is actually quite a complex issue that a qualified electrician will be experienced in dealing with, which is why it is only them that are allowed to do this kind on notifiable work. Essentially as a DIY enthusiast you need to know that where the cable is routed will affect the rating that you need to use.

There are tables, which we summarise on our cable size page (linked to above), in the regulations which can help a qualified electrician ensure that they have the right cable for where is it routed – this is referred to as the Reference Method.

Installing an electric shower is quite a complex job, with many different points that you have to be aware of that you won’t necessarily know as a DIY’er, hence the reason why this should only be tackled by a professional electrician with the necessary skills and knowledge.